No-drilling-dirt base plate composite device for high-precision positioning electronic circuit board

A technology of electronic circuit boards and composite devices, which is applied in the direction of printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as burns on circuit boards, limited processing efficiency of composite devices, and affect device processing efficiency, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

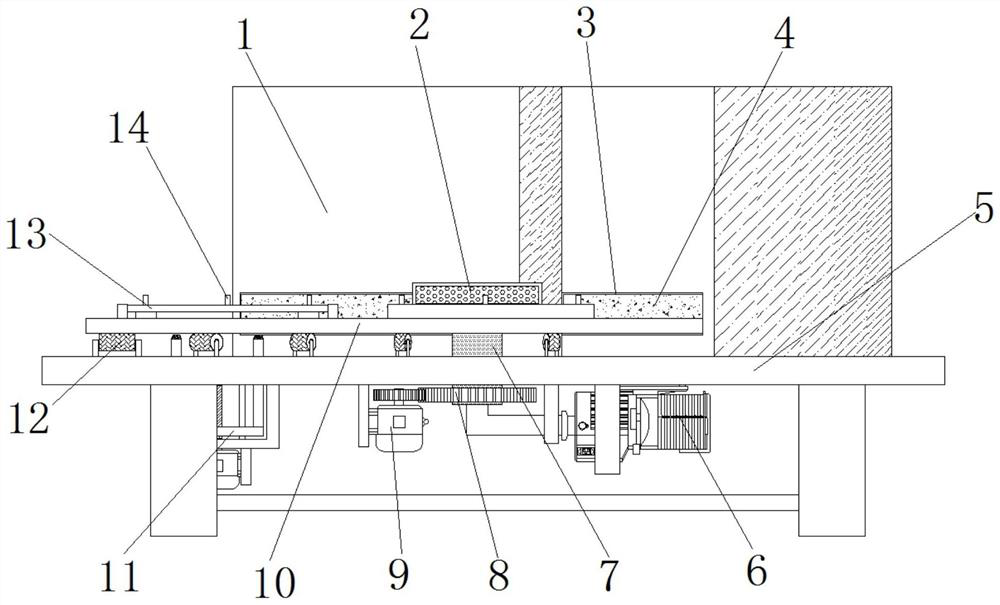

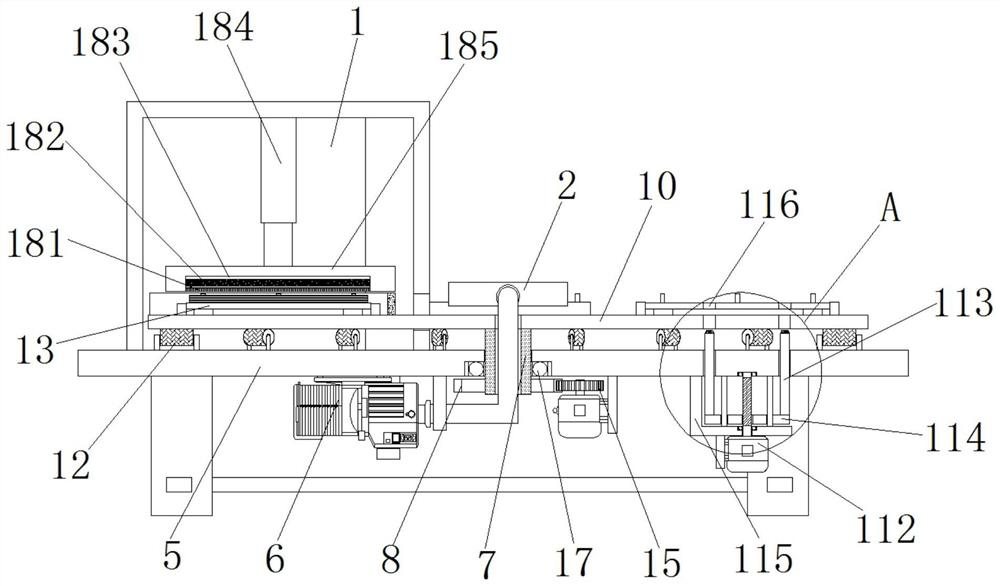

[0042] Example 1, such as Figure 1-6 As shown, when processing circuit boards, multiple groups of circuit boards and non-drilled backing plates are stacked on top of the placement board 13 in sequence, and the four sets of limit pins 14 on the top of the placement board 13 are inserted into the corresponding boards. In the limit hole on the top, so that the circuit boards are stacked orderly and neatly on the top of the placement plate 13, and then the first servo motor 9 is controlled to rotate one circle through the control panel 19, and the first servo motor 9 only rotates once at a time. circle, so that the rotating tube 7 and the turntable 10 rotate 90° clockwise, so that the circuit boards that have just been stacked are moved to the right below the second mounting seat 