Method for improving performance of AlCrN coating cutter through in-situ high-energy Ar < + > etching aftertreatment

A coating, high-energy technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of reducing the overall performance of the coating, increasing the friction resistance, increasing the surface roughness of the coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

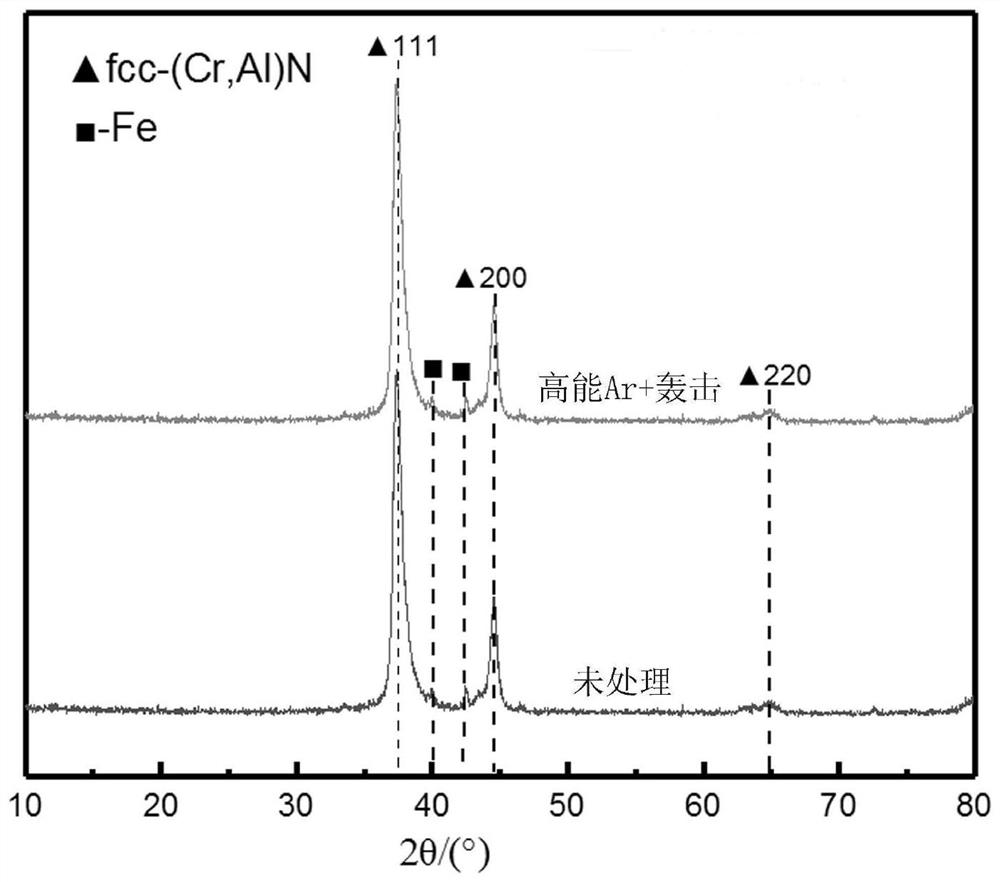

[0044] M42 high-speed steel specimens and M42 high-speed steel straight shank end mills with a diameter of 10 mm were selected for the test. The test uses two symmetrically distributed AlCr (atomic ratio Al:Cr=70:30, purity 99.5%) alloy targets. Before coating, use high-energy Ar + Bombarding the surface of the substrate, that is, etching and cleaning the surface of the substrate, the current is 90A, the time is 30min; when coating, the temperature is 450℃, N 2 Pressure 4.0*10 -2 The mbar and AlCr alloy target currents are all 130A, and the deposition time is 2 hours.

[0045]The prepared AlCrN coating was tested.

Embodiment 2

[0047] The preparation method of the AlCrN coating is the same as that of the first embodiment.

[0048] The prepared AlCrN coating is subjected to post-treatment again, and the post-treatment steps of in-situ high-energy Ar ion bombardment are as follows:

[0049] In the first step, the vacuum degree in the furnace reaches 2.0x10 -4 At Pa, Ar gas with a purity of 99.999% was introduced and heated to 400°C; in the second step, a cylindrical Ti target was turned on as a traction arc target, and the current during cleaning was controlled to 80A, which excited a large number of electrons. Turn on the circular auxiliary anode target, and form the positive and negative electrode traction electron movement with the Ti target. Electrons collide with Ar gas in the furnace to generate high-density Ar + . The negative bias of the substrate is -200V, attracting Ar + Carry out ion bombardment on the surface of the substrate; in the third step, the bombardment time is 40min.

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com