Compressor and refrigeration equipment

A technology of compressors and bearings, which is applied in the field of refrigeration equipment and can solve problems such as poor oil separation effect of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]It should be noted that the description of "first", "second", etc., "first", "second", etc., as described in the embodiment of the present invention, is only used to describe purposes, and cannot be understood as an indication or Imprepect its relative importance or implicitly indicated the number of technical features indicated. Thus, features with "first", "second" may be indicated or implicitly including at least one of this feature. In addition, the meaning of "and / or" in full text is, including three parallel schemes, as examples "a and / or b", including A schemes, or B regions, or A and B satisfying options.

[0043]The present invention proposes a compressor. The compressor specifically involves a rotary compressor, but is not limited thereto. Specifically, the compressor can be a single cylinder single-row compressor, a single cylinder double row compressor, a dual cylinder compressor, and the like.

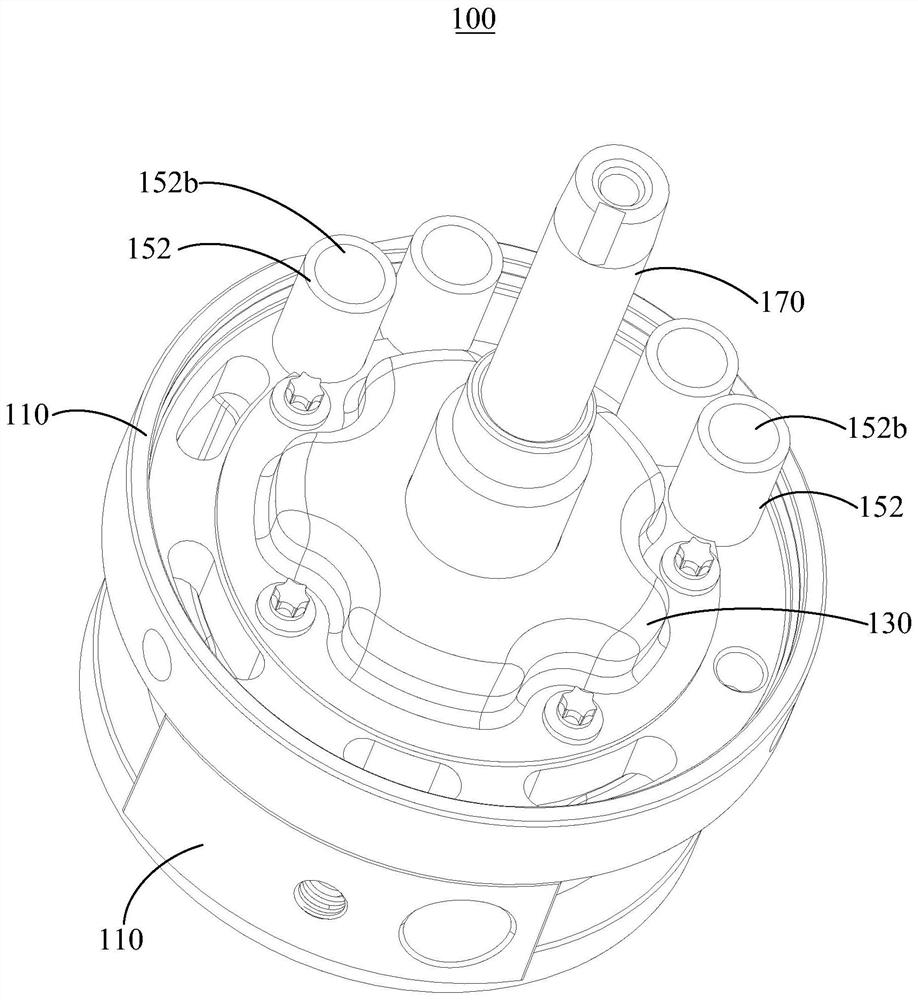

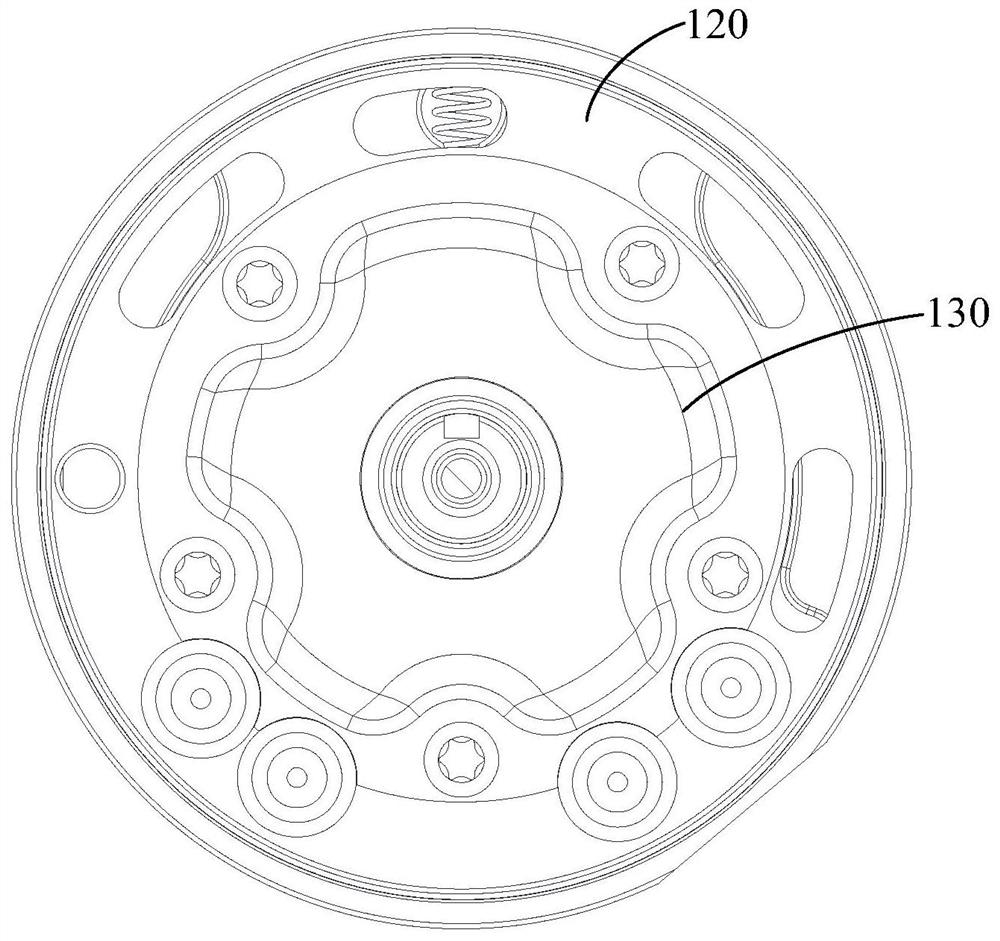

[0044]SeeFigure 1 to 9The present invention proposes a compressor 100 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com