Automatic textile fabric cleaning equipment capable of preparing non-woven fabric cleaning liquid according to weight

A technology of automatic cleaning and cleaning liquid, which is applied in the direction of liquid/gas/steam fabric treatment, liquid/gas/steam treatment transmission, etc. It can solve the problems of poor cleaning effect, deformation of non-woven fabrics, inability to clean completely, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

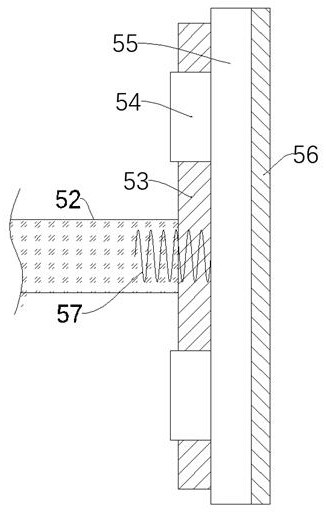

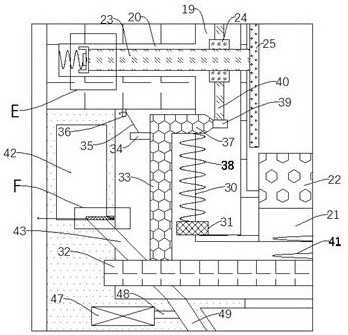

[0024] Combine below Figure 1-7 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0025] combined with Figure 1-7 The described automatic cleaning equipment for non-woven fabrics according to the weight of the non-woven fabric cleaning liquid, including the equipment assembly 10 and the work box 11 located in the equipment assembly 10, the work box 11 is fixed with a mechanism chamber 12 and a cleaning chamber 13 located on the lower side of the mechanism chamber 12, the mechanism chamber 12 is provided with a quantitative mechanism 14, and the quantitative mechanism 14 includes a mechanism trigger chamber 15 arranged on the top wall of the mechanism chamber 12 The left wall of the trigger chamber 15 of the mechanism is fixedly provided with a horizontal transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com