Cylinder component hot-extrusion die and forming method

A hot extrusion die, hot extrusion technology, applied in the direction of metal extrusion die, metal extrusion, metal extrusion control equipment, etc., can solve problems such as difficulty in demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

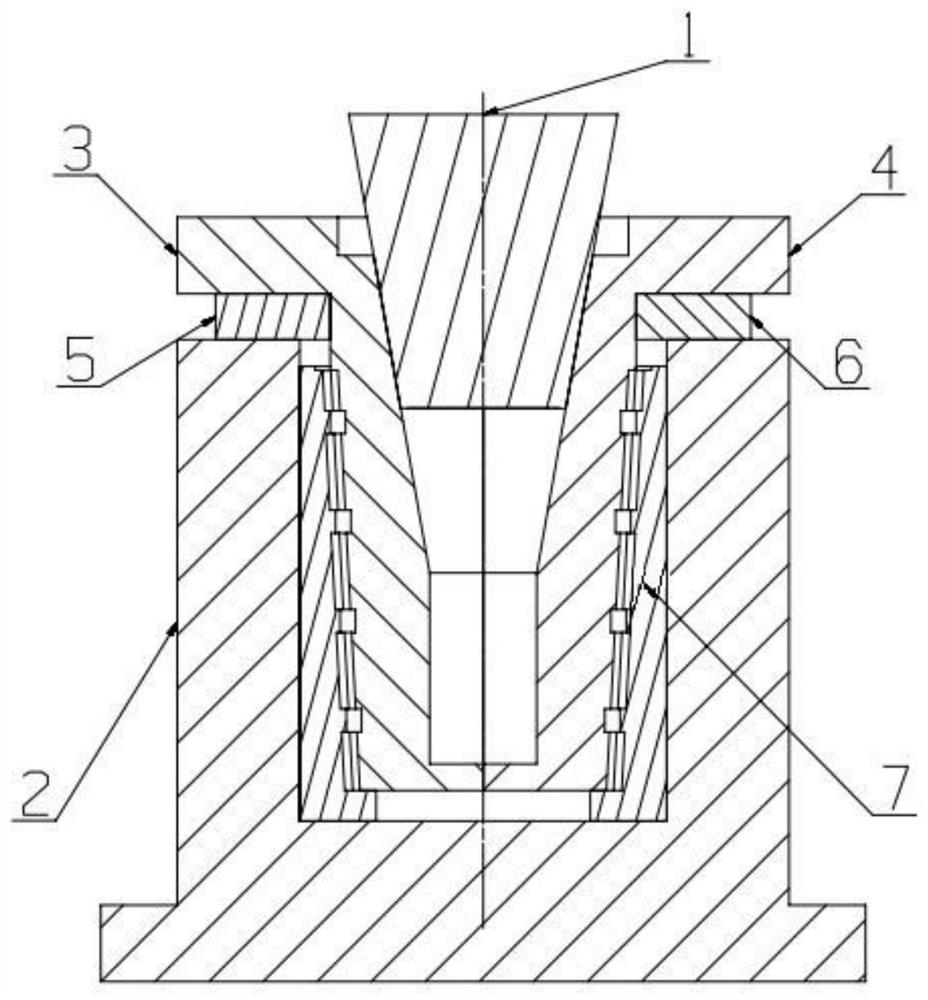

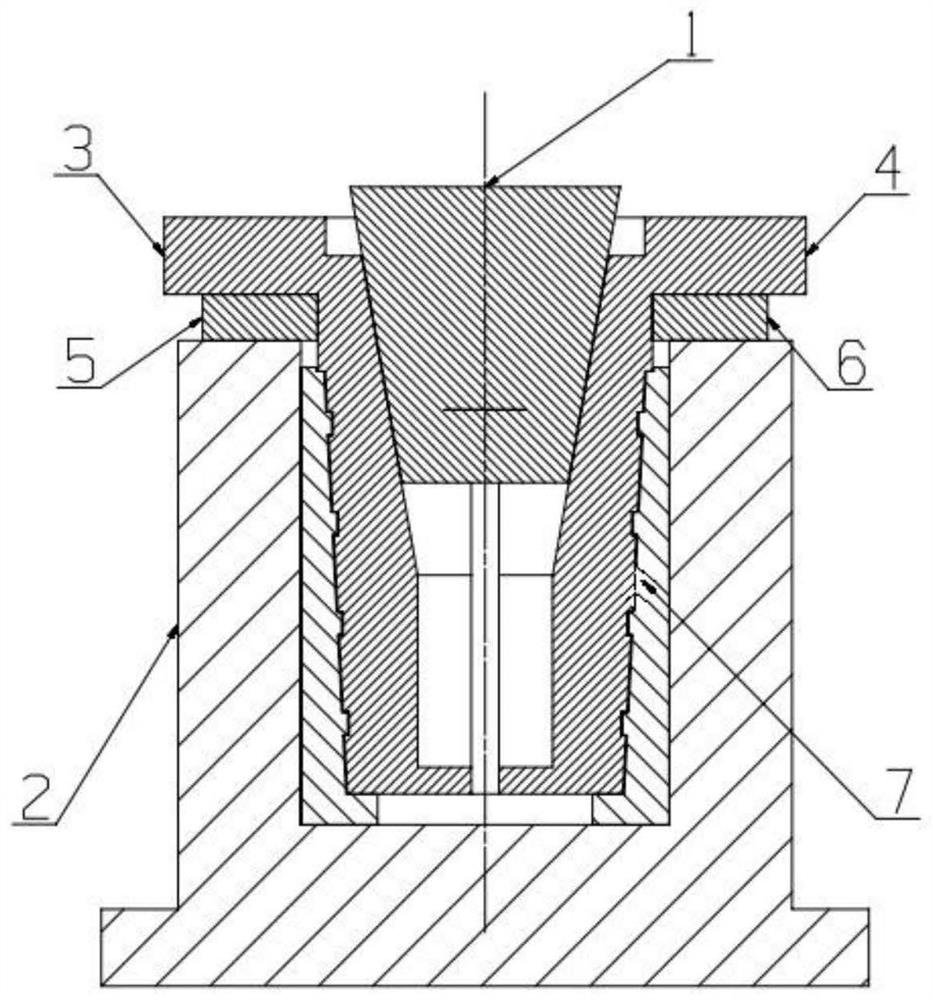

[0046] A specific embodiment of the present invention, combined with Figure 1-7 To illustrate, a hot extrusion die for a cylindrical member is disclosed, including: an upper die core 1 , a punch, a stop ring and a lower die 2 .

[0047] Furthermore, the outer surface of the upper mold core 1 is conical, the taper of the inclined surface is 1°-10°, and the height of the conical surface is 300mm-1000mm. The upper mold core 1 and the hydraulic cylinder equipped on the hydraulic press platform pass through the flange It is integrated with the bolt fastening, and the maximum movement stroke of the upper mold core 1 is 50mm-300mm.

[0048] Further, the punch includes a left punch 3 and a right punch 4, the left punch 3 and the right punch 4 are symmetrically arranged, installed on the upper mold platform of the hot extrusion equipment, the left punch 3 and the right punch 4 The surface of the inner cavity and the outer surface of the upper mold core 1 are in a wedge-shaped fit rel...

