Discharging mechanism of vanadium-nitrogen alloy machining equipment

A technology of processing equipment and unloading mechanism, applied in the field of vanadium-nitrogen alloy processing, can solve the problems of inconvenient unloading of staff, burns of grinding rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

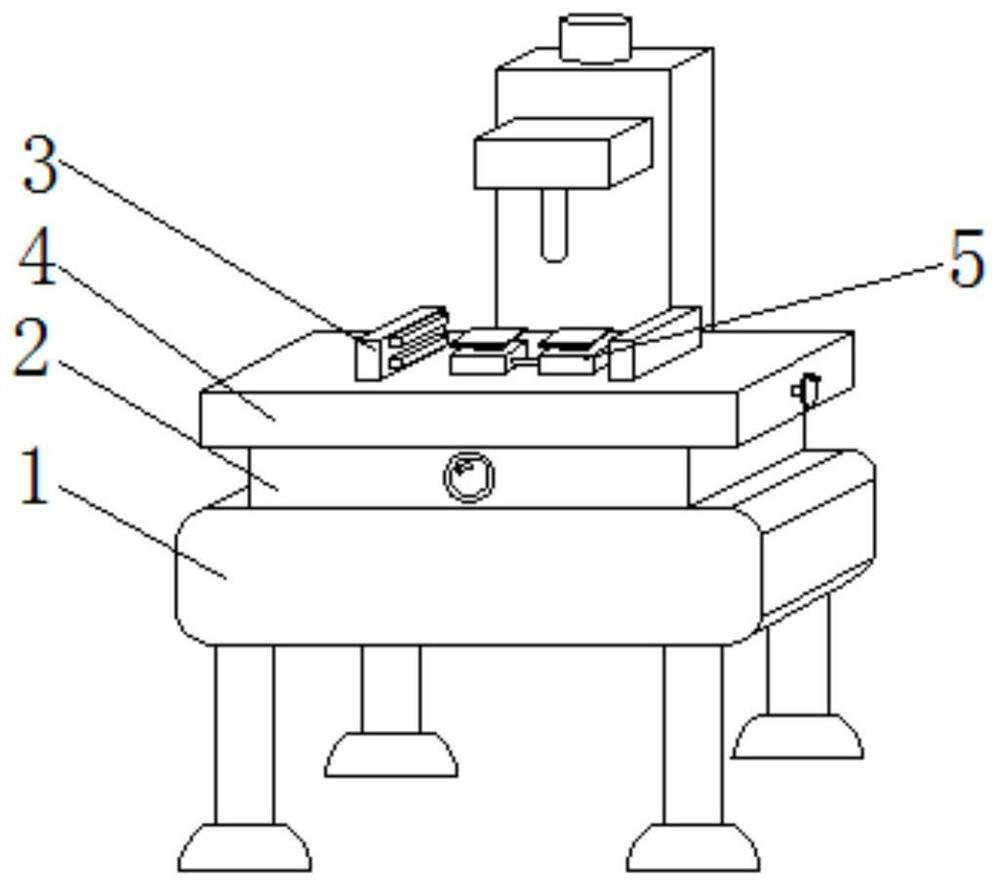

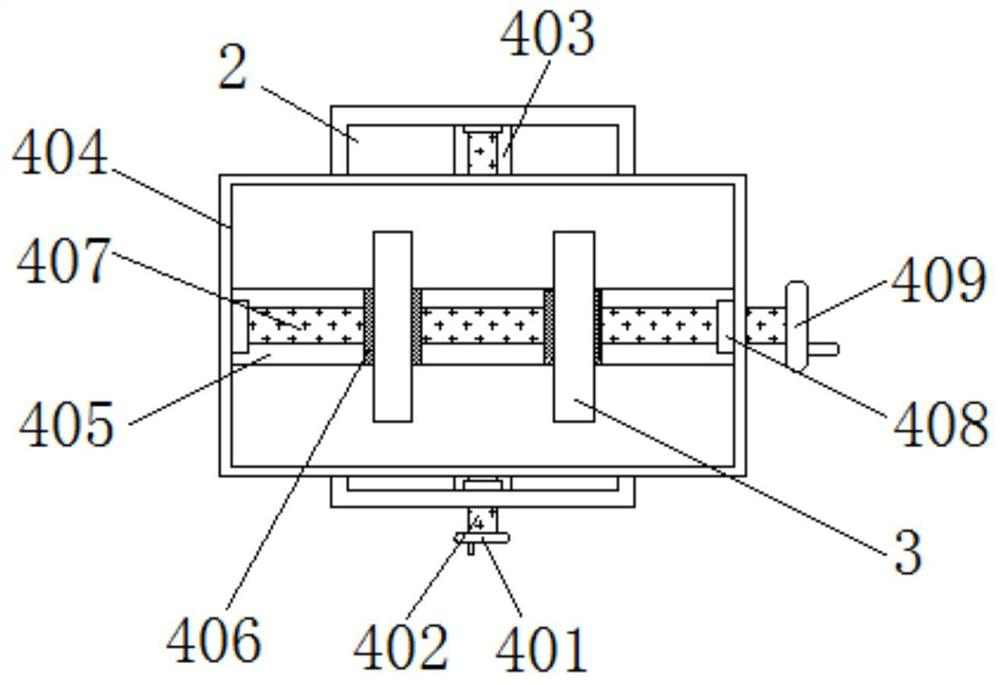

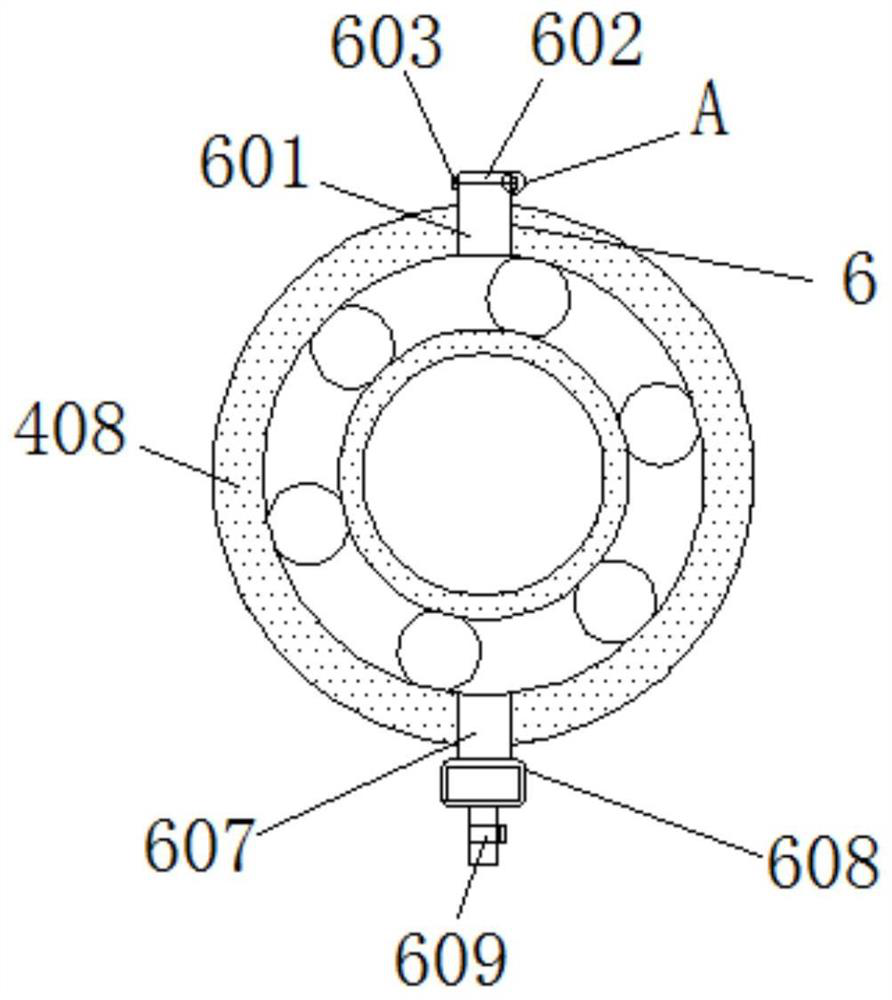

[0030] Such as Figure 1-Figure 7As shown, a unloading mechanism of a vanadium nitrogen alloy processing equipment includes a processing bed 1, a processing pedestal 2, a chuck 3, a discharge transposition mechanism 4, a first rotating wheel 401, a first transmission shaft 402, a first Guide groove 403, movable table 404, second guide groove 405, retaining block 406, second drive shaft 407, retaining bearing 408, second rotating wheel 409, unloading lowering mechanism 5, screw head 501, third drive shaft 502, retaining collar 503, turbine 504, worm 505, anti-off plate 506, movable plate 507, support platform 508, first slider 509, first chute 510, mounting seat 511,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com