Repairing equipment for roller

A kind of equipment and sleeve technology, applied in the field of roller repair equipment, can solve the problems of poor grinding efficiency and effect, difficult to guarantee accuracy, and cumbersome adjustment of grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

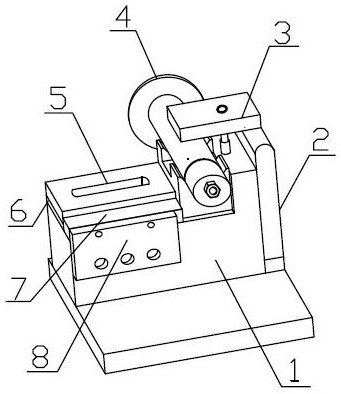

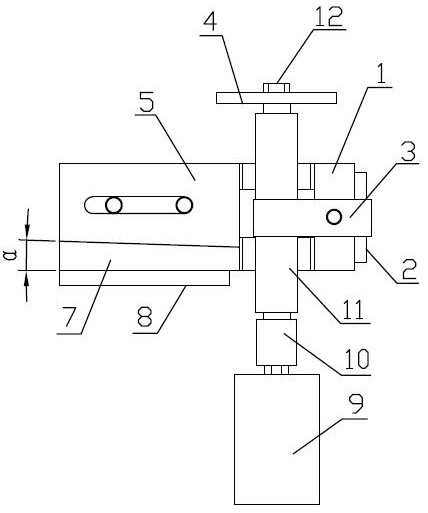

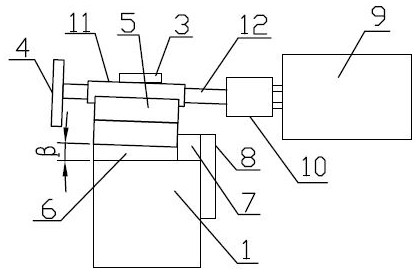

[0020] Such as Figure 1-Figure 3 As shown, a repairing device for a roller includes a driving device 9, a sleeve 11 and a transmission shaft 12, the transmission shaft 12 passes through the sleeve 11 and is rotatably connected with the sleeve 11, and the transmission shaft 12 One end of one end is connected with the drive device 9 through the elastic coupling 10, and the drive device 9 is preferably a motor. It also includes the above-mentioned clamping tool, the clamping tool is used to clamp the sleeve 11, the sleeve 11 and the clamping tool are reliably clamped, the driving device 9 drives the transmission shaft 12 to rotate, and drives the roller 4 to rotate, Perform grinding operations.

[0021] Such as Figure 1-Figure 4 As shown, the clamping tool includes a base 1 and a mounting base 4, the mounting base 4 includes a clamping part 53 and an adjustment part 51, and the adjustment part 51 is located on the side of the clamping part 53, and The adjustment part 51 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com