Front-thick deep-ploughing and rear-shallow-fine-crushing walking type rotary cultivator

A walk-behind and rotary tiller technology, which is applied to the chassis of agricultural machinery, agricultural machinery and implements, non-rotating vibration suppression, etc., can solve problems such as low work efficiency, large vibration, and land leveling, and achieve improved results and The effect of improving efficiency, improving service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

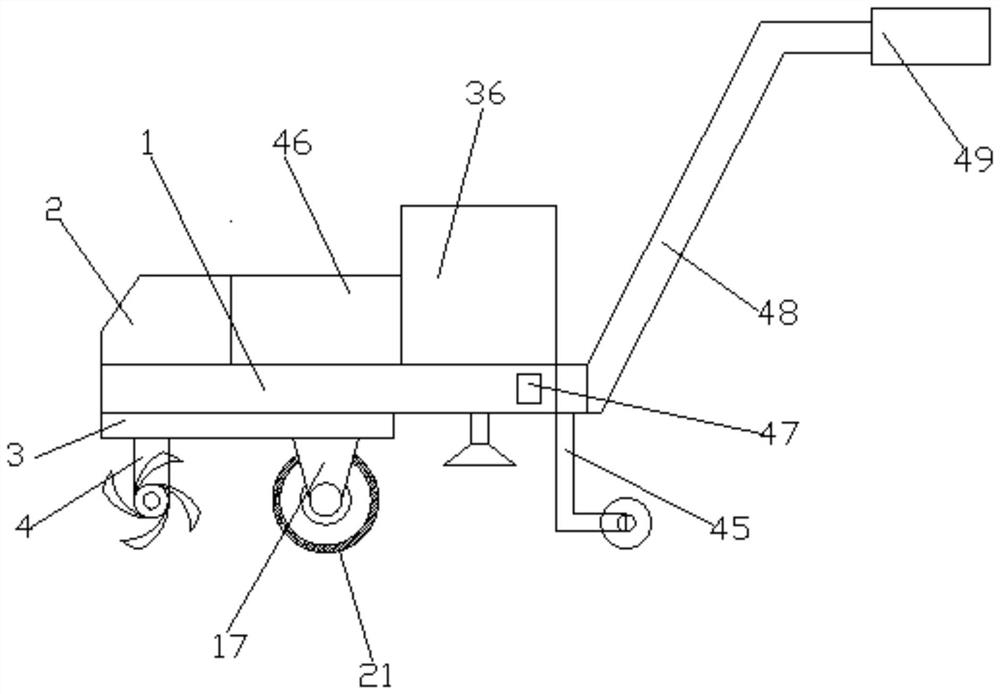

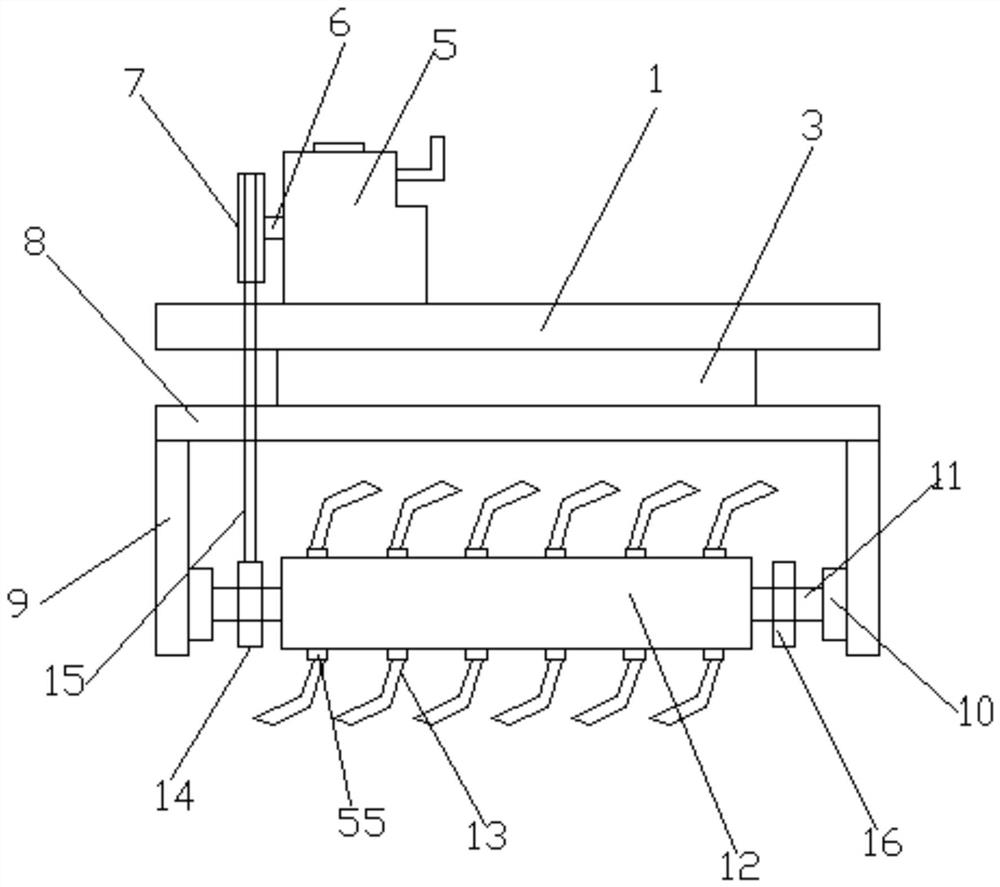

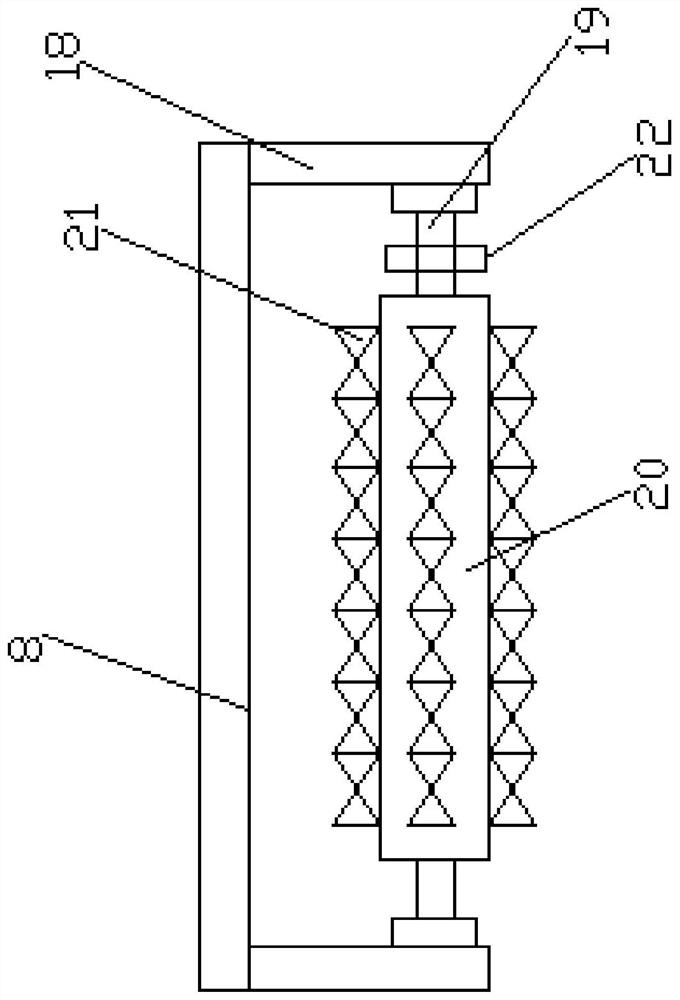

[0038] see Figure 1-8 , according to an embodiment of the present invention, a walk-behind rotary cultivator for coarse and deep plowing followed by shallow and fine crushing includes a fixed base 1, a driving device 2 is provided on the fixed base 1, and a shock-absorbing buffer is provided under the fixed base 1 Structure 3, a front deep plowing structure 4 is provided below the shock-absorbing buffer structure 3, the front deep plowing structure 4 is connected to the drive device 2, and the front deep plowing structure 4 includes a diesel drive on the front deep plowing structure 4 engine 5, the output end of the diesel driver 5 is connected with a transmission rod 6, one end of the transmission rod 6 is connected with a first pulley 7, and the bottom of the shock absorbing buffer structure 3 is connected with a connection base plate 8, and the connection Both sides below the bottom plate 8 are fixed with fixed side plates 9, and the inner side of the fixed side plate 9 is...

Embodiment 2

[0041] like figure 1 As shown, the fixed base 1 is provided with a fuel tank 46, and the fuel tank 46 is connected to the diesel driver 5, so as to improve the stability of the diesel driver 5 and prevent insufficient fuel.

Embodiment 3

[0043] like figure 1 As shown, the fixed base 1 is provided with a hand-held push rod 48, and the hand-held push rod 48 is provided with a rubber protective cover 49, which is convenient for pushing and using the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com