Electroplating apparatus

An electroplating device and electrode technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of reduced operating efficiency, electroplating adhesion, uneven thickness of electroplating film, damage to the inner peripheral surface of the cylinder, etc., to prevent damage and improve operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

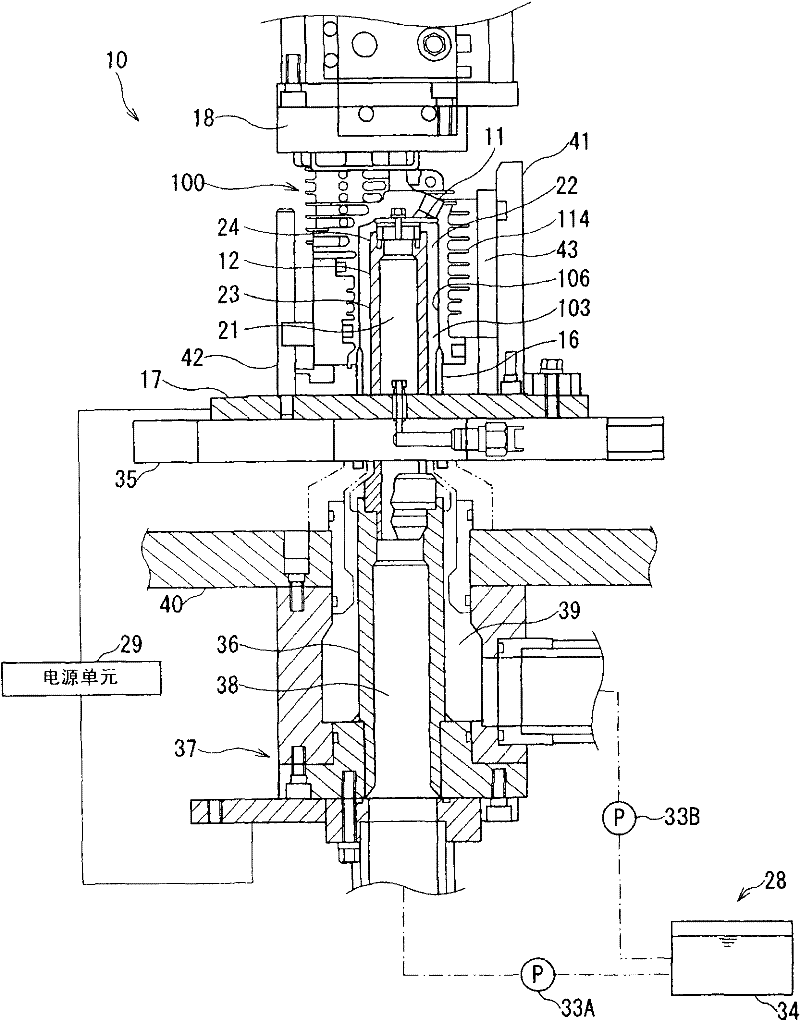

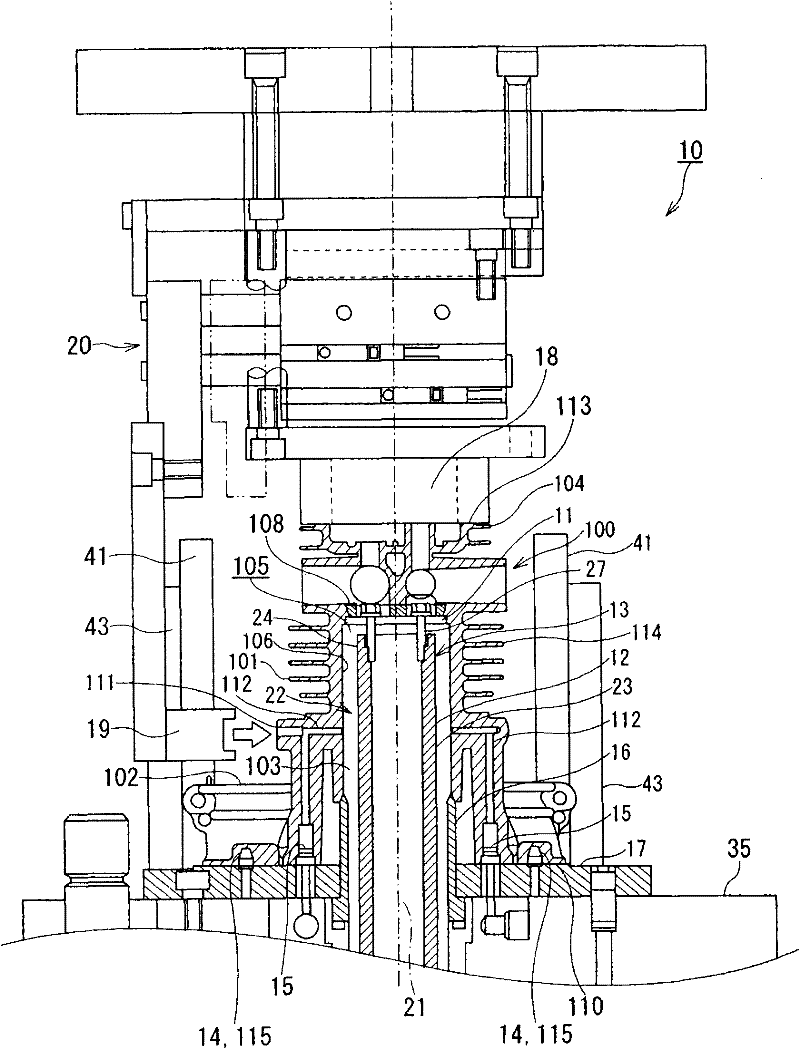

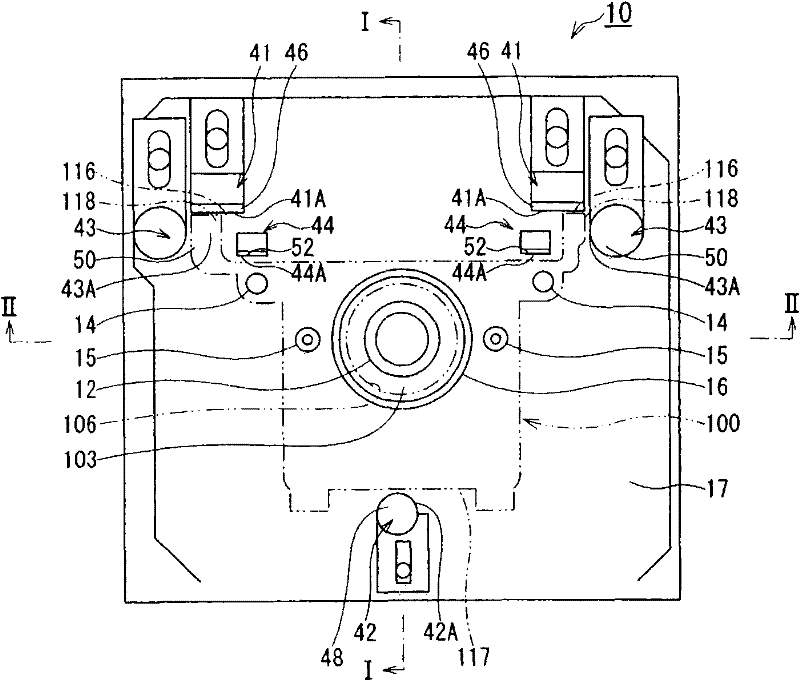

[0033] [The first embodiment ( Figure 1 to Figure 1 0)]

[0034] Figure 1 to Figure 3 The illustrated plating device 10 functions to forcibly introduce and flow a treatment solution (pre-plating solution or plating solution) to the cylinder inner peripheral surface 106 of the cylinder block 100 of the engine so that the cylindrical electrode 12 and the cylinder block 100 are energized A pre-plating process or a plating process is performed on the cylinder inner peripheral surface 106 at high speed.

[0035] For the above purpose, the electroplating apparatus 10 includes: an electrode unit 13 including a cylindrical electrode 12 and a first sealing member 11; a workpiece mounting platform 17 including a positioning pin 14; a connector pin 15 as a connecting member and a second sealing member 16 a work holding fixture (work holding fixture) 18; a closing unit 20 comprising a third sealing member 19; a processing liquid supply unit 28; a power supply unit 29; including an ins...

no. 2 example

[0102] [The second embodiment ( Figure 11 )]

[0103] Figure 11 With Figure 8 Correspondingly, a schematic side view of the main part of the second embodiment of the electroplating apparatus according to the present invention is shown. In the second embodiment, parts similar to those of the first embodiment are identified by the same reference numerals, and descriptions thereof are simplified or omitted.

[0104] The electroplating apparatus 60 of the second embodiment is different from the electroplating apparatus 10 in the first embodiment in that the insertion guide 61 includes a prism portion 62, a cylindrical portion 63 integrally provided at the top end of the prism portion 62, and a tapered portion 64. and 65 , tapered portions 64 and 65 tapered toward their respective pointed ends, are formed on the top ends of the prismatic portion 62 and the cylindrical portion 63, respectively.

[0105] The taper angle of the tapered portion 64 at the top end of the prism por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com