Method for manufacturing molten irons by injecting a hydrocarbon gas and apparatus for manufacturing molten irons using the same

A technology of molten iron and equipment, applied in lighting and heating equipment, reducing gas emissions, furnace components, etc., can solve problems such as serious environmental pollution, difficulty in furnace-gasifier activities, and failure to reduce iron ore to make contributions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] best practice

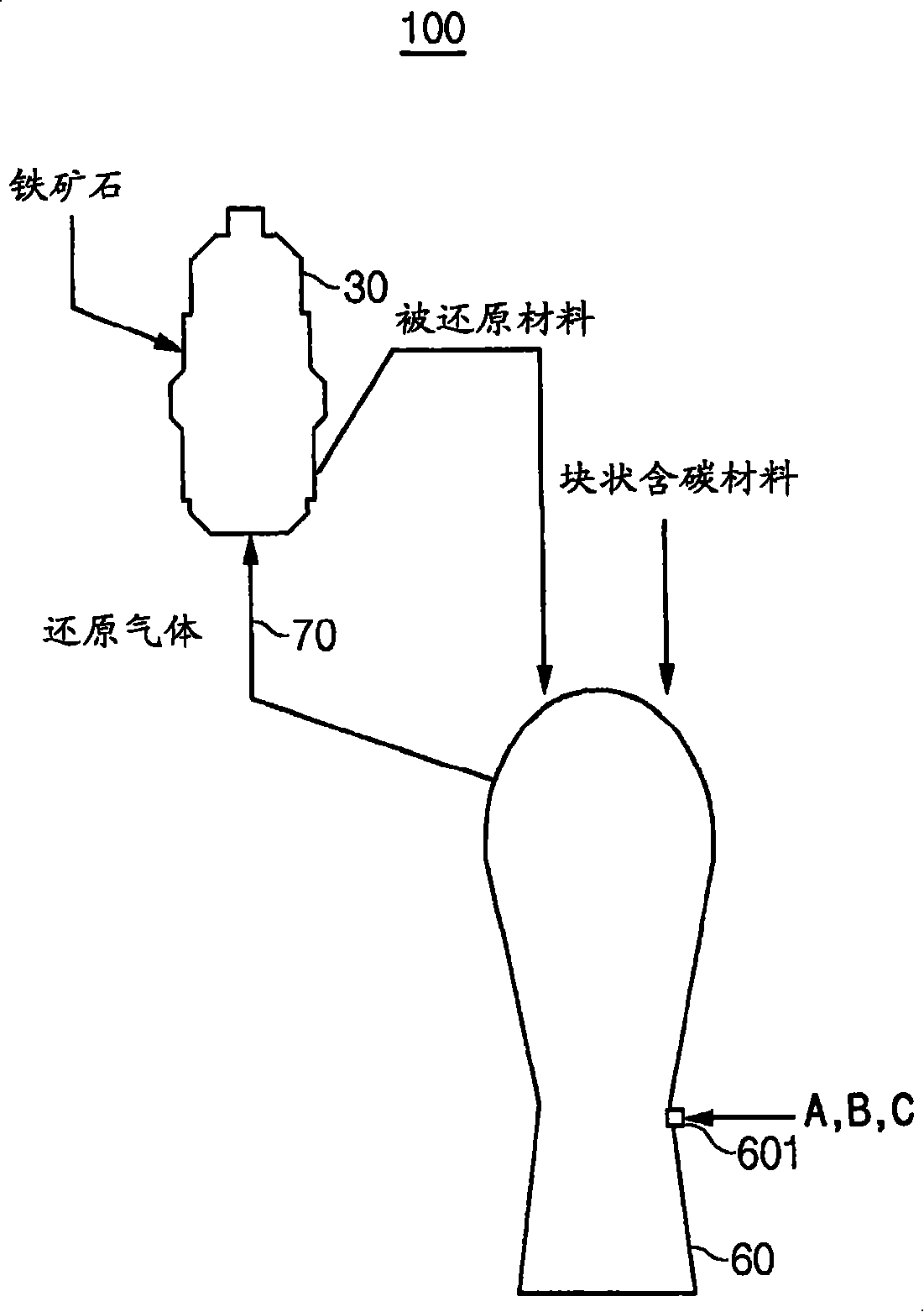

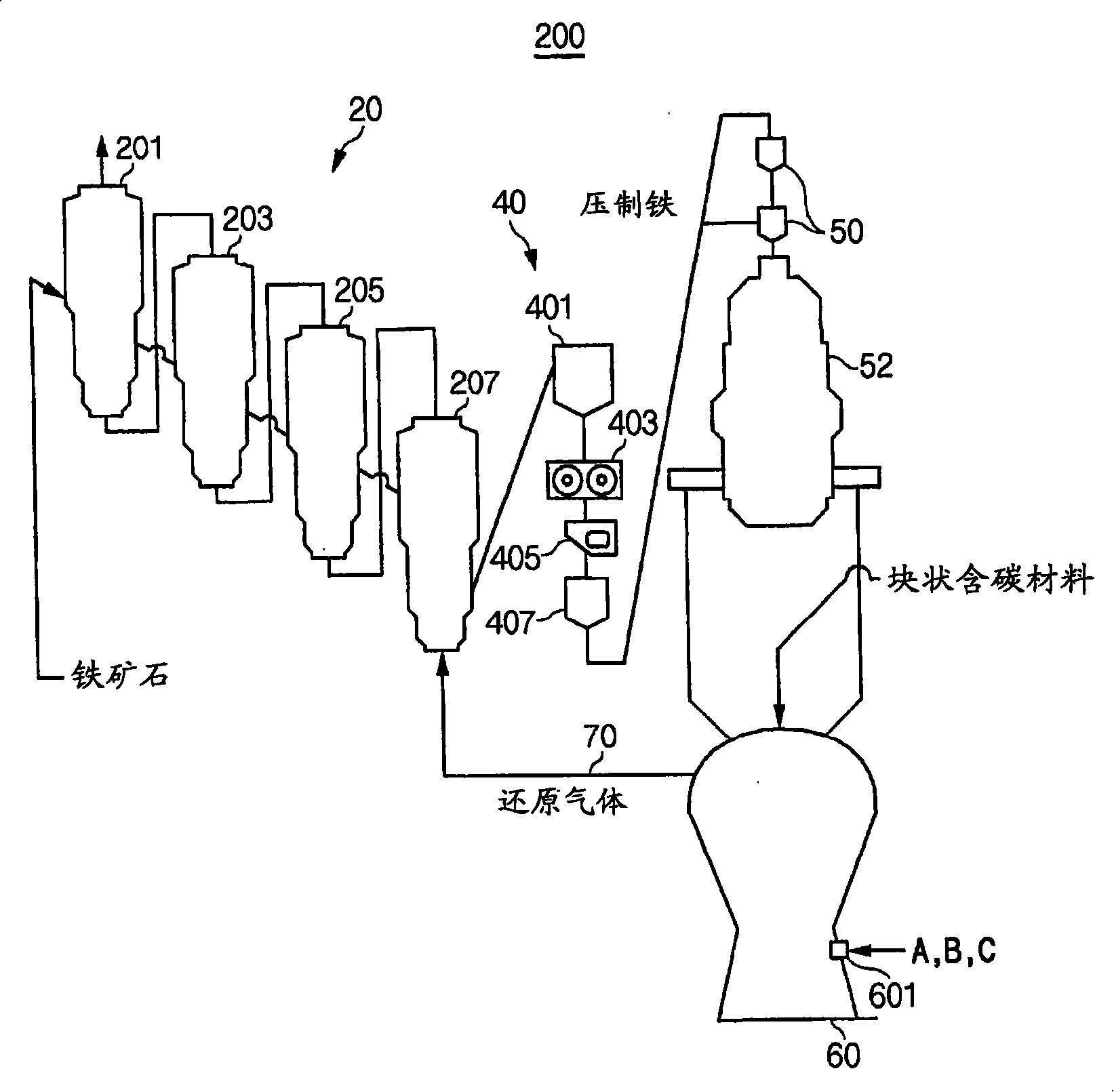

[0024] In order for those of ordinary skill in the art to be able to implement the present invention, reference will be made to Figures 1 to 4 Embodiments of the present invention will be described. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit and scope of the present invention. Wherever possible, the same reference numerals will be used throughout the drawings for the same or like parts.

[0025] Unless otherwise defined, all terms (including technical terms and scientific terms) used in this specification have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. It should be further understood that terms, such as terms defined in commonly used dictionaries, etc., should be interpreted to have meanings consistent with their meanings in the relevant art and within the scope of this disclosure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com