Method for preparing biogas through anaerobic digestion of sludge and obtained biogas

An anaerobic digestion and sludge technology, applied in biological sludge treatment, pyrolysis treatment of sludge, special forms of dry distillation, etc., can solve the problems of incomplete degradation of organic matter, long anaerobic digestion cycle, and large equipment area. , to achieve the effect of promoting circular economy, realizing resource utilization and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Wherein, the preparation method of described biochar comprises:

[0030] (1) Digesting the sludge raw material under airtight and anaerobic conditions to obtain the first digested sludge;

[0031] (2) crushing the first digested sludge after filtering and drying to obtain the second digested sludge;

[0032] (3) obtaining the first product after pyrolyzing the second digested sludge;

[0033] (4) After boiling the first product in an acid solution, the pH is adjusted to be neutral, and the solid obtained after drying is the biochar.

[0034] Wherein, the sludge raw material in step (1) includes fresh sludge and inoculated sludge or the sludge raw material includes fresh sludge, inoculated sludge and biochar.

[0035] Wherein, the mass ratio of fresh sludge and inoculated sludge described in step (1) is 1: (0.15 to 0.25);

[0036] Wherein, the temperature of the digestion reaction described in step (1) is 30 to 40 degrees Celsius; the digestion time is 18 to 23 days; ...

Embodiment 1

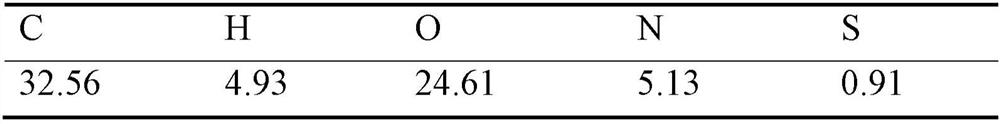

[0055] (1) The sludge used in this example comes from a sewage treatment plant in Tianjin. The moisture content of the sludge is 90.23%. After adjusting the moisture content to 95.0%, an anaerobic digestion experiment is carried out. The elemental analysis and industrial analysis of the sludge are as follows :

[0056] Table 1 elemental analysis (%)

[0057]

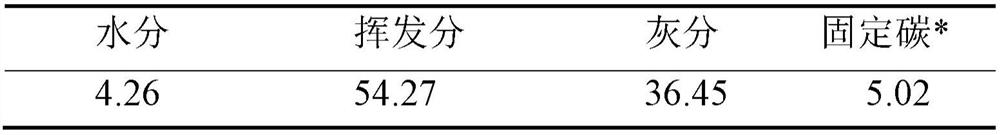

[0058] Table 2 Industrial Analysis (%)

[0059]

[0060] Among them, the fixed carbon* in Table 2 is calculated by subtraction method

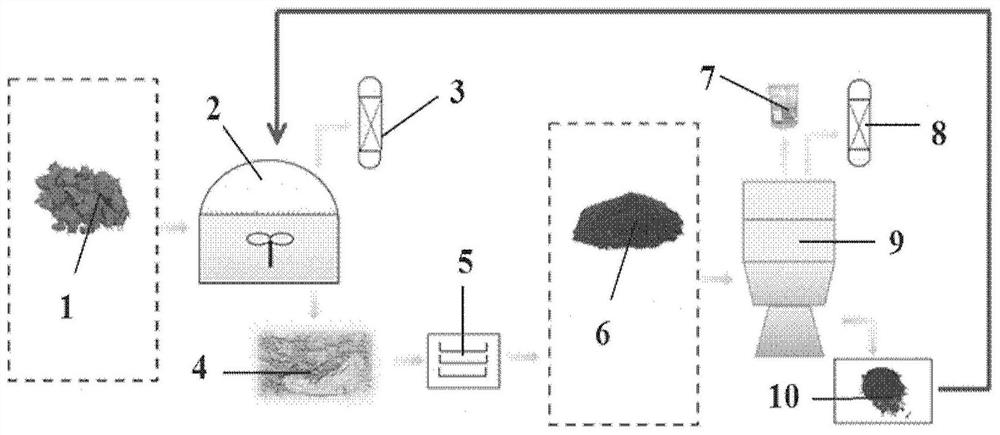

[0061] (2) In this embodiment, the temperature of anaerobic digestion is 36 degrees Celsius, the volume of the digestion reactor is 1000 ml, the volume ratio is 0.8, and the inoculated sludge ratio is 0.2. Such as figure 1 As shown, the specific operation steps are as follows:

[0062] ① Take 640ml of fresh sludge 1 and 160ml of inoculated sludge into anaerobic digestion reactor 2 respectively, put a rotor into it, and pass nitrogen gas for 5 minutes to remove oxygen in the hea...

Embodiment 2

[0074] The pyrolysis and anaerobic digestion systems and raw materials used in this example are the same as those in Example 1, and will not be described in detail. The difference is that the number of digestion days in this embodiment is 5 days.

[0075] This embodiment is carried out for 5 days, the gas production of the experimental group is 171.05 milliliters, the gas production of the blank group is 136.9 milliliters, the gas production of the experimental group has increased by 24.94% relative to the blank group; the methane content of the biogas of the experimental group is 39.33%, and the methane in the biogas of the blank group The content is 34.23%, and the biogas methane content of the experimental group has increased by 14.99% compared with the blank group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com