Six-linkage polishing equipment and rear device and method thereof

A technology of six linkages and equipment, applied in the direction of grinding/polishing equipment, grinding drive device, grinding automatic control device, etc., can solve the problems of limited precision, limited processing, difficult polishing process, etc., and achieve high precision , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

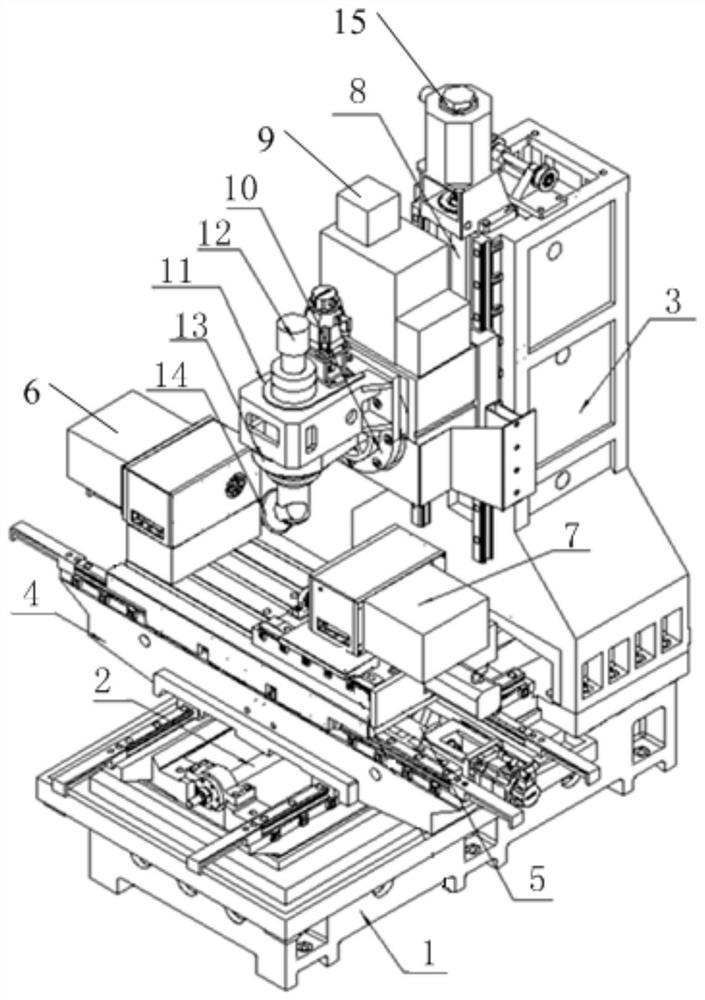

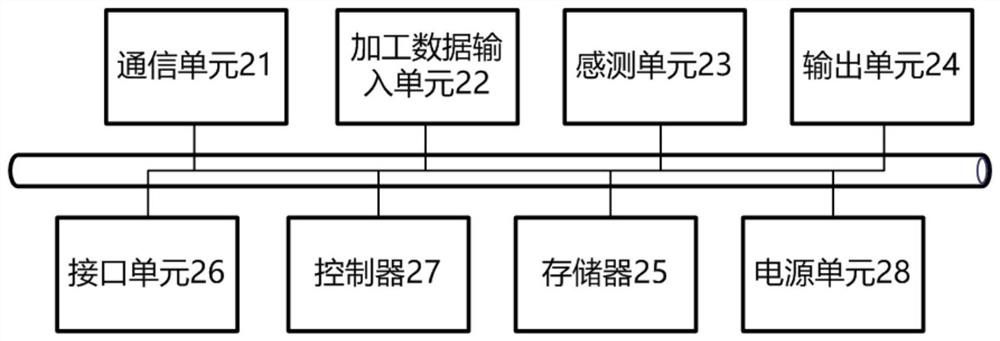

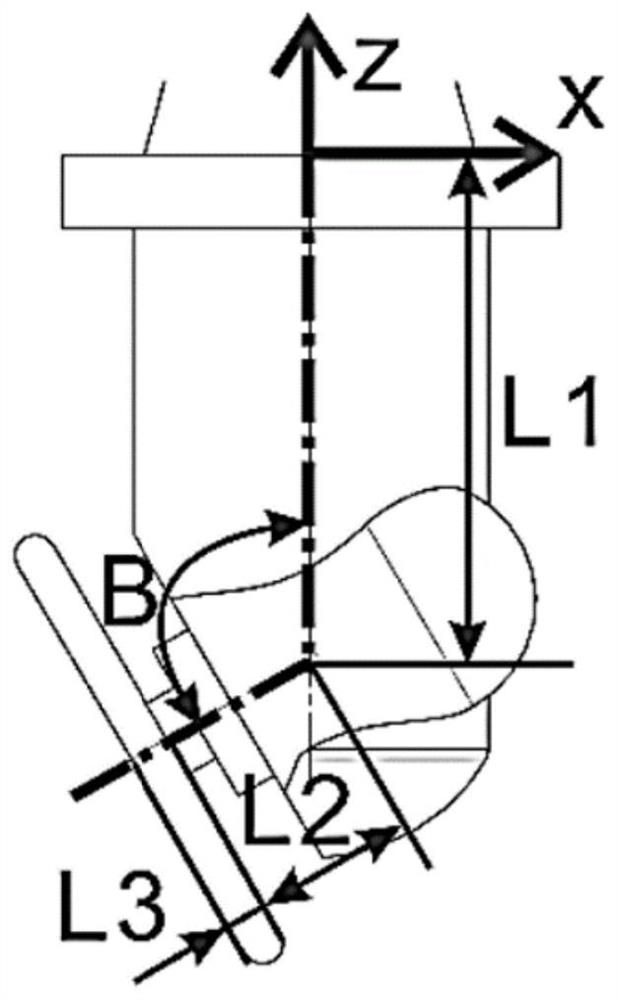

[0065]The present invention provides a six-link polishing apparatus and its post devices, such asfigure 1 withfigure 2 As shown, the base 1; the base 1 is mounted on the base 1, and the X-direction rail 2 is slidably connected to the slide rail 2; the longitudinal table 4 is provided with X-direction rail 2 The Y-to-rail 5 of the vertically disposed is fixed to one end of the slide rail 5, and the Y is slid to the slide rail 5 and there is a lateral table 7;

[0066]The fixed processing seat 6 is provided with a first clamping mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com