Micro-perforated corrugated-honeycomb metamaterial plate structure capable of improving sound insulation and absorption performance

A technology of metamaterials and plate structures, applied in the direction of sound-generating devices, instruments, layered products, etc., can solve the problems of limited mechanical and acoustic properties, poor sound insulation and sound absorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

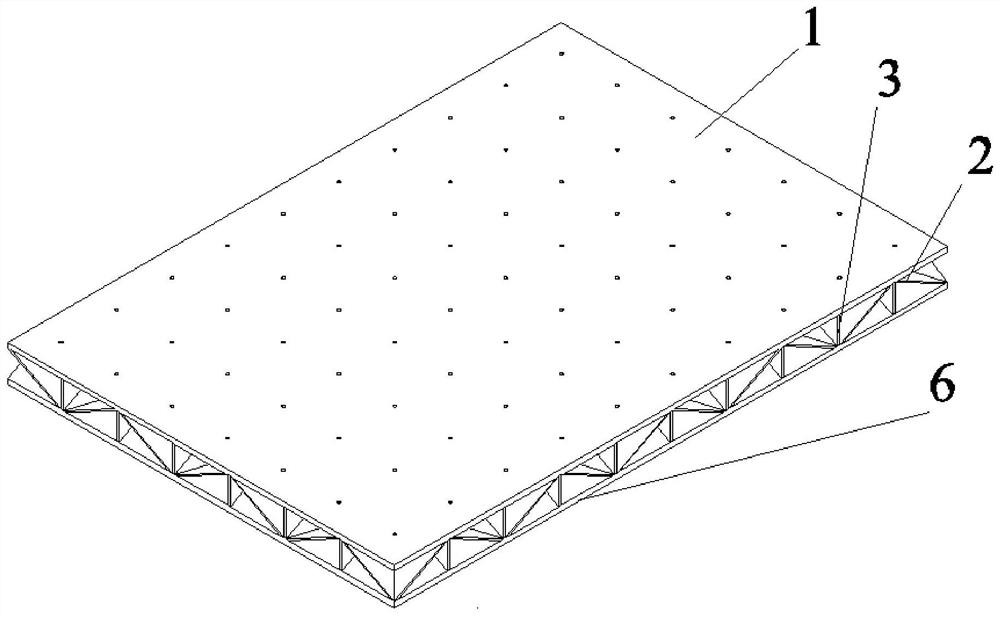

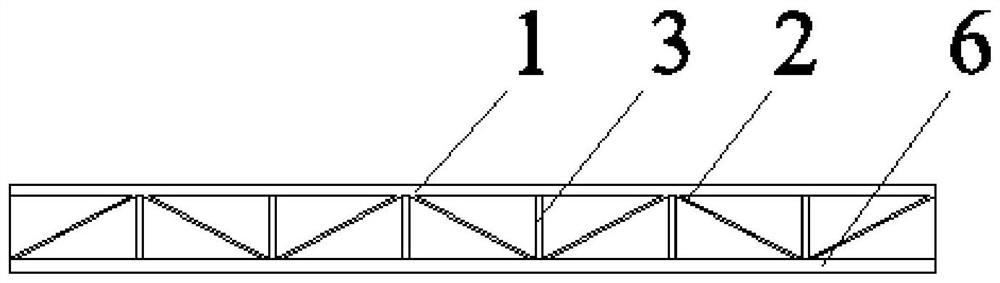

[0025] Specific implementation mode one: refer to Figure 1 to Figure 8 This embodiment is described. This embodiment provides a micro-perforated corrugated-honeycomb metamaterial plate structure that improves sound insulation and absorption performance. The metamaterial plate structure includes a corrugated-honeycomb metamaterial sandwich plate and 4N local resonance mechanisms. N is a positive integer;

[0026] The corrugated-honeycomb metamaterial sandwich panel includes a top plate 1, N corrugated-honeycomb sandwich units and a bottom plate 6, and N corrugated-honeycomb sandwich units are periodically arranged between the top plate 1 and the bottom plate 6, and two adjacent The two corrugated-honeycomb sandwich units are separated by a partition, the top of each corrugated-honeycomb sandwich unit is fixedly connected with the lower surface of the top plate 1, and the bottom of each corrugated-honeycomb sandwich unit is connected with the upper surface of the bottom plate 6...

specific Embodiment approach 2

[0028] Specific implementation mode two: refer to Figure 1 to Figure 8 Describe this embodiment, this embodiment is to further limit the corrugated-honeycomb sandwich unit described in the first specific embodiment, in this embodiment, the corrugated-honeycomb sandwich unit includes corrugated sandwich 2 and honeycomb sandwich 3 ;

[0029] The honeycomb sandwich core 3 is a cross plate structure, and the corrugated sandwich core 2 includes four sets of right-angled triangular plates, each set of right-angled triangular plates is arranged in a quadrant in the honeycomb sandwich core 3, and two sets of right-angled triangular plates in each set of right-angled triangular plates The triangular plates are arranged symmetrically along the diagonals of the quadrants, and one side of each right-angled triangular plate in each group of right-angled triangular plates is fixedly connected with the top of the corresponding cross plate in the quadrant. The opposite apex connected to the...

specific Embodiment approach 3

[0031] Specific implementation mode three: refer to Figure 1 to Figure 8 Describe this embodiment. This embodiment is to further limit the local resonance mechanism described in the second specific embodiment. In this embodiment, each local resonance mechanism includes a mass block 4 and a rubber spring 5. The rubber spring 5 is arranged on the bottom plate 6 along the vertical direction, and one end of the rubber spring 5 is fixedly connected to the top surface of the bottom plate 6 , the mass block 4 is arranged on the rubber spring 5 , and the mass block 4 is fixedly connected to the other end of the rubber spring 5 . Other compositions and connection methods are the same as those in the second embodiment.

[0032] In this embodiment, the local resonance mechanism is attached to the bottom plate by applying the mass block 4 and the rubber spring 5 to form a new micro-perforated corrugated-honeycomb metamaterial plate structure based on the local resonance mechanism to impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com