Multifunctional ultrathin surface layer material for roads and application thereof

A multi-functional, surface layer technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of difficult control of the production process, single improvement of the asphalt surface layer, and high construction costs, and achieves the benefits of road drainage and improved oil pollution resistance. , Outstanding flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention is further explained below in connection with the specific embodiments, but is not limited to the present invention.

[0040][Example]

[0041]Multifunctional composite filler preparation

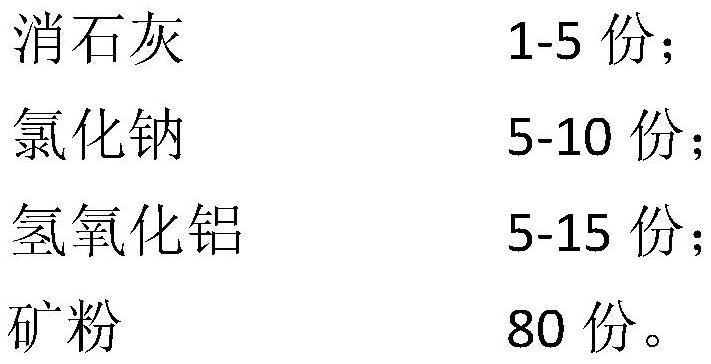

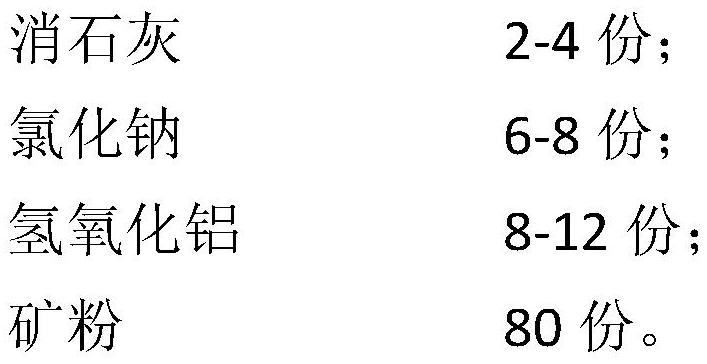

[0042]Table 1: Multi-function composite filler raw materials

[0043] Filler 1 Filler 2 Filler 3 Filler 4 Filler 5 Caviminate, kg 23433 Sodium chloride, kg 67807 Aluminum hydroxide, kg 81012100 Mine powder, kg 8080808790

[0044]After the amount of lime, sodium chloride, aluminum hydroxide, and ore powder is mixed, and the multi-function composite filler is ground, and the multi-function composite filler is ground.

[0045]2. Modified anti-oily asphalt preparation

[0046]Table 2: Modified anti-oily asphalt raw materials

[0047] Asphalt 1 Asphalt 2 Asphalt 3 Asphalt 4 Asphalt 5 Asphalt 6 Long chain alkyl silicone oil, kg 2341000 Glycerin, kg 8760100 SBS modified asphalt, kg9090909090100

[0048]The recipe amounts of long chain alkyl silicone oil, glycerol and SBS modified asphalt were m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com