Hemp fabric and preparation method thereof

A technology of hemp and fabrics, applied in the direction of fabrics, textiles, plant fibers, etc., can solve the problems of not easy to shrink, not easy to wrinkle, etc., and achieve the effect of not easy to shrink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

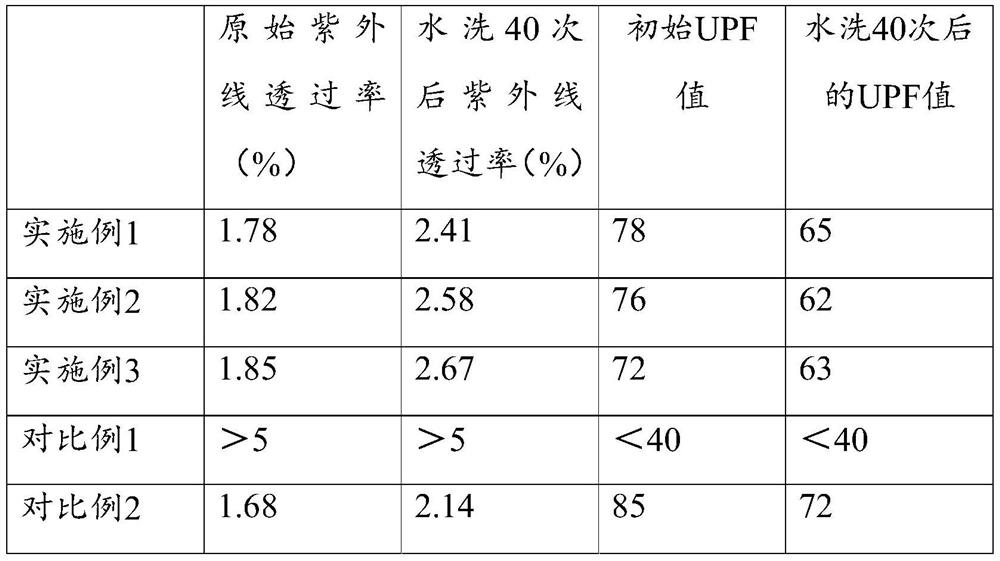

Examples

Embodiment 1

[0027] This embodiment proposes a hemp fabric, which is formed by blending cotton fibers as warp yarns and hemp cotton yarns as weft yarns; wherein, the weight ratio of the cotton fibers to the hemp cotton yarns is 56:44.

[0028] The preparation method of the hemp fabric of the present embodiment comprises the following steps:

[0029] 1) Warping process

[0030] The warp is warped, the warping speed is controlled at 400-420 m / min, the average weight of the tension disc is 3.3-3.5g, and the upper, middle and lower, front, middle and rear are used for arc-shaped segmentation;

[0031] 2) Sizing process

[0032] Sizing the warp yarn at a sizing speed of 60-65 m / min;

[0033] The slurry used includes the following raw materials in parts by weight: 8 parts of vegetable gum, 70 parts of rubber powder GR-796, 20.0 parts of complex starch TH-100, and the solid content of the slurry is 13.0%.

[0034] The present embodiment adopts single size groove sizing;

[0035] 3) Denting

...

Embodiment 2

[0040] This embodiment proposes a hemp fabric, which is formed by blending cotton fibers as warp yarns and hemp cotton yarns as weft yarns; wherein, the weight ratio of the cotton fibers to the hemp cotton yarns is 60:40.

[0041] 1) Warping process

[0042] For warping, the warping speed is controlled at 480-500 m / min, the average weight of the tension disc is 3.5-4.0g, and the upper, middle and lower, front, middle and rear are used for arc segmentation;

[0043] 2) Sizing process

[0044] Carry out sizing to warp yarn, sizing speed is 70-75 meter / min;

[0045] The slurry used includes the following raw materials in parts by weight: 5 parts of vegetable gum, 80 parts of rubber powder GR-796, 25 parts of complex starch TH-100, and the solid content of the slurry is 14.0%. Sizing with single size tank;

[0046] 3) Denting

[0047] Pass through the warp stopper, heddle and reed in sequence according to the design requirements of the upper machine diagram, and thread in stri...

Embodiment 3

[0052] This embodiment proposes a hemp fabric, which is formed by blending cotton fibers as warp yarns and hemp cotton yarns as weft yarns; wherein, the weight ratio of the cotton fibers to the hemp cotton yarns is 58:42.

[0053] 1) Warping process

[0054] For warping, the warping speed is controlled at 470-490 m / min, the average weight of the tension disc is 4.0-4.5g, and the upper, middle and lower, front, middle and rear are used for arc segmentation;

[0055] 2) Sizing process

[0056] Carry out sizing to warp yarn, sizing speed is 75-80 meter / min;

[0057] The used slurry includes the following raw materials in parts by weight: 10 parts of vegetable gum, 75 parts of rubber powder GR-796, 30 parts of complex starch TH-100, and the solid content of the slurry is 12.0%. Sizing with single size tank;

[0058] 3) Denting

[0059] Pass through the warp stopper, heddle and reed in sequence according to the design requirements of the upper machine diagram, and thread in str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com