Multifunctional microcrystalline soft film powder and preparation method thereof

A kind of soft film powder, multi-functional technology, applied in the direction of pharmaceutical formulations, toiletry preparations, cosmetic preparations, etc., can solve the problems of not too many types of functional ingredients, difficulty in meeting market demand, conflicting effects, etc., to eliminate Fine wrinkles, improved hydration, and improved anti-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

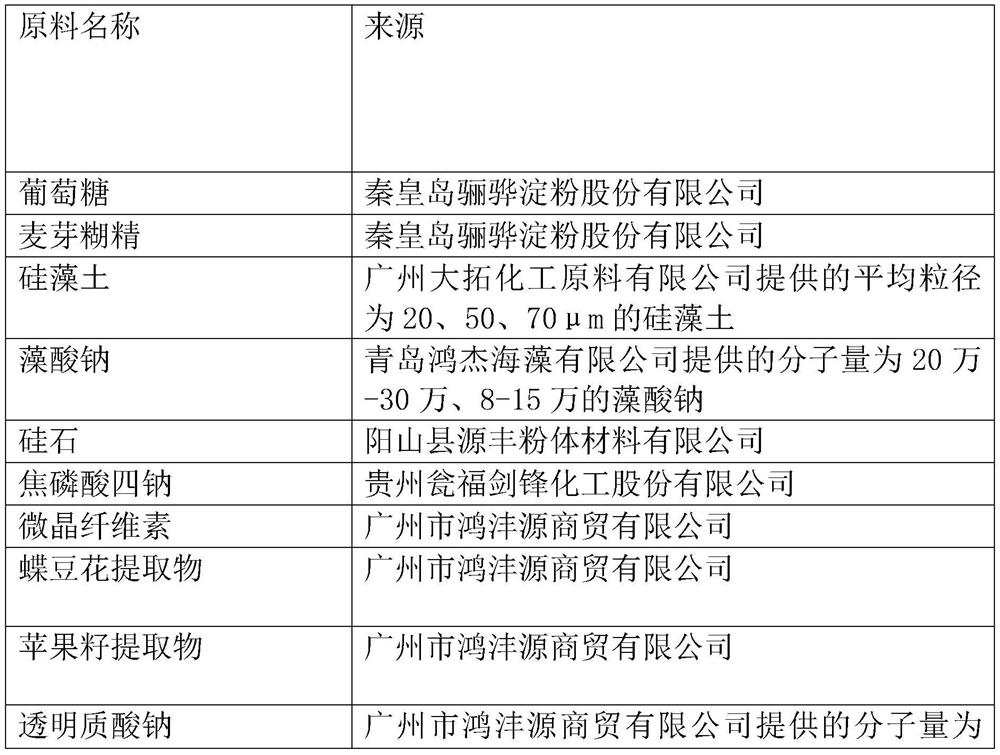

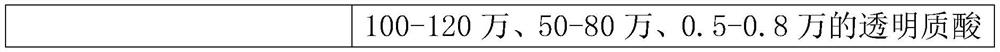

[0056] Embodiments 1-4 disclose a multifunctional microcrystalline soft film powder, which is prepared from the following components.

[0057] Bulking agent, sodium hyaluronate, diatomaceous earth, microcrystalline cellulose, butterfly pea flower extract, apple seed extract, sodium alginate, dispersing agent.

[0058] The filler is glucose, the dispersant is silica, the molecular weight of sodium alginate is 200,000-300,000, the molecular weight of sodium hyaluronate is 1 million-1.2 million, and the average particle size of diatomite is 70 μm. The specific input amount is shown in Table 2. Unit: Kg.

[0059] Table 2

[0060] Example 1 Example 2 Example 3 Example 4 glucose 30 38 42 50 Sodium hyaluronate 0.05 0.1 0.12 0.2 diatomite 10 18 22 30 microcrystalline cellulose 0.5 1 1.2 2 Butterfly Pea Flower Extract 0.2 0.6 0.8 1.5 Apple Seed Extract 0.1 0.4 0.6 1 sodium alginate 3 5.4 6.4 10 Silica...

Embodiment 5

[0064] The difference with Example 2 is only: 4Kg calcium sulfate and 0.5Kg tetrasodium pyrophosphate are also added in the stirring pot.

Embodiment 6

[0066] The difference with Example 2 is only: 10Kg calcium sulfate and 1.5Kg tetrasodium pyrophosphate are also added in the stirring pot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com