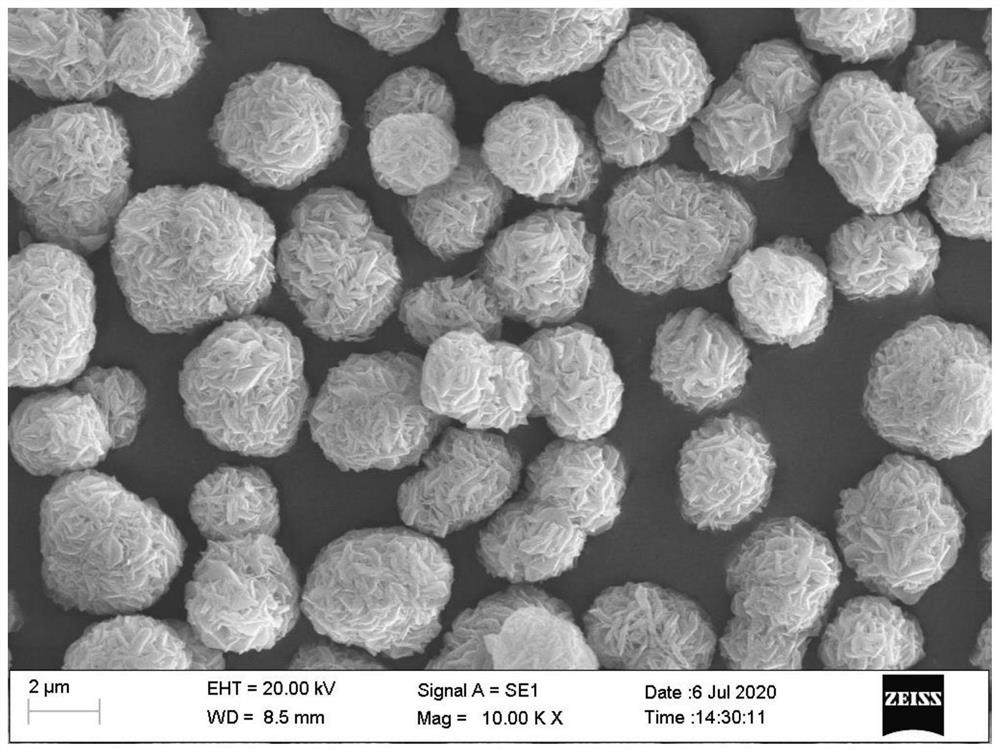

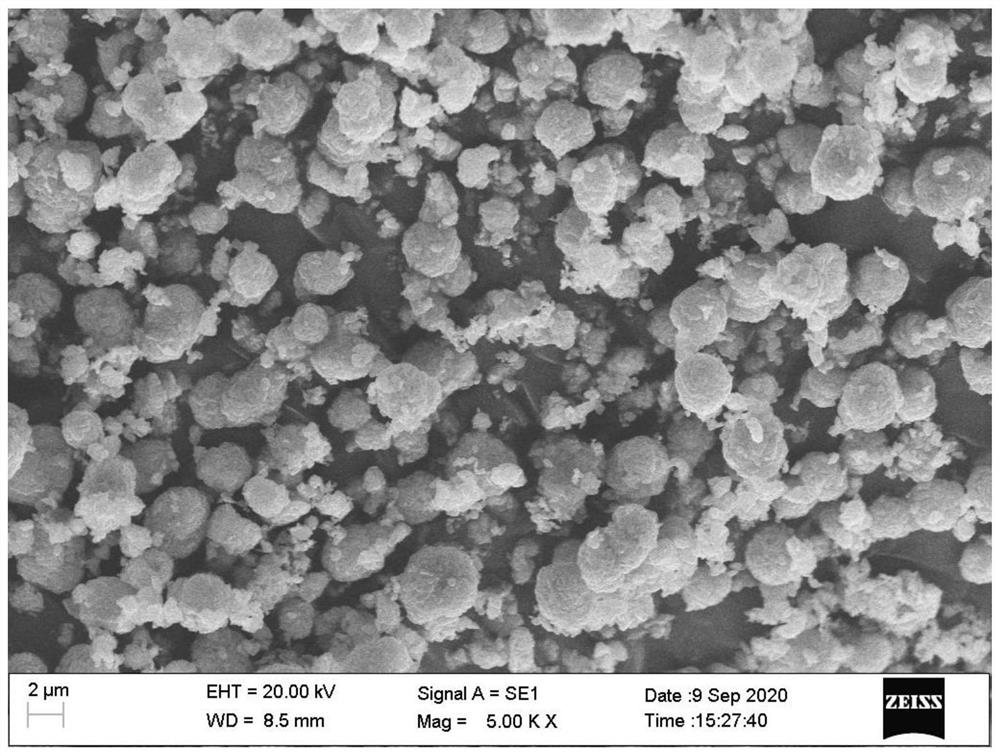

High-nickel ternary positive electrode material and preparation method thereof

A positive electrode material and high-nickel technology, applied in the field of materials, can solve the problems of poor material uniformity, uneven lithium mixing, cycle performance, rate performance, storage performance and high temperature performance, and achieve splash prevention, excellent uniformity and crystallinity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment discloses a high-nickel ternary positive electrode material and a preparation method thereof, comprising the following steps:

