UTG glass ceramic plate tempered frame

A glass-ceramic and ceramic technology, applied in the field of UTG glass-ceramic plate tempering frame, can solve problems such as edge chipping, touch screen glass fragments, falling into the tempering furnace, etc., to reduce surface pits and avoid mutual contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

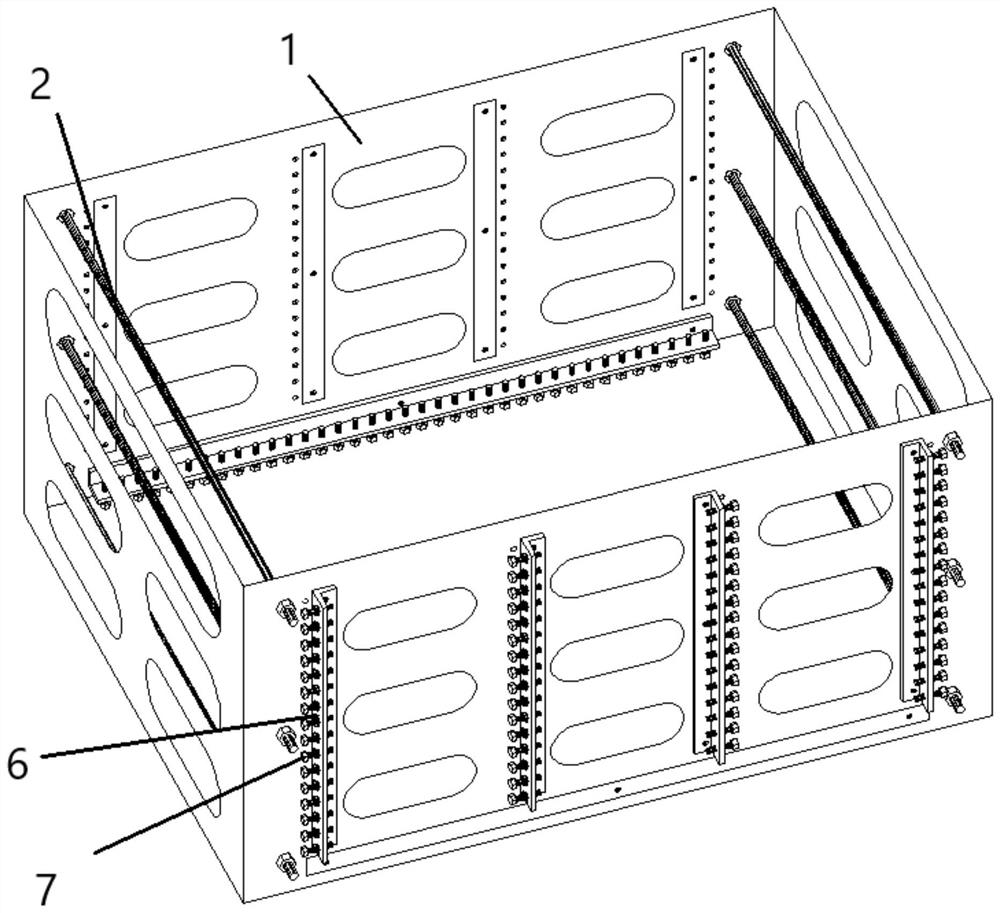

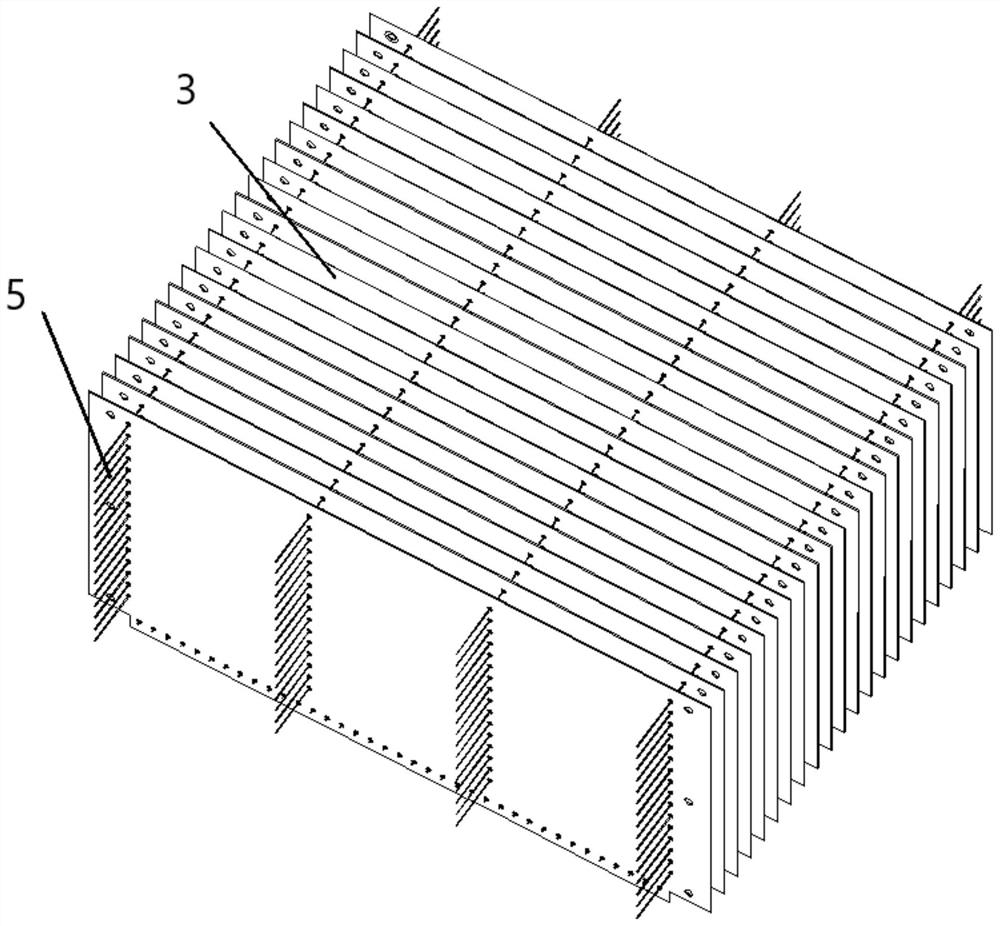

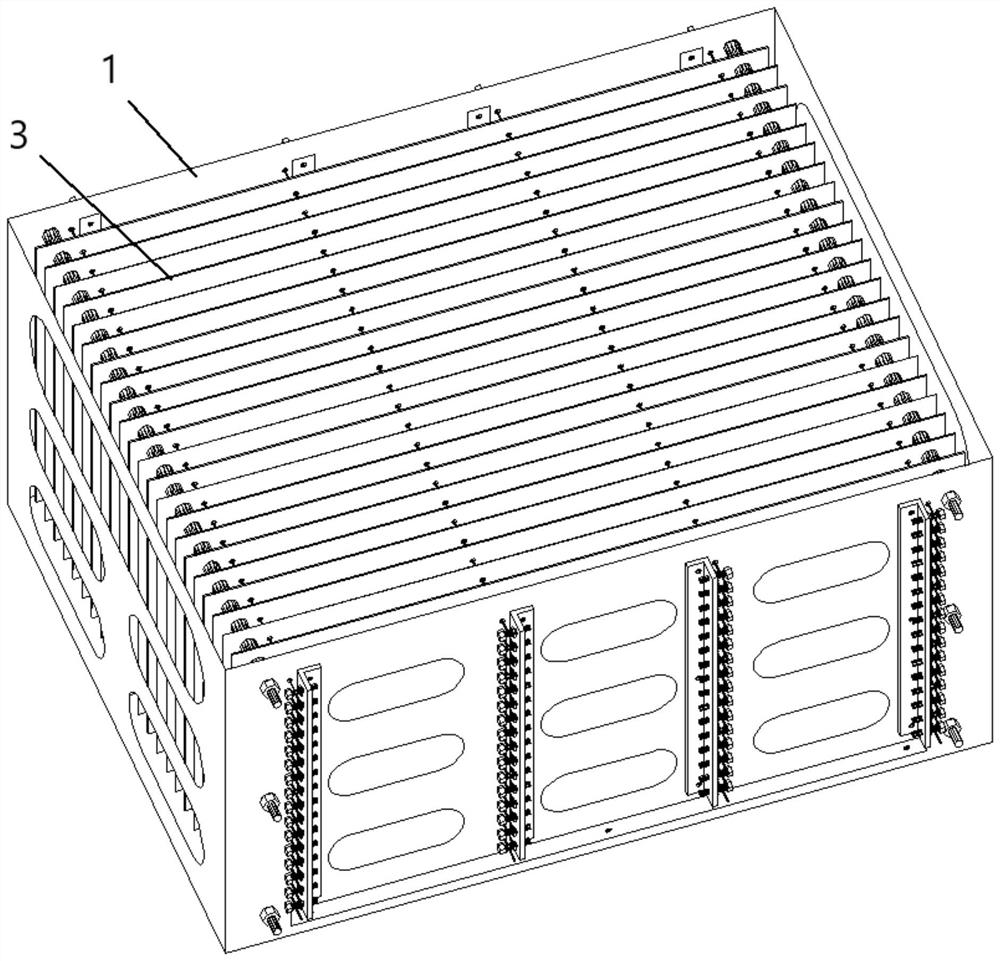

[0016] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of the outer frame body of a kind of UTG glass-ceramic plate tempered frame proposed by the present invention, figure 2 It is a structural schematic diagram of a ceramic partition of a UTG glass-ceramic plate tempered frame proposed by the present invention, image 3 It is a schematic diagram of the overall structure of a tempered frame of a UTG glass ceramic plate proposed by the present invention.

[0017] refer to Figures 1 to 3 , a kind of tempered frame of UTG glass-ceramic plate that the present invention proposes, comprises: outer frame body 1, a plurality of supporting rods 2, a plurality of ceramic separators 3;

[0018] A plurality of ceramic partitions 3 are arranged in the outer frame body 1 in parallel and at intervals in sequence, and a plurality of positioning holes respectively corresponding to the plurality of supporting links 2 are arranged on the ceramic partitions 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com