Insulator assembly and high-voltage switch equipment using insulator assembly

A technology of insulators and components, which is applied in the field of insulator components and high-voltage switchgear, and can solve problems such as unstable induced voltage signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

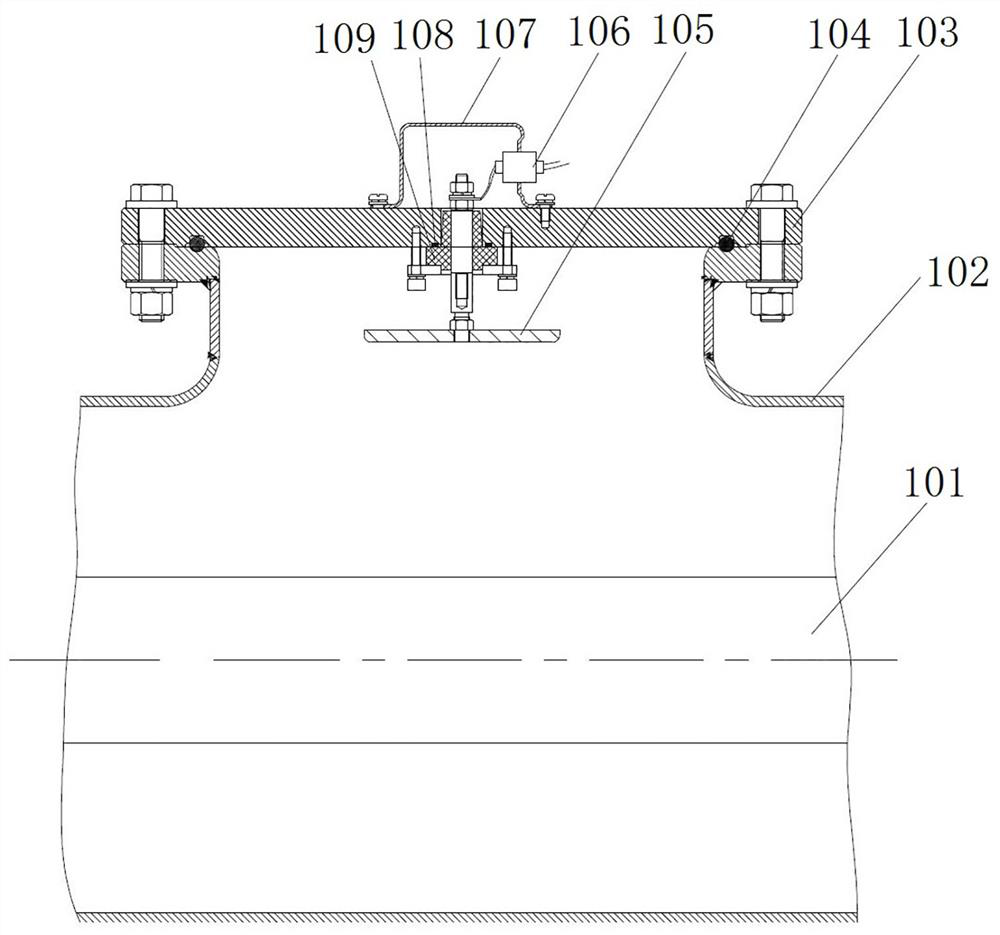

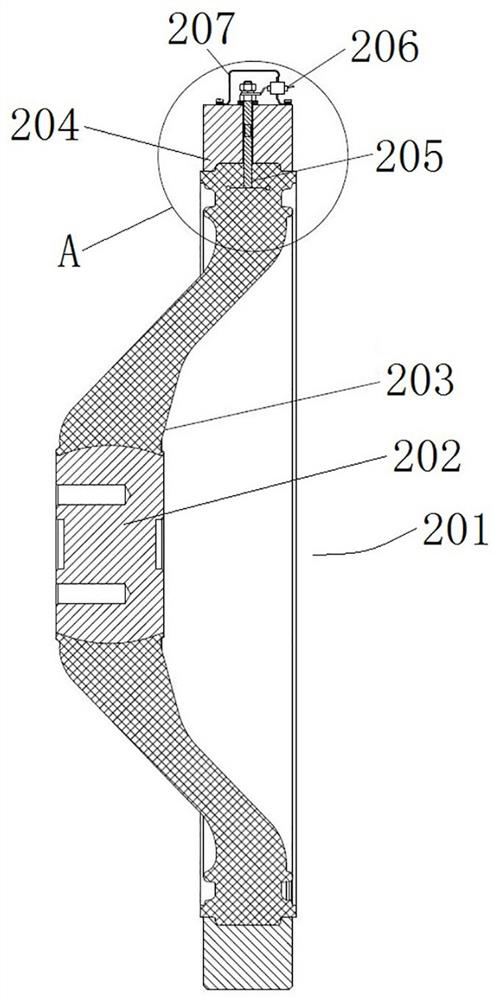

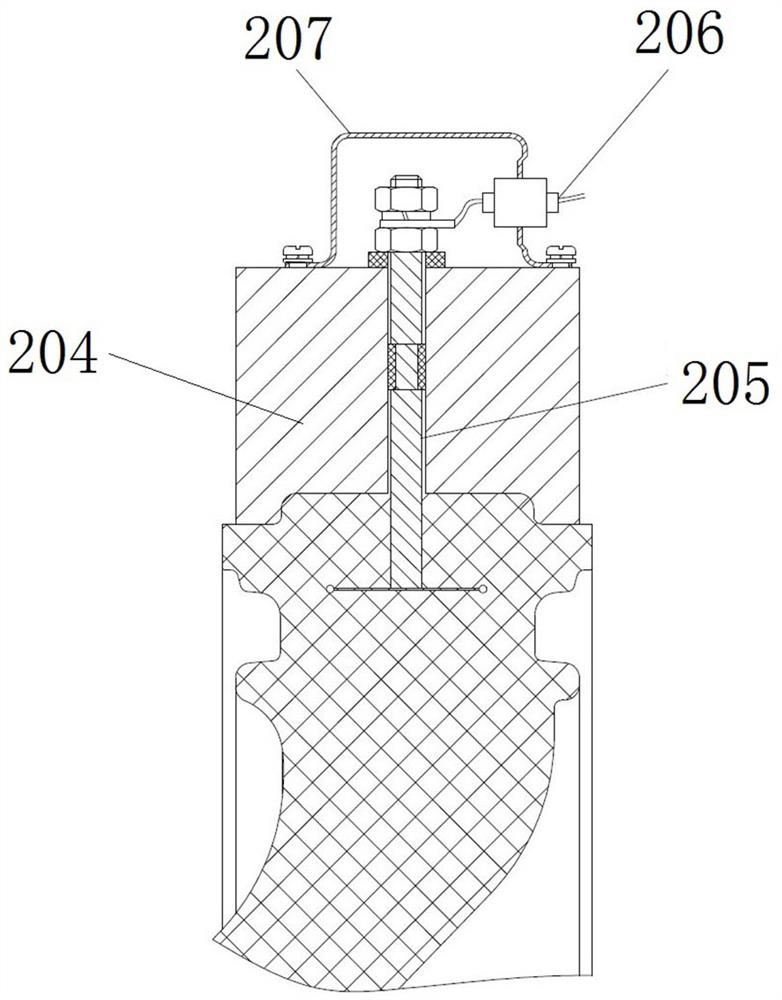

[0066]Such asFigure 4 to 6As shown, the insulator assembly includes an insulator 301, a sensor, a T-shaped joint 314, and a charging display device 316. The insulator 301 in the present embodiment is a basin insulator, including the intermediate main conductor 302, the edge metal flange 303, and the main conductor The insulating portion 304 between 302 and the metal flange 303 is formed, and the basin insulator is formed in a manner.

[0067]An electrode mounting hole is opened on the outer peripheral surface of the metal flange 303, and the electrode mounting hole extends along the radial direction of the insulator 301, and the electrode mounting hole extends into the insulating portion 304, the electrode mounting hole is used to mount the sensor, the hole of the electrode mounting hole. For sphere. The electrode mounting holes here include two parts, and a portion is located in the insulating portion 304, and the other portion is opened in the metal flange 303, wherein the portion lo...

Embodiment 1

[0077]In Example 1, there was a pin on the T-shaped joint, and the wiring portion on the electrode was an elastic jug. In the present embodiment, the wiring portion on the electrode is a pin, and an elastic jug on the T-shaped joint is also achieved, and the T-shaped joint is connected to the electrode.

[0078]When actually designed and processed, the shape of the joint can be changed.

[0079]Alternatively, the wiring portion on the electrode is a threaded hole opened on the electrode, and the outer shield cable is secured to the electrode by a DT joint.

specific Embodiment 3

[0081]In Example 1, between the cover plate and the metal flange, there was a seal between the electrodes and the electrode mounting hole wall. In this embodiment, only one seal is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com