Negative pressure balance draw shaft dust removal method

A chute and negative pressure technology, applied in the field of negative pressure balance chute dust removal, can solve the problems of uncontrollable humidification process, increasing fans, reducing dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

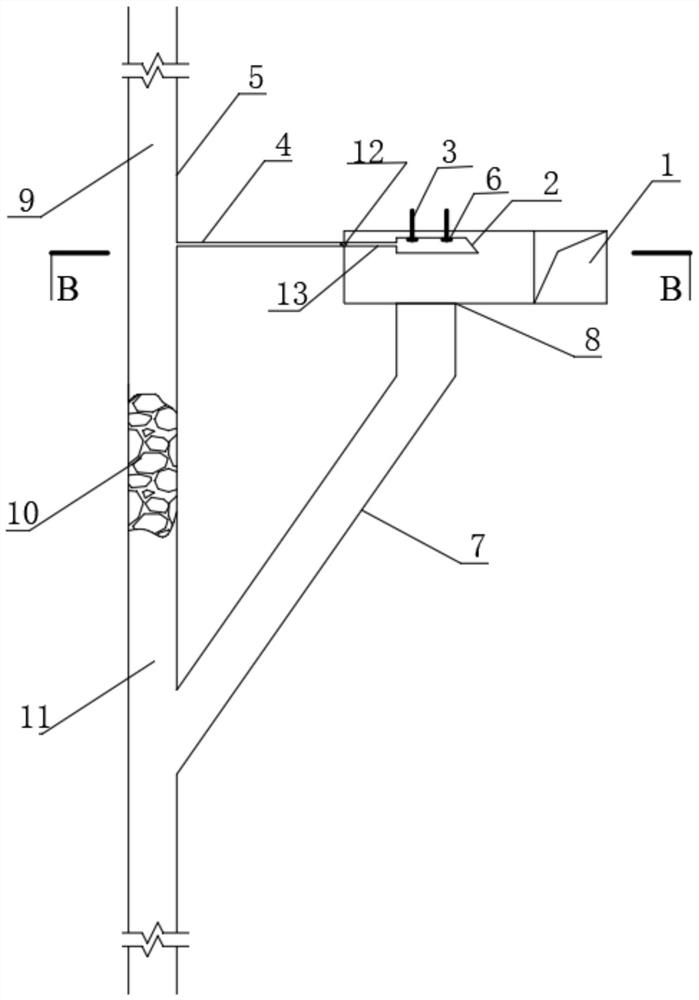

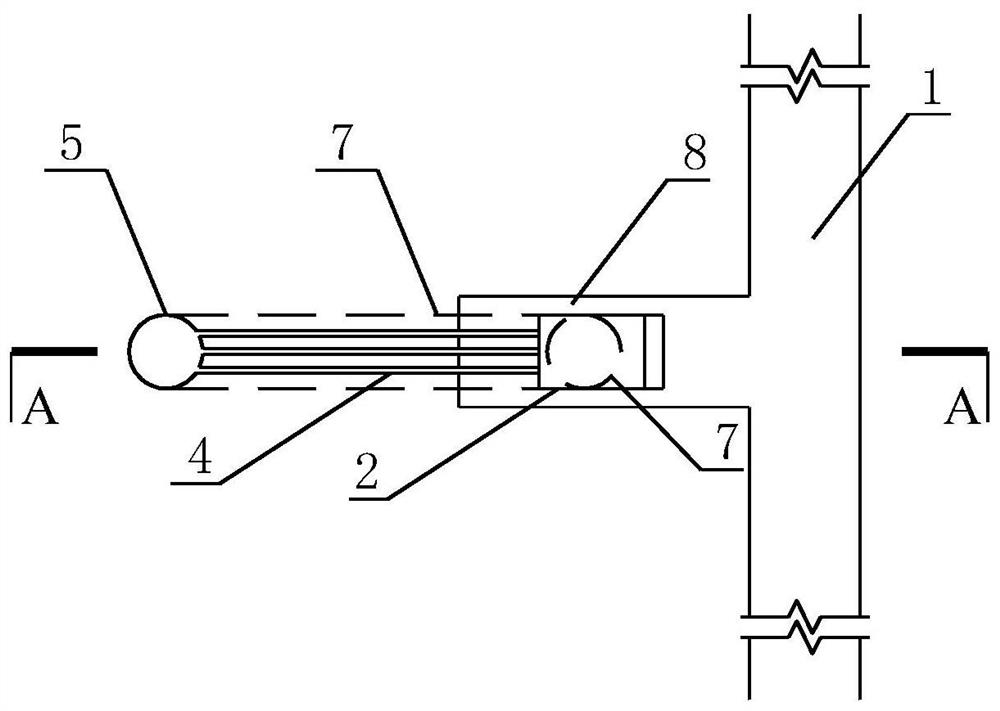

[0026] The technical solutions of the various embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them; based on the embodiments of the present invention, All other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0027] The main well of the ore body development system of a lead-zinc mine is a skip well, the wellhead elevation is 986m, the bottom elevation is 140m, the net diameter of the shaft is 4.2m, and it is supported by concrete. It adopts the lifting method of skip and counterweight, multi-rope floor-standing arrangement, and the shaft is equipped with 6.3m 3 One set of multi-rope bottom unloading skip, one set of 17.1t counterweight, steel wire rope tank road, undertake the task of lifting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Rod diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com