Epoxy composite propellant, preparation method and application thereof

A propellant, epoxy-based technology, applied in offensive equipment, ammonium perchlorate composition, non-explosive/non-thermal agent components, etc., can solve the problem of low fuel cost, easy deformation, and difficult to prepare and process double-base propellants And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned epoxy-based composite propellant comprises the following steps:

[0035] Step 1: Weigh and mix the liquid components, the liquid components include epoxy resin, 669 epoxy resin reactive diluent, mix evenly and wait for the bubbles to completely disappear before use;

[0036] Step 2: Weigh and mix the solid components, the solid components include ammonium perchlorate and lead oxide catalyst, mix well and set aside;

[0037] Step 3: Weigh the curing agent. The content of the curing agent is within the range of 3.3-4%. It is determined according to the actual curing demand. In the case of simple drug type and convenient filling, the content of the curing agent can be appropriately increased to speed up the curing speed, and vice versa reduce the content;

[0038] Step 4: Add the curing agent to the liquid component and mix quickly for 5-10 seconds, then add the solid component to the liquid component and stir evenly. The well-mix...

Embodiment 1

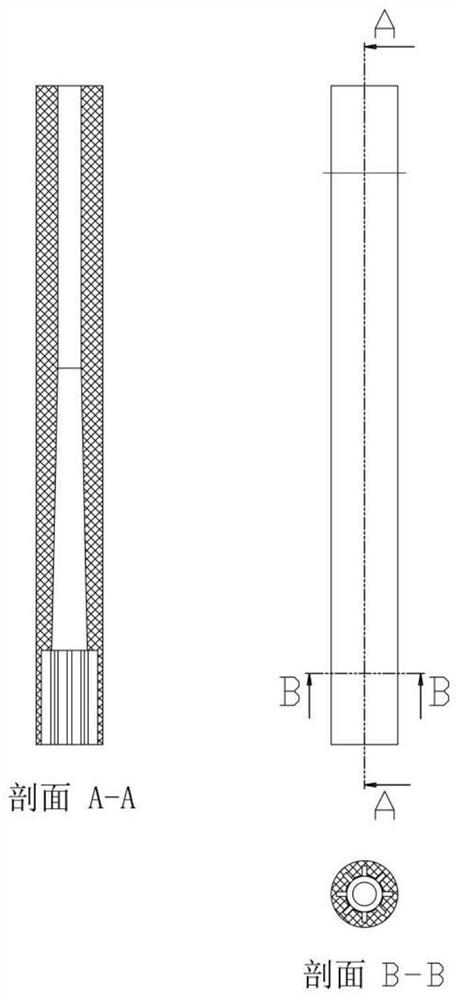

[0041] The above-mentioned propellant is processed and made into a solid rocket motor with a diameter of 82mm, and the actual test is carried out, such as figure 1 As shown in section A-A, the diameter of the grain column is 71mm, and it adopts a three-stage variable-section structure with a total length of 700mm. The upper end of the fuel is a circular hole, and the middle section is a circular hole variable-section expansion structure, as shown in figure 1 As shown in the section B-B, the lower end of the fuel is a star-shaped hole, and the epoxy resin mixed filler is used between the three sections of the grain for flame retardancy.