186, and the stacked circuit boards are moved to the first mounting seat 185. When directly below, control two groups of electric elevating rods 184 to elongate, let the bottom of the second mounting bas...

Embodiment 2

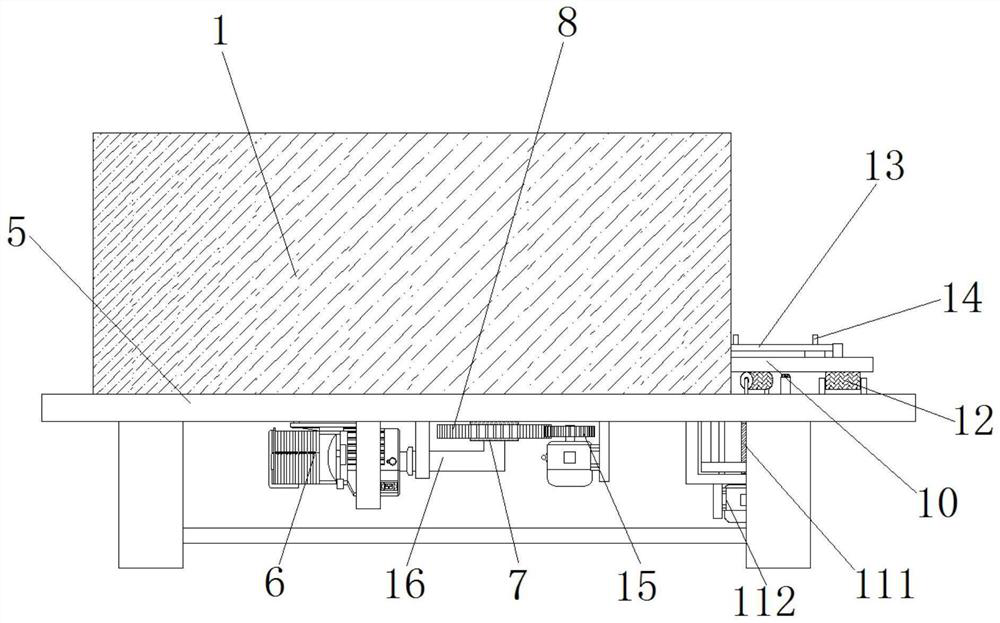

[0043] Example 2, such as figure 1 , 2 , 3, 4, 5 and 7, when the processed circuit board needs to be removed, the second servo motor 112 is controlled to rotate clockwise, and the lifting plate 114 is forced to rise gradually due to the external thread of the threaded rod 111. The four sets of ejector pins 113 are raised, and the ejector pins 113 pass through the through holes 116 on the turntable 10 and the placement plate 13 to lift the circuit boards on the placement board 13, so that the operator removes the circuit boards that have been fused, and The second servo motor 112 is controlled to rotate counterclockwise, so that the four sets of push rods 113 descend to their original positions.

[0044] Working principle: Connect the device to the power supply before use, first stack multiple sets of circuit boards and non-drilling backing boards on the top of the placement board 13 in sequence, and insert the four sets of limit pins 14 on the top of the placement board 13 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com