A kind of aluminum bar isometric cutting equipment

A technology of equidistant cutting and aluminum rods, applied in the direction of metal sawing equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of preventing self-moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

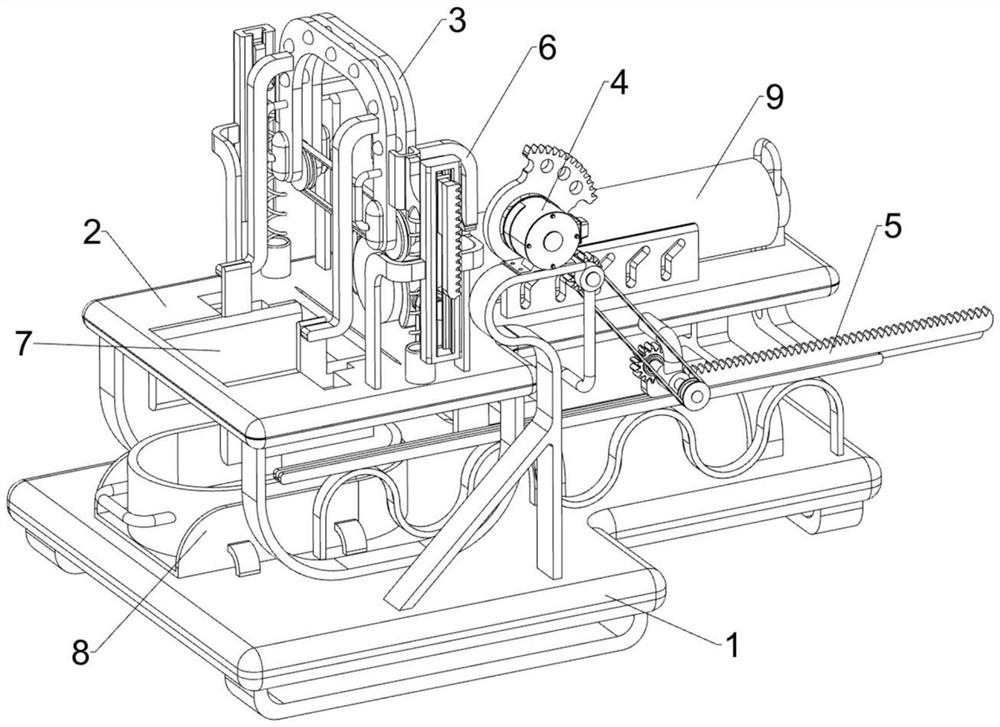

[0030] An aluminum bar isometric cutting equipment, such as Figure 1 to Figure 3 As shown, it includes a base 1, a worktable 2, a cutting mechanism 3 and a driving mechanism 4. The top of the base 1 is connected with a worktable 2, an opening is opened on the left side of the top of the worktable 2, a cutting mechanism 3 is installed on the top of the worktable 2, and the base 1. A driving mechanism 4 is installed on the top, and the driving mechanism 4 is connected with the cutting mechanism 3 in a driving manner.

