Air curtain and cloth bag combined dust removal device suitable for transfer system

A technology of a dust removal device and a dry dust collector, which is applied to cleaning devices, smoke removal, transportation and packaging, etc., can solve the problems of personnel health and equipment safety production, insignificant and excessive dust reduction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

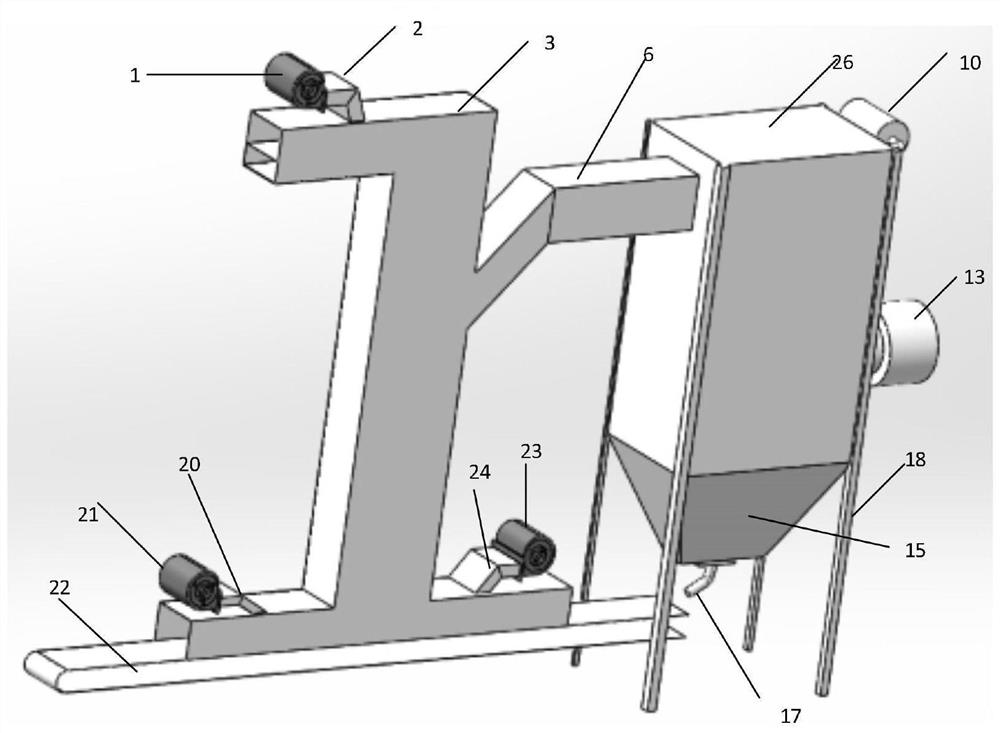

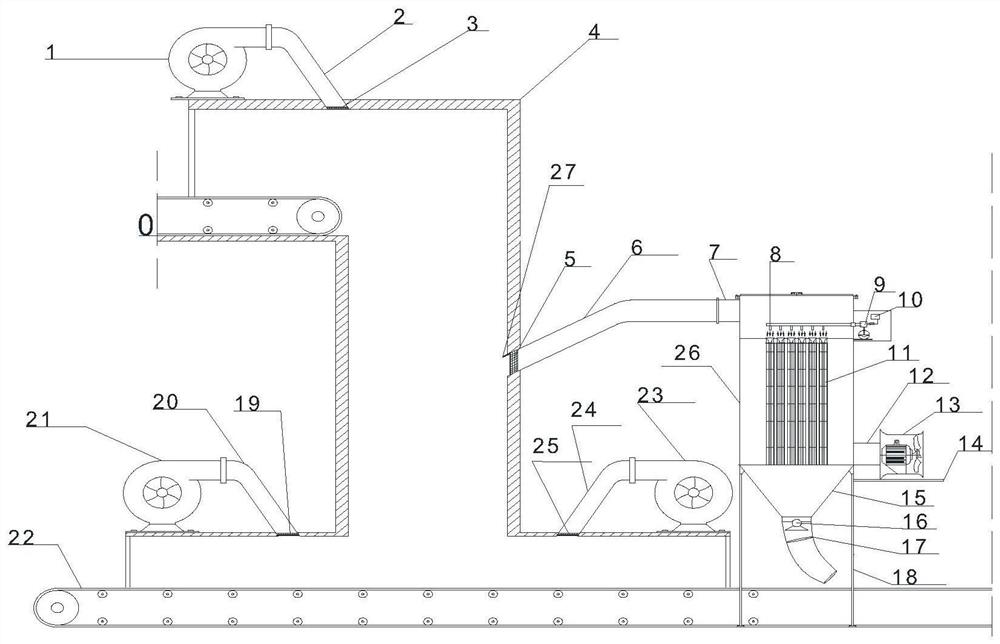

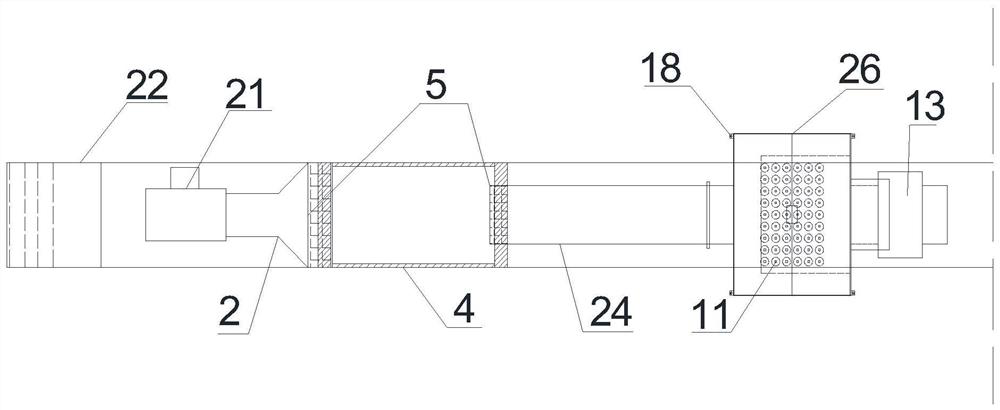

[0019] Such as Figure 1~3 Shown is a combined air curtain and bag dust removal device suitable for reprinting systems, including a first fan 1, a second fan 21, a third fan 23, a first air duct 2, a second air duct 20, and a third air duct 24 , the fourth air duct 12, the dry dust collector 26; the first air duct 2 is arranged on the pipe wall side of the feed inlet of the transfer system 4, and the second air duct 20 is arranged at the first outlet of the transfer system 4 guide groove On the side of the upper pipe wall, the third air pipe 24 is arranged on the upper pipe wall side of the second outlet of the transfer system 4 guide groove, and the second air pipe 20 and the third air pipe 24 are in a symmetrical relationship; the fourth air pipe 12 It is arranged on the right side of the pipe wall of the discharge pipe and forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com