Manufacturing method and structure of touch module signal connecting end

A signal connection, touch module technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve problems such as no substrate layer, no solution for electrical connection of circuit boards, etc. Achieve the effect of preventing mutual contact and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

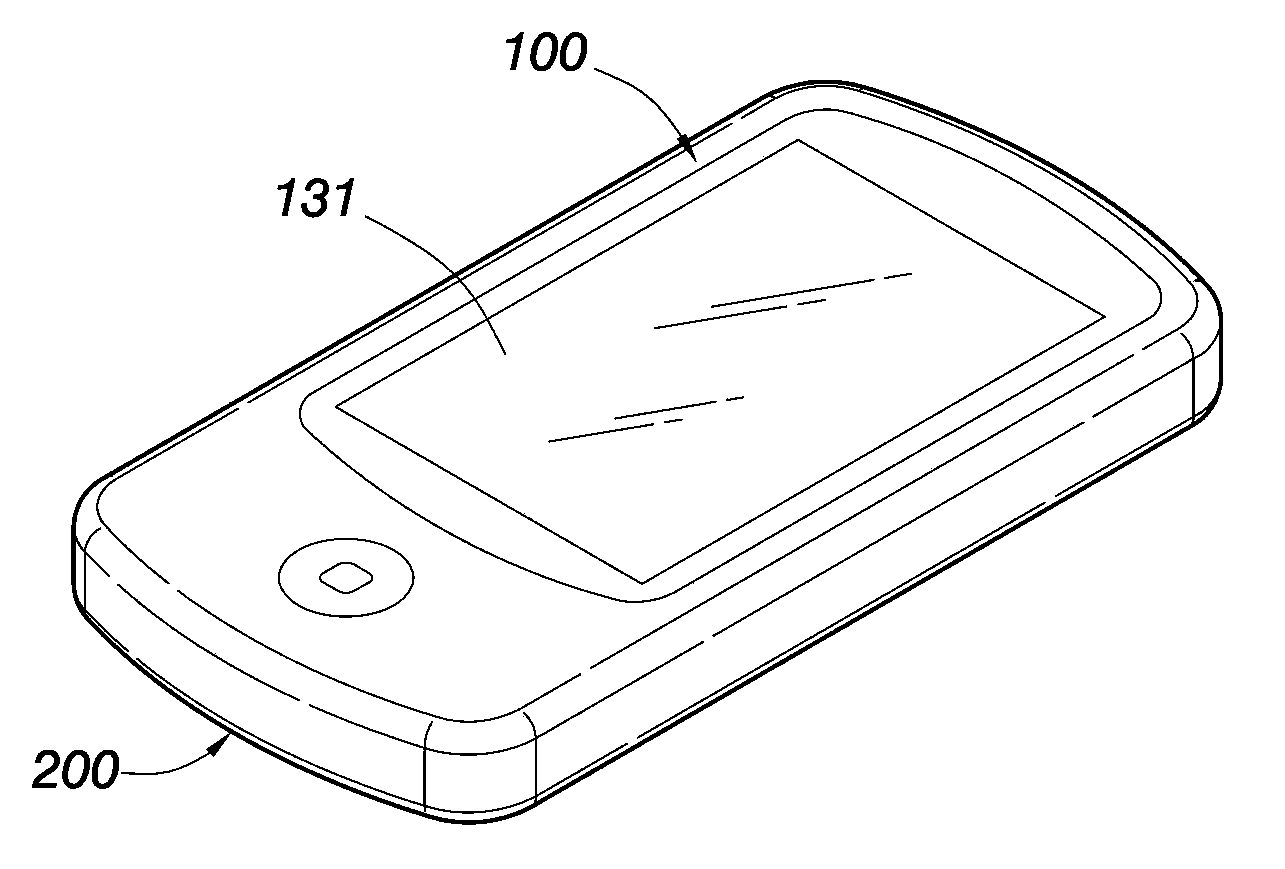

[0047] see figure 1 , revealing that the touch module 100 of the present invention can be arranged on an external electronic product 200 such as a mobile phone; in practice, there is a liquid crystal display ( LCD, not shown), the user can observe the information displayed on the liquid crystal display through the touch module 100 .

