System, method and reaction device for process for preparing trifluoroethane through continuous reaction

A reaction device, the technology of trifluoroethane, applied in the field of chemical engineering, can solve the problems of affecting the main reaction, affecting the utilization rate of raw materials, self-polymerization side reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

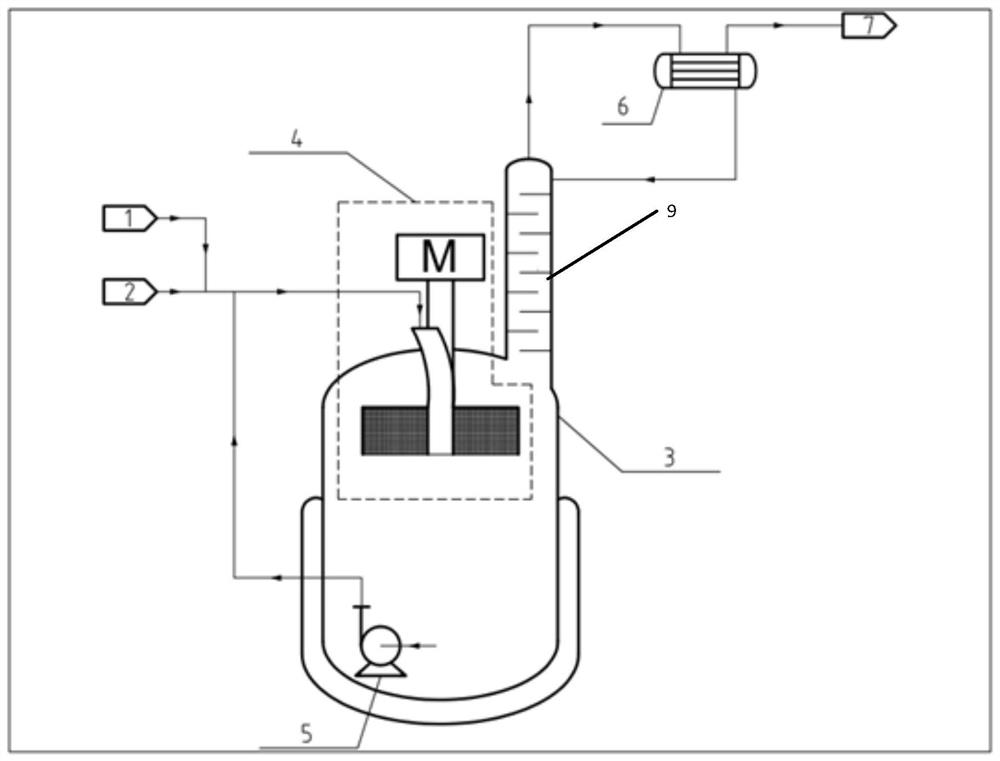

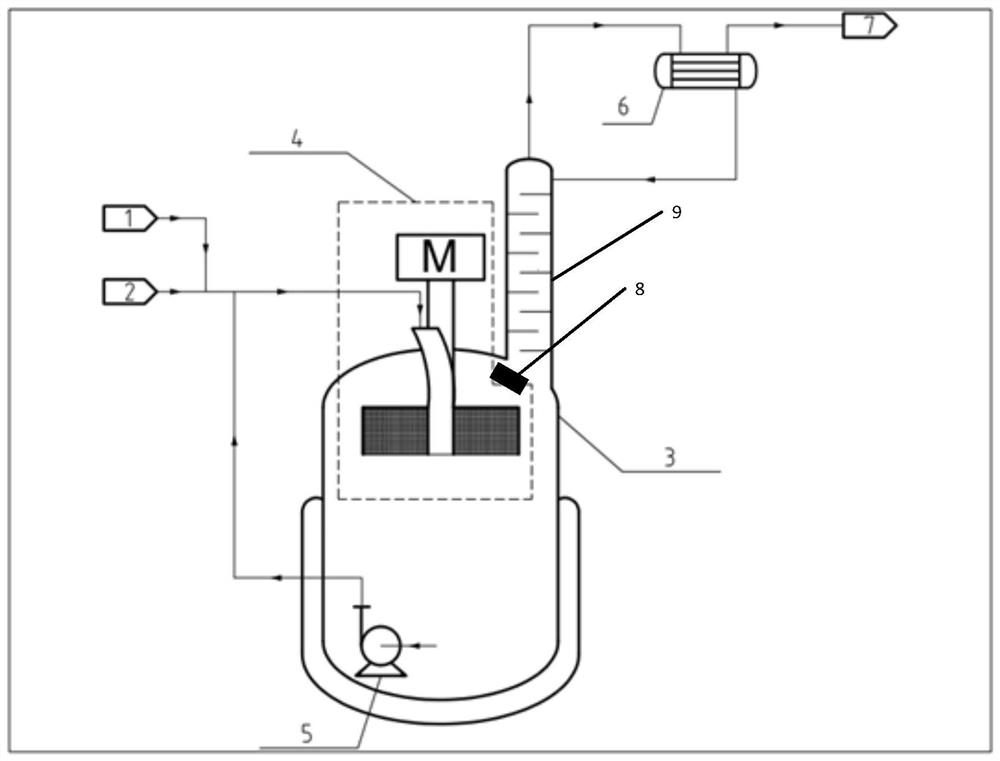

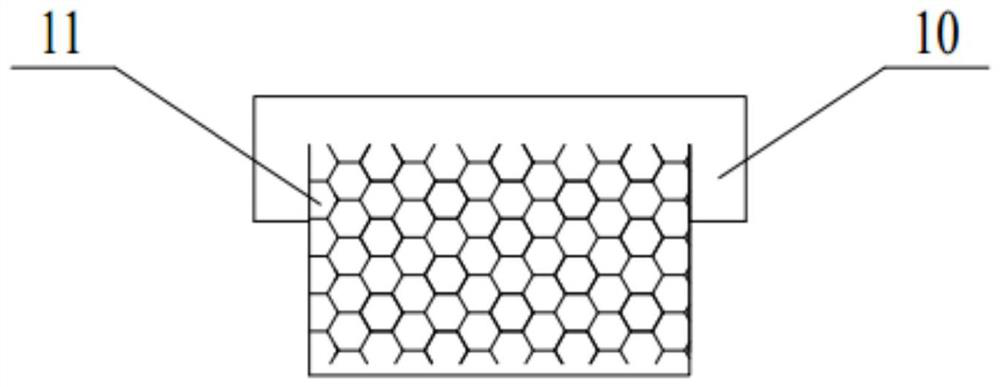

Method used

Image

Examples

Embodiment 1

[0096] Adopt device and method of the present invention to prepare 1,1,1-trifluoroethane (HFC-143a) by continuous reaction, adopt SnCl Catalyst, the molar ratio of catalyst molecule and the vinylidene chloride substance of fresh feed is 0.2:1 wherein hydrogen fluoride and 1,1,1-trifluoroethane (HFC-143a) feed molar flow ratio is 3:1, the reaction temperature is 85 ℃, the system pressure is maintained at 1.2MPa, the supergravity level of the built-in supergravity reactor is 500g, the circulation ratio is 8:1. It was measured that the conversion rate of vinylidene chloride was 99.3%, and the mass fraction of HFC-143a (without hydrogen chloride) in the outlet gas was 99.8%.

Embodiment 2