[0038] Step 1. Take a certain amount of NCM622 precursor in the roasting furnace with stirring function, set the stirring speed to 120 rpm, and the heating program is: increase from room temperature to 280 °C at a heating rate of 3 °C / min, and keep the temperature at this temperature. 3h, after the program is finished, cool down to room temperature with the furnace;

[0039] Step 2, according to the molar ratio n (Li) / n (Ni+Co+Mn) =1.10 Weigh the lithium source and NCM622 oxide respectively, and place them in a roasting furnace with stirring function after premixing;

[0040] Step 3. Set the stirring speed to 300 rpm, and the heating program is: the first stage: raise the temperature from room temperature to 500 °C at a heating rate of 4 °C / min, keep at this temperature for 5 hours, and the second stage: increase the temperat...

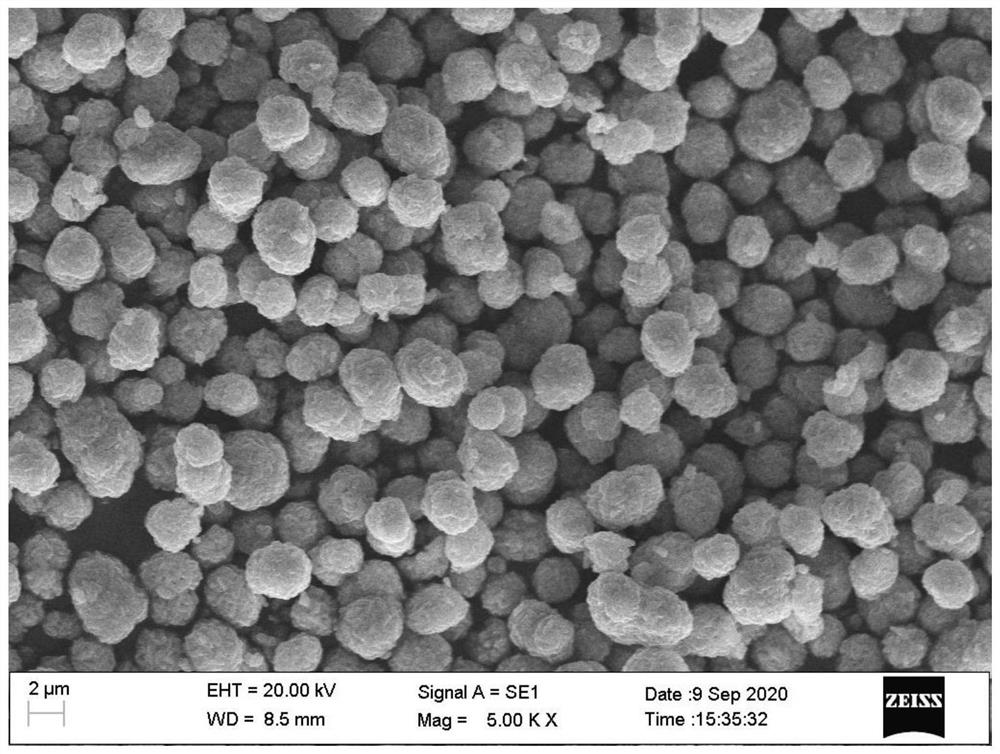

Embodiment 2

[0043] This embodiment discloses a high-nickel ternary positive electrode material and a preparation method thereof, comprising the following steps:

[0044] Step 1. Take a certain amount of NCM622 precursor in a roasting furnace with stirring function, set the stirring speed to 150rpm, and the heating program is: increase the temperature from room temperature to 300°C at a heating rate of 3°C / min, and keep warm at this temperature 3h, after the end of the program, cool down to room temperature with the furnace;

[0045] Step 2, according to the molar ratio n (Li) / n (Ni+Co+Mn) =1.20 Take by weighing lithium source and NCM622 oxide respectively, place in the calciner with stirring function after premixing;

[0046] Step 3. Set the stirring speed to 250rpm, and the heating program is as follows: the first section: raise the temperature from room temperature to 500°C at a heating rate of 4°C / min, and keep at this temperature for 5 hours; Min heating rate, raised to 800 ° C, k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com