High-hardness artificial stone

A technology of artificial stone and high hardness, applied in the field of artificial stone, can solve the problems of high brittleness and easy cracking of artificial stone, and achieve the effects of increasing tensile strength, improving dispersibility, increasing hydrophilicity and wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

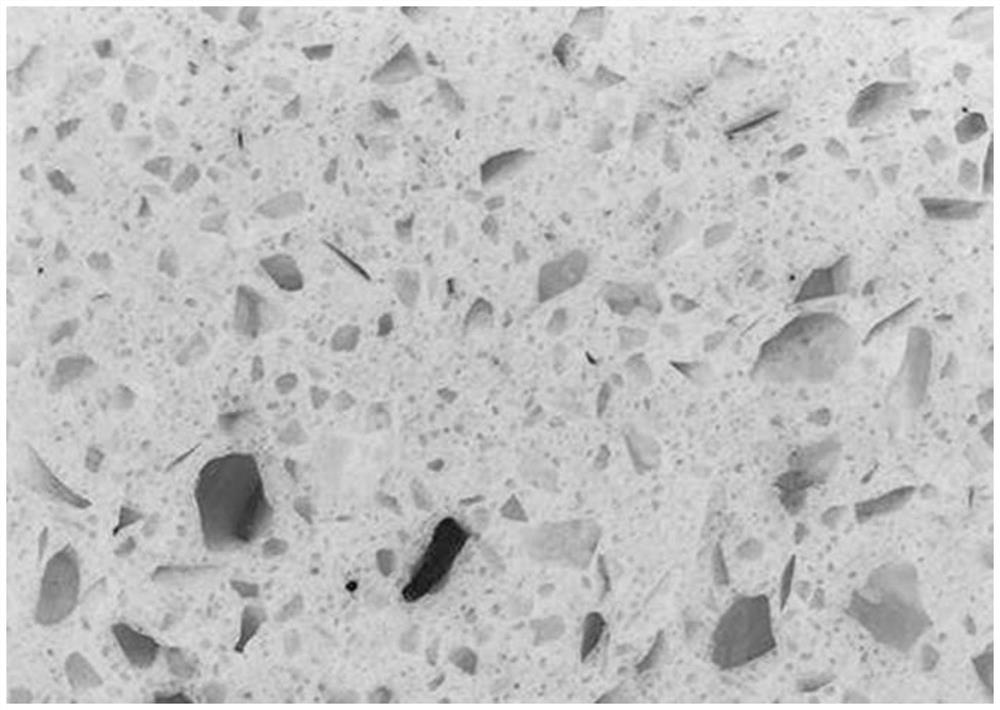

Image

Examples

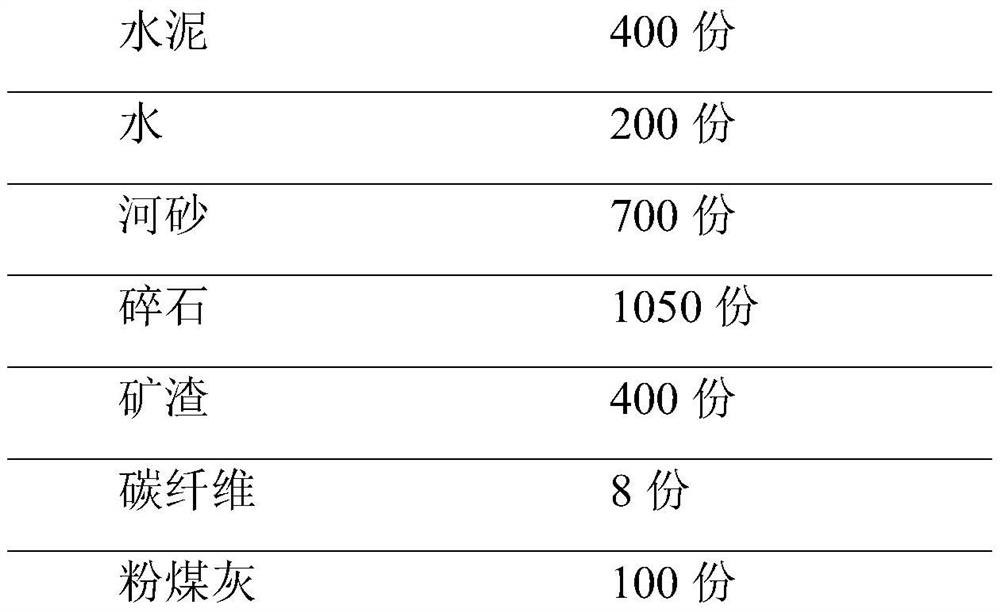

Embodiment 1

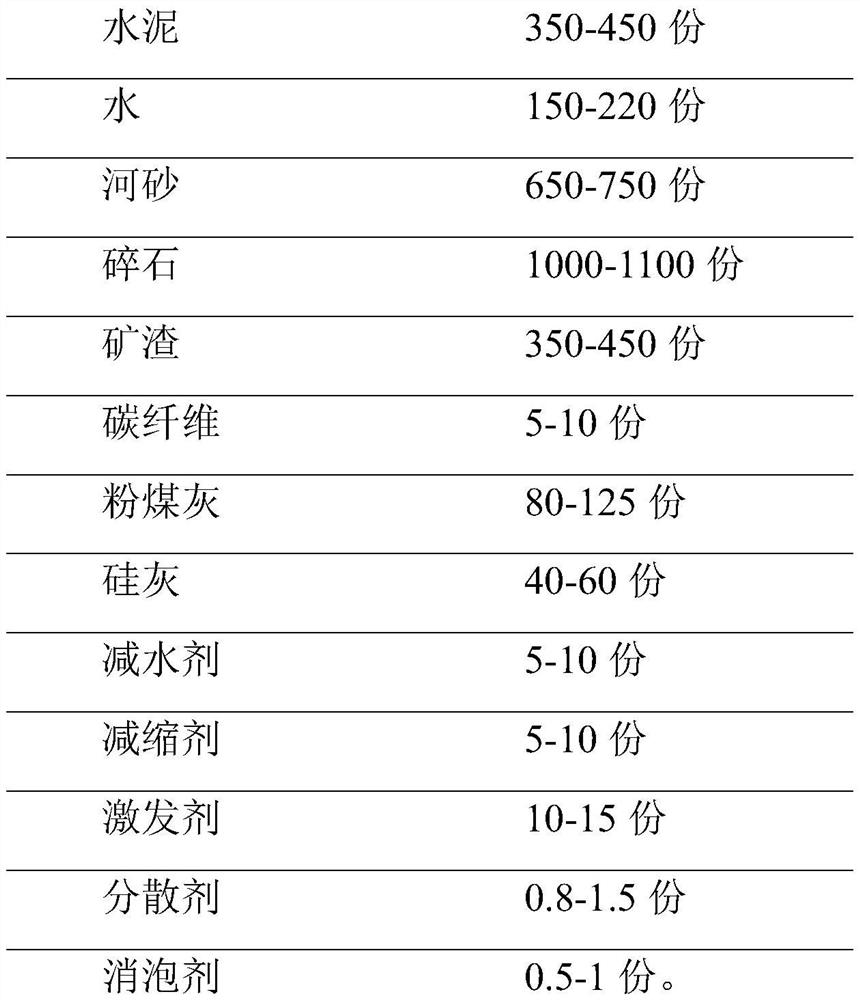

[0023] The invention discloses a high-hardness artificial stone, which is made of raw materials including the following parts by weight:

[0024]

[0025]

[0026] Wherein, the cement is P.W42.5 white cement or P.II42.5R ordinary Portland cement. In the silica fume, the content of SiO2 is 92.3%, the content of Al2O3 is 0.66%, and the content of CaO is 0.31%. In the slag, the content of CaO is 38.32%, the content of SiO2 is 31.12%, and the content of Al2O3 is 13.86%. The water reducer is a polycarboxylate water reducer with a solid content of 20%-40%. The particle size of the river sand is less than 0.63mm. The gravel is artificial gravel mainly composed of granite and basalt with good grading, dense and hard, and rough surface, with a particle size range of 5-20mm, and is graded according to continuous particle size. The dispersant is selected from hydroxypropyl methylcellulose, the density is 1.39g / cm3, the passing rate of 100 mesh is greater than 98.5%, the carboniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com