Self-sealing magnetic oil absorption filter aluminum die-casting blank shell and machining process thereof

An oil filter and processing technology, which is applied to the aluminum die-casting blank shell of a self-sealing magnetic oil-absorbing filter and its processing technology, can solve the problems of poor wear resistance, wear, and shortening the service life of the aluminum casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

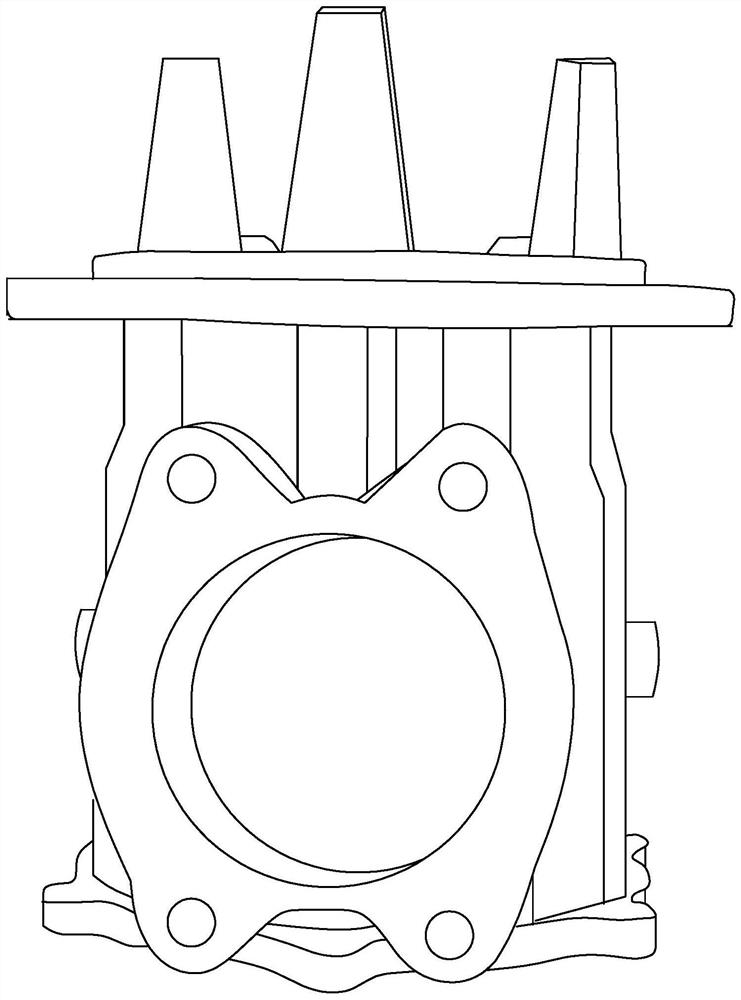

[0045] This application discloses a self-styled magnetic oil-absorbing filter aluminum die-cast blank shell and its processing technology. The aluminum die-cast blank shell of the self-styled magnetic oil-absorbing filter includes a shell body, and the shell body is as follows: figure 1 As shown; the shell body is processed by a surface treatment agent, and the raw materials of the surface treatment agent include polyamide resin; Propylene glycol fatty acid ester; Polytetrafluoroethylene; Polyacrylonitrile fiber; Ceramic micropowder, the processing technology includes the following steps:

[0046] S1. Grinding; grinding the shell body;

[0047] S2. Preparation of surface treatment agent; first mix polyamide resin and propylene glycol fatty acid ester, heat up to 50°C, and stir for 50 minutes; then add polytetrafluoroethylene, and continue stirring for 15 minutes; finally add polyacrylonitrile fiber and ceramic micropowder, Stir for 1 h, cool to room temperature to obtain a sur...

Embodiment 2

[0052] This application discloses a self-styled magnetic oil-absorbing filter aluminum die-cast blank shell and its processing technology. The aluminum die-cast blank shell of the self-styled magnetic oil-absorbing filter includes a shell body, and the shell body is as follows: figure 1 As shown; the shell body is processed by a surface treatment agent, and the raw materials of the surface treatment agent include polyamide resin; Propylene glycol fatty acid ester; Polytetrafluoroethylene; Polyacrylonitrile fiber; Ceramic micropowder, the processing technology includes the following steps:

[0053] S1. Grinding; grinding the shell body;

[0054] S2. Preparation of surface treatment agent; first mix polyamide resin and propylene glycol fatty acid ester, heat up to 60°C, and stir for 55 minutes; then add polytetrafluoroethylene, and continue stirring for 18 minutes; finally add polyacrylonitrile fiber and ceramic micropowder, Stir for 1.5h, and cool to room temperature to obtain ...

Embodiment 3

[0059] This application discloses a self-styled magnetic oil-absorbing filter aluminum die-cast blank shell and its processing technology. The aluminum die-cast blank shell of the self-styled magnetic oil-absorbing filter includes a shell body, and the shell body is as follows: figure 1 As shown; the shell body is processed by a surface treatment agent, and the raw materials of the surface treatment agent include polyamide resin; Propylene glycol fatty acid ester; Polytetrafluoroethylene; Polyacrylonitrile fiber; Ceramic micropowder, the processing technology includes the following steps:

[0060] S1. Grinding; grinding the shell body;

[0061] S2. Preparation of surface treatment agent; first mix polyamide resin and propylene glycol fatty acid ester, heat up to 55°C, and stir for 52 minutes; then add polytetrafluoroethylene, and continue stirring for 17 minutes; finally add polyacrylonitrile fiber and ceramic micropowder, Stir for 1.2h, cool to room temperature to obtain a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com