Method for measuring spin seebeck coefficient of magnetic nanowire

A technology of spin Seebeck and magnetic nano, which is applied in the field of measurement and sensing, and can solve problems such as limited temperature difference and increased complexity of magnetic nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

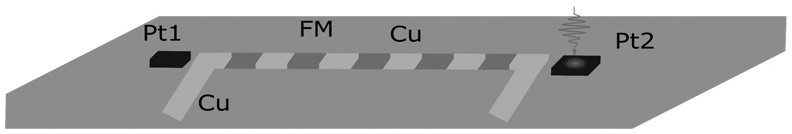

[0015] Example 1: A method of measuring magnetic nanowire spin Seebeck coefficient to measure magnetic nanowire [Co / Cu / Co] 100 Take the spin Seebeck coefficient as an example, the width of the magnetic nanowire is 500 nm, the length is 1.2 μm, the size of the platinum electrode films Pt1 and Pt2 at both ends is 10 μm×10 μm, and the distance between the platinum electrode and the magnetic nanowire is 15 nm, Magnetic nanowires and platinum electrodes are located on SiO 2 On the substrate, the whole sample as figure 1 As shown, the measurement process of its spin Seebeck coefficient includes the following steps:

[0016] (1): Platinum electrode temperature sensor calibration: place the magnetic nanowire on the heating resistance heating platform. The resistance heating wire is tungsten wire with a diameter of 2 mm. The resistance temperature measuring device used is Pt100. The resistance heating platform can reach The temperature is 100 o C, using the resistance of Keithley 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com