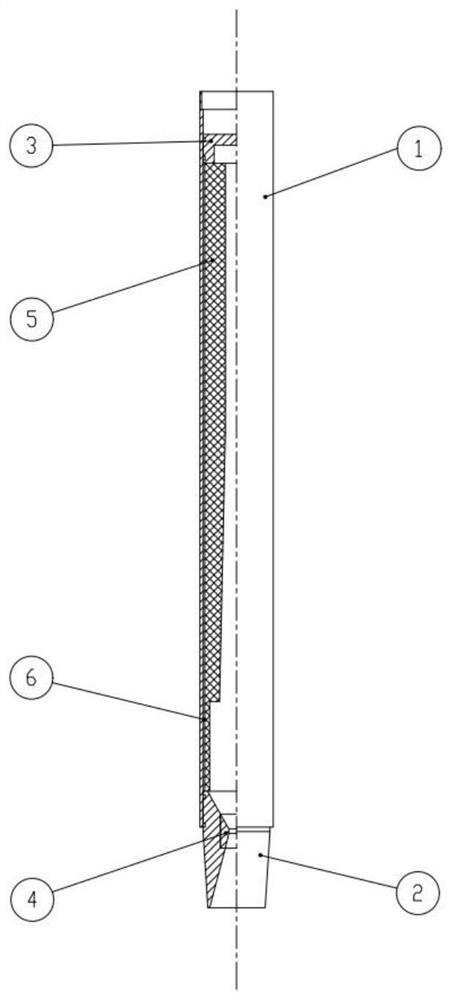

[0042] Such as figure 2 As shown, the engine is made of aluminum casing, the nozzle and plug are made of Bakelite, the throat lining is made of graphite, and there is a 2mm thick phenolic cloth pipe insulation layer outside the fuel powder column.

[0043] KNO is used in the test 3 , Mg, Al mixed ignition powder is ignited, the design ignit...

Embodiment 2

[0047] The above-mentioned propellant was processed to make a 55mm diameter solid rocket motor, and the actual test was carried out. Such as Figure 4 As shown in section A-A, the grain diameter is 46mm, adopts four-stage structure, and the total length is 440mm, such as Figure 4 As shown in section B-B, the upper end of the fuel is a circular hole with a flesh thickness of 14mm.

[0048] Such as Figure 5 As shown, the engine is made of aluminum casing, the nozzle and plug are made of Bakelite, the throat lining is made of graphite, and there is a 2mm thick phenolic cloth pipe insulation layer outside the fuel powder column.

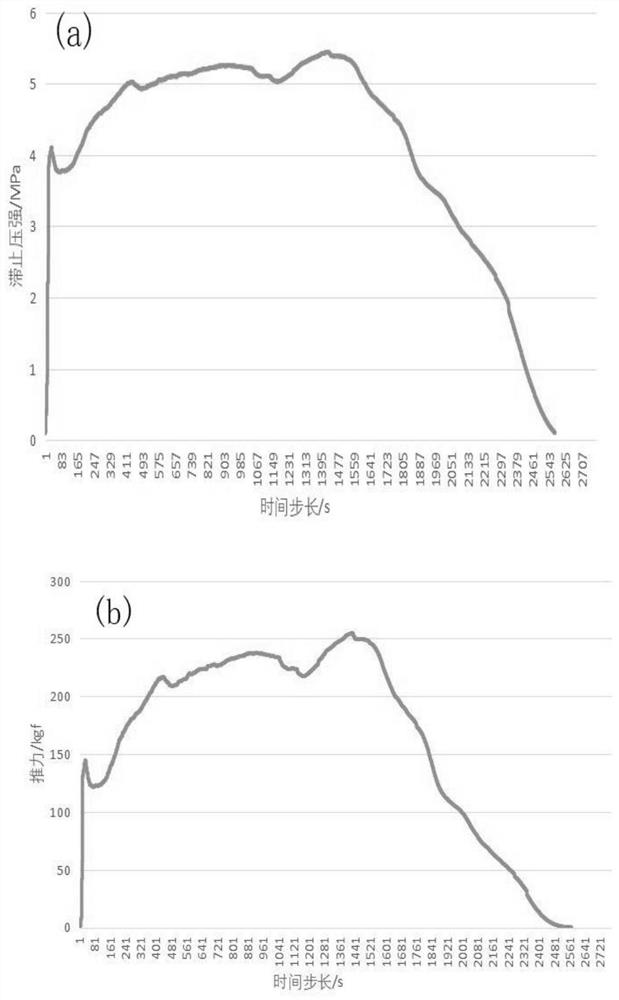

[0049] During the test, the ignition powder mixed with KNO3, Mg and Al was used for ignition, the design ignition pressure was 2MPa, and the pressure was measured at the plug (that is, the upper end of the fuel), and the following results were obtained: Image 6 In the stagnation pressure and thrust curve shown in the figure, a buffer tube and a press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com