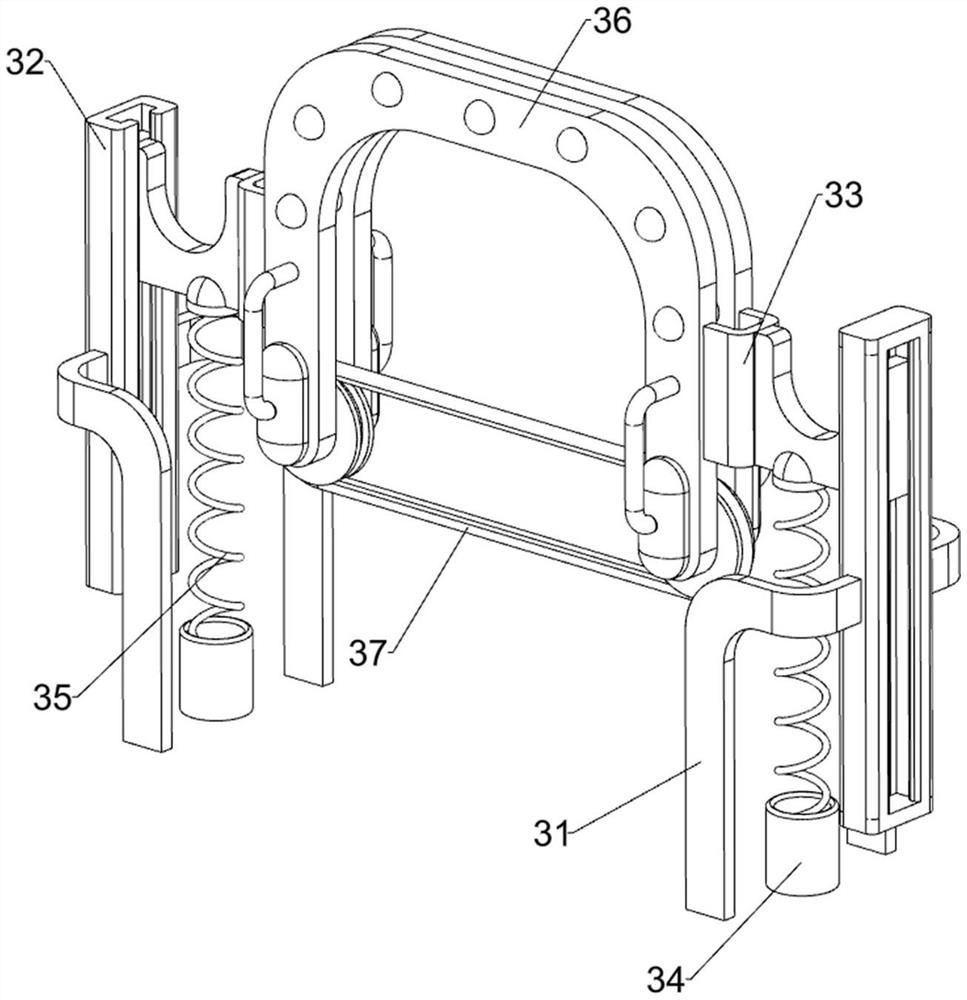

[0031] The cutting mechanism 3 includes a first fixing frame 31, a first guide rail frame 32, a connecting frame 33, a sleeve seat 34, a support spring 35, a mounting frame 36 and an electric cutting belt 37. Two first fixing frames 31 are connected symmetrically on the left and right sides, a first guide rail frame 32 is connected between the two first fixing frames 31 on the left and right sides, and a connecting frame 33 is slidably connected between the first...

Embodiment 2

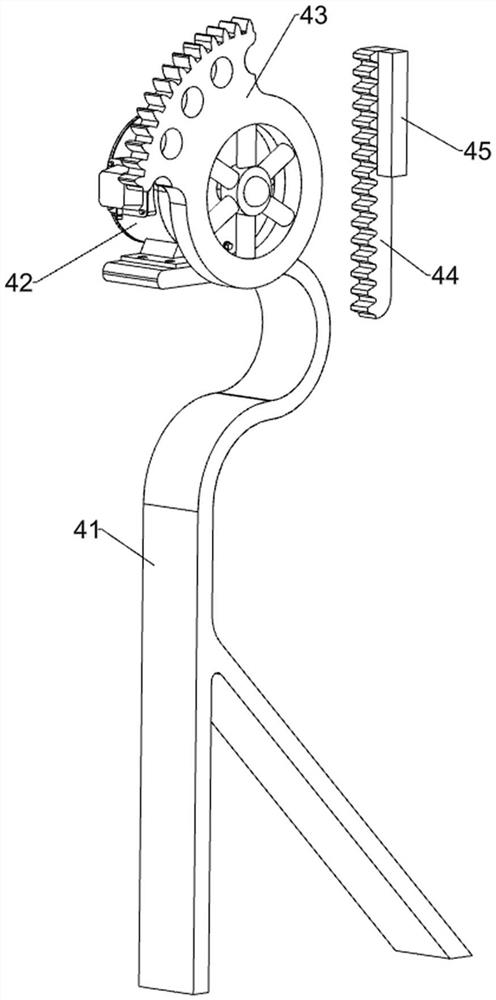

[0035] On the basis of Example 1, as figure 1 and Figure 4As shown, a push mechanism 5 is also included, and the push mechanism 5 includes a first positioning frame 51, a first gear 52, a transmission belt set 53, a second positioning frame 54, a one-way clutch 55, a second gear 56, a second tooth The bar frame 57 , the second guide rail frame 58 , the push block 59 and the handle 510 , a first positioning frame 51 is connected to the front side of the worktable 2 , and a first gear 52 is rotatably connected to the first positioning frame 51 . The sector gear 43 is matched, the front side of the worktable 2 is connected with a second positioning frame 54, the second positioning frame 54 is located on the right side of the first positioning frame 51, and a rotating rod is rotatably connected in the second positioning frame 54, and the rotating rod is connected with the first positioning frame 54. A transmission belt set 53 is connected between the transmission shaft of a gear...

Embodiment 3

[0038] On the basis of Example 2, as figure 1 and Figure 5 As shown, a clamping mechanism 6 is also included. The clamping mechanism 6 includes a mounting seat 61, a directional clamping plate frame 62, a return spring 63, a wedge-shaped block rod 64, a wedge-shaped block frame 65 and a limit side plate 66. The top of the workbench 2 There are two mounting seats 61 symmetrically connected in front and rear on the left side. The mounting seat 61 is located on the inner side of the first fixing frame 31 . The mounting seat 61 is slidably connected with a directional splint frame 62 . The return spring 63, the right side of the directional splint frame 62 is connected with a wedge-shaped block rod 64, the right side of the mounting frame 36 is connected with two wedge-shaped block frames 65 symmetrically in front and back, and the wedge-shaped block frame 65 cooperates with the wedge-shaped block rod 64, the workbench 2 Two limit side plates 66 are connected to the top symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com