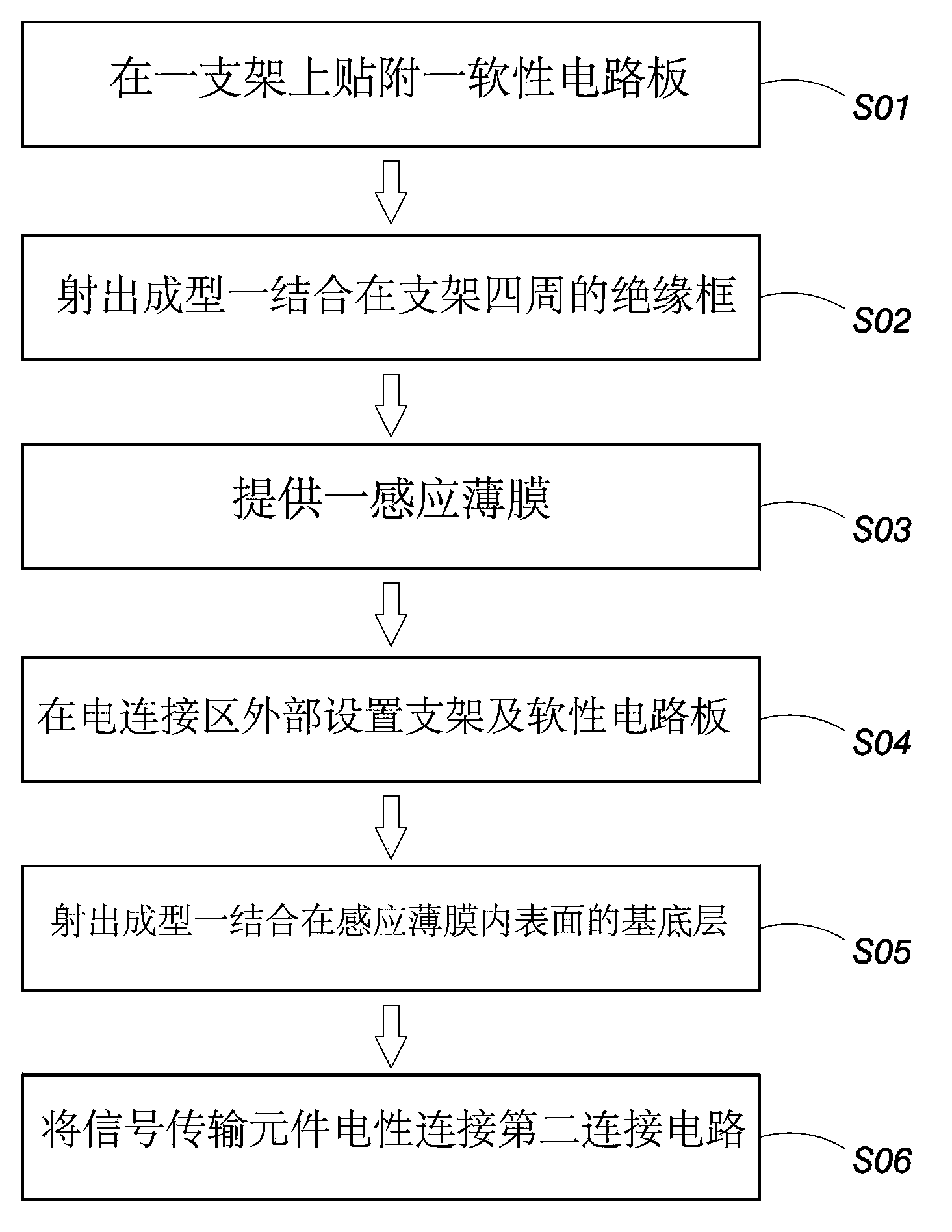

[0048] Please cooperate with the manufacturing method of the signal connection end of the touch module of the present invention Figure 2 to Figure 6 disclosed, comprising the following implementation steps:

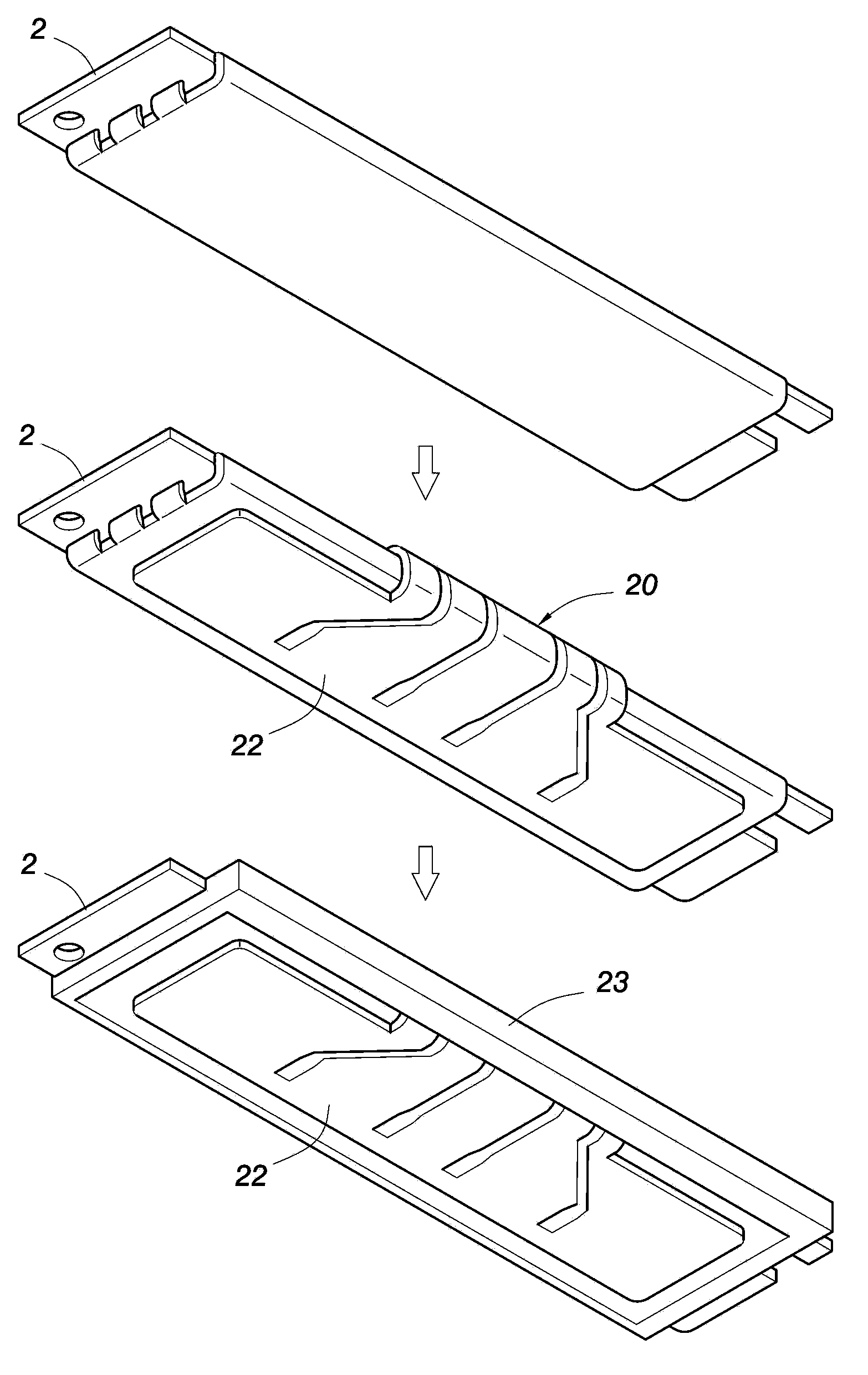

[0049] Step S01: Provide a bracket 2, the bracket 2 is in the shape of a straight plate, and the cross-section of the bracket 2 is ㄈ-shaped, and a flexible circuit board 20 is attached to the front and back sides of the bracket 2 in a curved manner. The board 20 has a first connection circuit 21 and a second connection circuit 22 which are connected to each other, so that the first and second connection circuits 21 and 22 of the flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com