A kind of water-based glass colored jade sand material and preparation method thereof

A technology of glass and color, applied in the field of glass colored jade sand material and its preparation, water-based glass colored jade sand material and its preparation, to achieve the effect of coating energy saving, material environmental protection, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The water-based glass colored jade sand material of this embodiment includes component A and component B, and the mass ratio of component A to component B is 1:6.

[0075] Among them, in terms of mass percentage, component A is composed of 80% of XP2487 hydrophilic aliphatic isocyanate, 15% of N3900 low-viscosity aliphatic isocyanate, and 5% of GF40 isocyanate silane coupling agent.

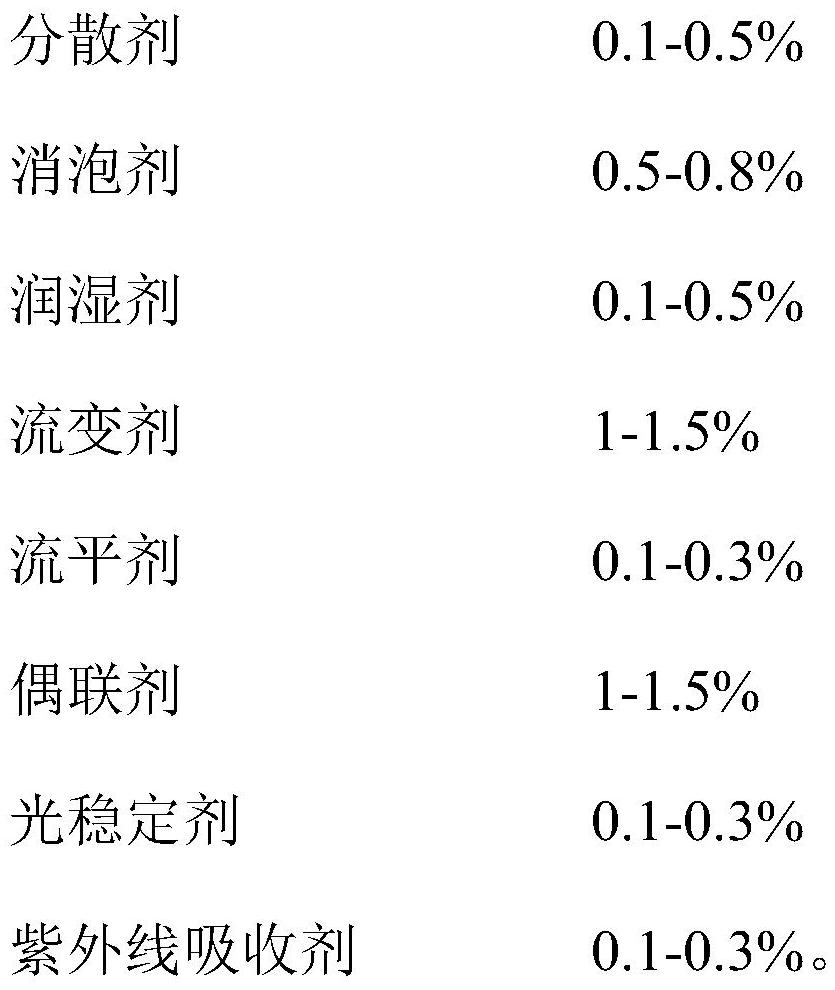

[0076] Among them, in terms of mass percentage, component B consists of 20% of A2695 hydroxyl acrylic dispersion, 10% of U2766 hydroxyl polyurethane dispersion, 10% of EPICLON H502 epoxy resin dispersion, 32.1% of deionized water, 18% of silicon micropowder, silicon dioxide Microsphere 4%, bentonite 0.5%, FX365 polyether copolymer dispersant 0.1%, TEGO845 polysiloxane defoamer 0.6%, W469 silicone wetting agent 0.5%, HX6008 polyurethane rheological agent 1.2%, BYK381 acrylic copolymer It consists of 0.1% logistics agent, 1.5% Z6040 epoxy silane coupling agent, 0.1% TINUVINS292 light stabili...

Embodiment 2

[0088] The water-based glass colored jade sand material of this embodiment includes component A and component B, and the mass ratio of component A to component B is 1:6.

[0089] Among them, in terms of mass percentage, component A is composed of 75% of XP2487 hydrophilic aliphatic isocyanate, 17% of N3900 low-viscosity aliphatic isocyanate, and 8% of GF40 isocyanate silane coupling agent.

[0090] Among them, in terms of mass percentage, component B consists of 27% of A2695 hydroxyl acrylic dispersion, 11% of U2766 hydroxyl polyurethane dispersion, 8% of EPICLON H502 epoxy resin dispersion, 24% of deionized water, 16% of silicon micropowder, silicon dioxide Microspheres 8%, bentonite 0.2%, FX365 polyether copolymer dispersant 0.5%, TEGO845 polysiloxane defoamer 0.8%, W469 silicone wetting agent 0.3%, HX6008 polyurethane rheology agent 1.5%, BYK381 acrylic copolymer It consists of 0.3% logistics agent, 1.3% Z6040 epoxy silane coupling agent, 0.3% TINUVINS292 light stabilizer, ...

Embodiment 3

[0102] The water-based glass colored jade sand material of this embodiment includes component A and component B, and the mass ratio of component A to component B is 1:6.

[0103] Among them, in terms of mass percentage, component A is composed of 85% of XP2487 hydrophilic aliphatic isocyanate, 10% of N3900 low-viscosity aliphatic isocyanate, and 5% of GF40 isocyanate silane coupling agent.

[0104]Among them, in terms of mass percentage, component B consists of 40% of A2695 hydroxyl acrylic dispersion, 10% of U2766 hydroxyl polyurethane dispersion, 5% of EPICLON H502 epoxy resin dispersion, 28.6% of deionized water, 10% of silicon micropowder, silicon dioxide Microsphere 2%, bentonite 0.3%, FX365 polyether copolymer dispersant 0.3%, TEGO845 polysiloxane defoamer 0.6%, W469 silicone wetting agent 0.1%, HX6008 polyurethane rheological agent 1%, BYK381 acrylic copolymer It consists of 0.2% logistics agent, 1% Z6040 epoxy silane coupling agent, 0.2% TINUVINS292 light stabilizer, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com