Comfortable high-breathability composite material and preparation method thereof

A composite material and high-breathability technology, applied in chemical instruments and methods, other household appliances, synthetic resin layered products, etc., can solve problems such as easy to feel stuffy, calcium carbonate powder precipitation, foreign matter pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

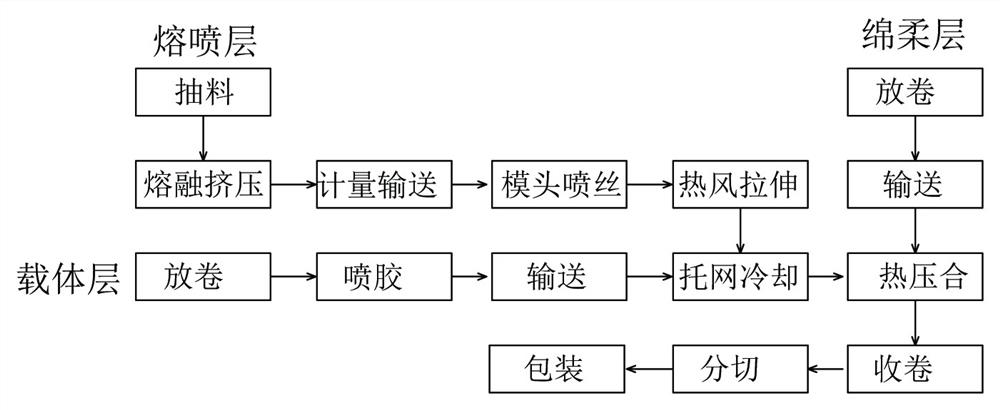

Method used

Image

Examples

Embodiment 1

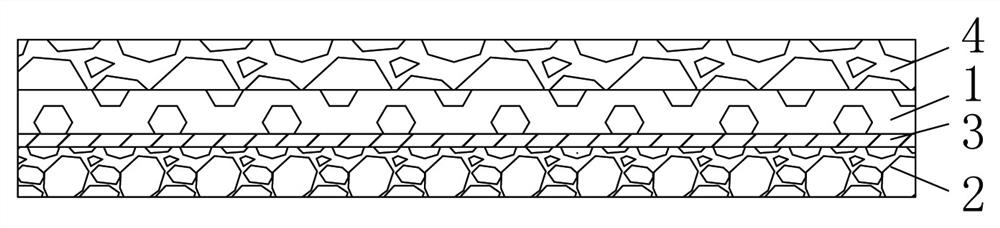

[0057] refer to figure 1 , a comfortable and highly breathable composite material, which is sequentially formed by heat-compression bonding of a soft layer 4, a melt-blown layer 1 and a carrier layer 2, the melt-blown layer 1 is composed of polypropylene masterbatch melt-blown, and the carrier layer 2 It is composed of spunbond nonwoven fabric or hot air nonwoven fabric, and the soft layer 4 is made of hot air nonwoven fabric, supersoft spunbond nonwoven fabric or pure cotton nonwoven fabric, which is formed by compounding online melt blown and nonwoven fabric The moisture permeability of the composite material can be above 4000g / m2 / 24hr, and the water pressure resistance can reach above 30mbar; the soft layer 4 can improve the soft comfort and application performance of the composite material, so that both sides of the meltblown layer have a protective layer , to protect the melt-blown layer that is prone to embrittlement and rupture, and to avoid direct contact of the melt-b...

Embodiment 2

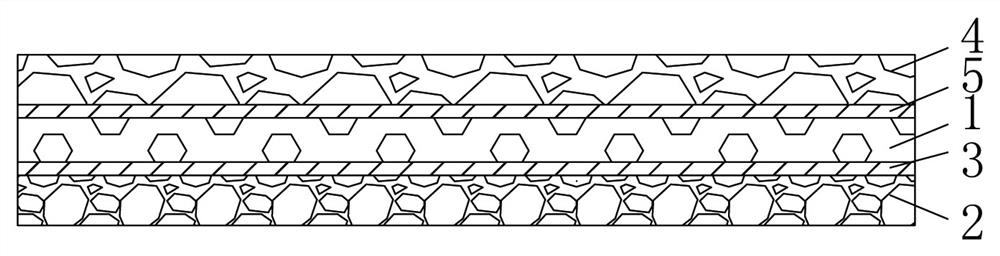

[0075] refer to image 3 , a comfortable and highly breathable composite material, which is sequentially formed by heat-compression bonding of a soft layer 4, a melt-blown layer 1 and a carrier layer 2, the melt-blown layer 1 is composed of polypropylene masterbatch melt-blown, and the carrier layer 2 It is composed of spunbond nonwoven fabric or hot air nonwoven fabric, and the soft layer 4 is made of hot air nonwoven fabric, supersoft spunbond nonwoven fabric or pure cotton nonwoven fabric, which is formed by compounding online melt blown and nonwoven fabric The moisture permeability of the composite material can be above 4000g / m2 / 24hr, and the water pressure resistance can reach above 30mbar; the soft layer 4 can improve the soft comfort and application performance of the composite material, so that both sides of the meltblown layer have a protective layer , to protect the melt-blown layer that is prone to embrittlement and rupture, and to avoid direct contact of the melt-b...

Embodiment 3

[0096] refer to Figure 5 , a comfortable and highly breathable composite material, which is sequentially formed by heat-compression bonding of a soft layer 4, a melt-blown layer 1 and a carrier layer 2, the melt-blown layer 1 is composed of polypropylene masterbatch melt-blown, and the carrier layer 2 It is composed of spunbond nonwoven fabric or hot air nonwoven fabric, and the soft layer 4 is made of hot air nonwoven fabric, supersoft spunbond nonwoven fabric or pure cotton nonwoven fabric, which is formed by compounding online melt blown and nonwoven fabric The moisture permeability of the composite material can be above 4000g / m2 / 24hr, and the water pressure resistance can reach above 30mbar; the soft layer 4 can improve the soft comfort and application performance of the composite material, so that both sides of the meltblown layer have a protective layer , to protect the melt-blown layer that is prone to embrittlement and rupture, and to avoid direct contact of the melt-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com