Sealed waterproof jacking mechanism of movable bearing seat

A mobile bearing seat, waterproof technology, applied to the device for fixing the grinding wheel, the components of the grinding machine tool, metal processing equipment, etc., can solve the problems of slider wear, environmental pollution, loss of connection mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

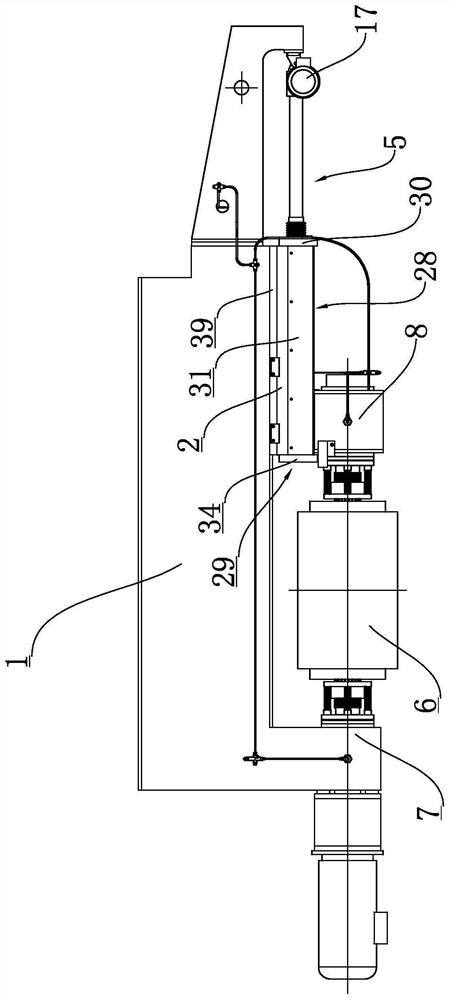

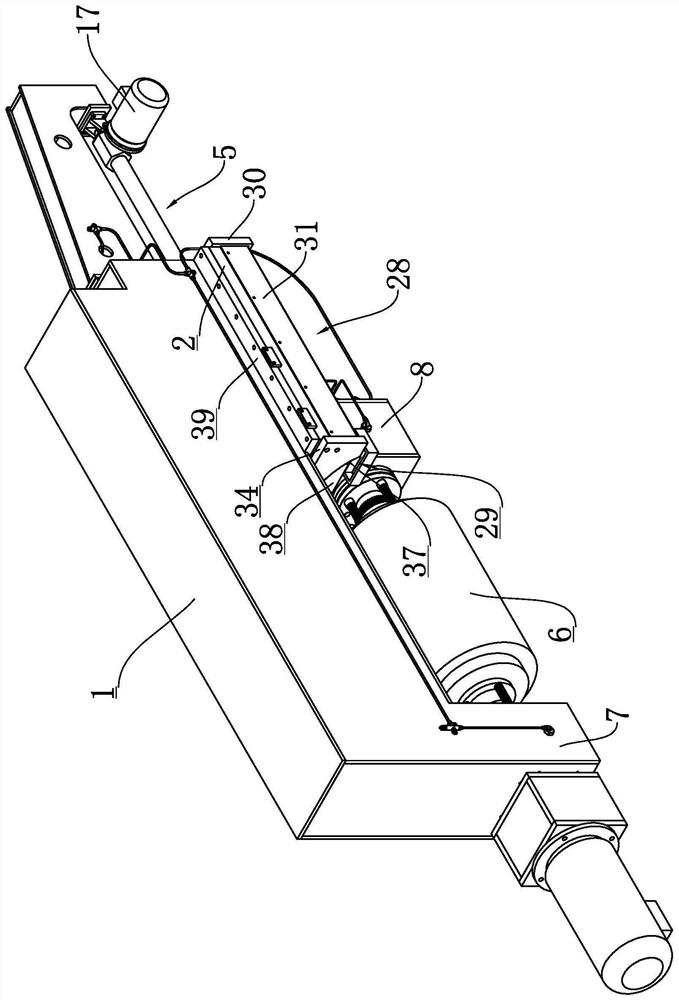

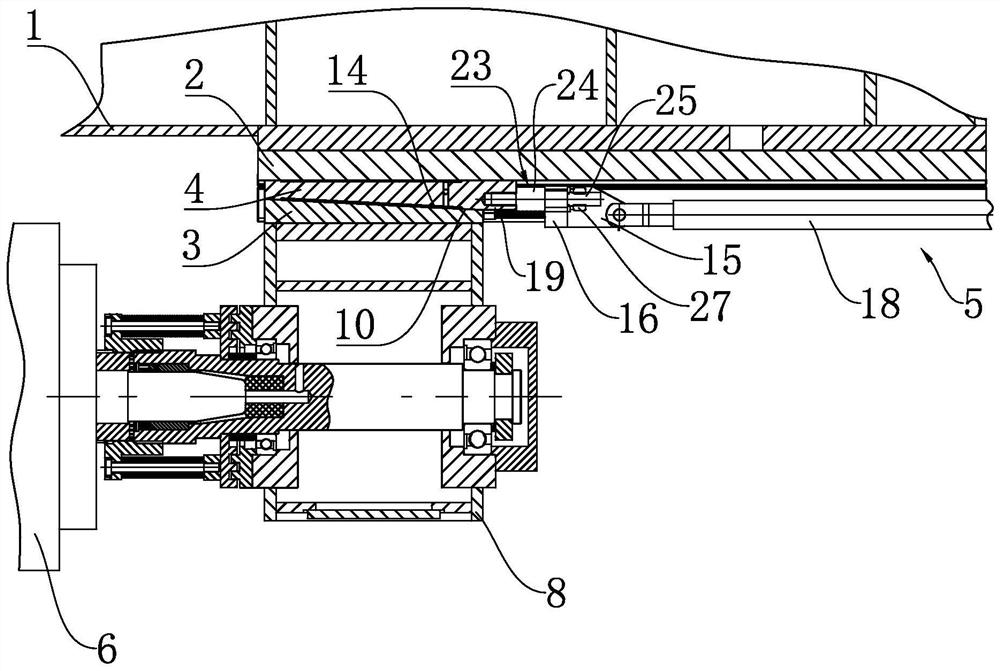

[0049] Such as Figure 1-14 As shown, the present invention provides a sealed and waterproof jacking mechanism for a mobile bearing seat, which includes a work roll seat 1 , a slide rail seat 2 , a slider 3 , a locking block 4 and an elastic driving mechanism 5 .

[0050] The work roll base 1 is used to install the descaling roller 6 for rust removal, and the two ends of the work roll base 1 are respectively provided with a fixed bearing seat 7 and a movable bearing seat 8; When the roll 6 is worn to the extent that the derusting effect cannot meet the processing requirements, a new scale-breaking roll 6 needs to be replaced. The working roll base 1 separates or engages the scale-breaking roll 6 by moving the bearing seat 8 away from or approaching the fixed bearing seat 7 to achieve The purpose of changing rolls.

[0051] Specifically, the slide rail seat 2 is fixedly connected to the bottom of the work roll seat 1, and a chute is provided under the slide rail seat 2. The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com