[0098] Adopt device and method of the present invention to prepare 1,1,1-trifluoroethane (HFC-143a) by continuous reaction, adopt SnCl Catalyst, the molar ratio of catalyst molecule and the vinylidene chloride substance of fresh feed is 0.2:1 wherein hydrogen fluoride and 1,1,1-trifluoroethane (HFC-143a) feed molar flow ratio is 4:1, the reaction temperature is 85 ° C, the system pressure is maintained at 1.2MPa, the supergravity level of the built-in supergravity reactor is 600g, the circulation ratio is 10:1. It was measured that the conversion rate of vinylidene chloride was 99.8%, and the mass fraction of HFC-143a (without hydrogen chloride) in the outlet gas was 99.9%.

Embodiment 3

[0100] Adopt device and method of the present invention to prepare 1,1,1-trifluoroethane (HFC-143a) by continuous reaction, adopt SnCl Catalyst, the molar ratio of catalyst molecule and the vinylidene chloride substance of fresh feed is 0.2:1 wherein hydrogen fluoride and 1,1,1-trifluoroethane (HFC-143a) feed molar flow ratio is 3:1, the reaction temperature is 80 ℃, the system pressure is maintained at 1.2MPa, the supergravity level of the built-in supergravity reactor is 300g, the circulation ratio is 8:1. It was measured that the conversion rate of vinylidene chloride was 98.9%, and the mass fraction of HFC-143a (without hydrogen chloride) in the outlet gas was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com