Embodiment 2

[0066] This embodiment provides a method for forming a hot extrusion die for a cylindrical member, mainly using the hot extrusion die for a cylindrical member provided in Example 1 to carry out composite hot extrusion forming on the extrusion blank of the cylindrical body, combined with the attached Figure 1-4 Instructions, including:

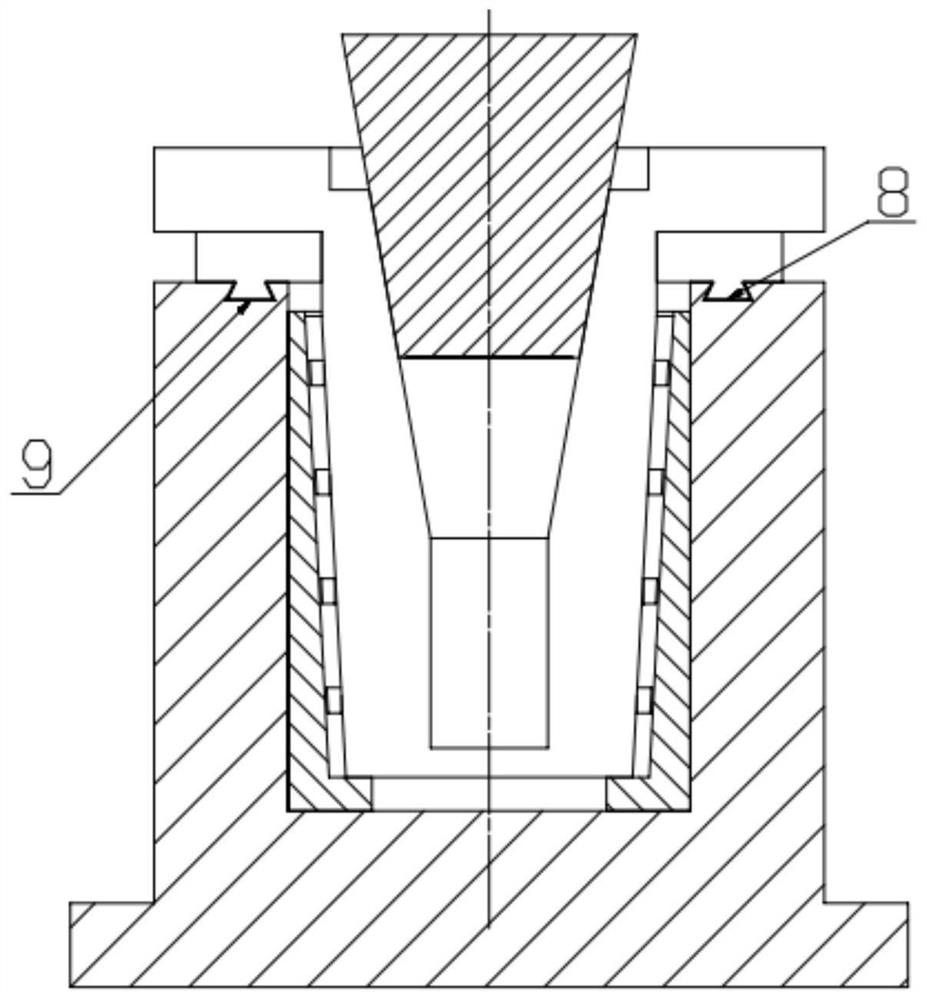

[0067] Step 1: Mold making. Manufacture and process hot extrusion dies based on the three-dimensional model of the cylindrical member that needs to be formed. The hot extrusion die includes: an upper die core 1, a punch, a limit ring, and a lower die 2, the punch includes a left punch 3 and a right punch 4, and the limit ring includes a left limit ring 5 symmetrically installed And right limit ring 6. The bottom end faces of the left limit ring 5 and the right limit ring 6 are provided with a slide rail 8 , and the upper end face of the lower mold 2 is provided with a slide groove 9 . According to the shape of the cylindrical member to be p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Draft angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com