Preparation method of vitamin-B buccal tablets and chewable tablets

A technology of B vitamins and chewable tablets, which is applied in the direction of food science, can solve the problems of large amount of sweeteners, heavy bitterness, and low content of B vitamins, and achieve the effect of improving the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

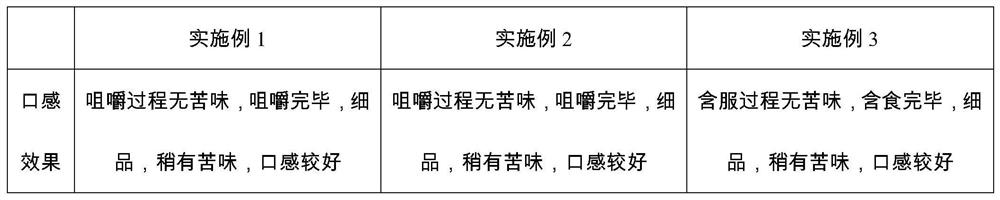

example 1

[0047]The content of each component per 1000 tablets is: thiamine hydrochloride 2g, riboflavin 2g, pyridoxine hydrochloride 2g, vitamin B12 (1%) 0.2g, nicotinamide 50g, folic acid 0.4g, biotin (1%) ) 8g, D-calcium pantothenate 17g, sorbitol 658.4g, anhydrous citric acid 24g, magnesium stearate 16g, hypromellose 10g, aspartame 2g, yellow peach essence 8g;

[0048] Step 1: Preparation of Niacinamide Sustained Release Granules

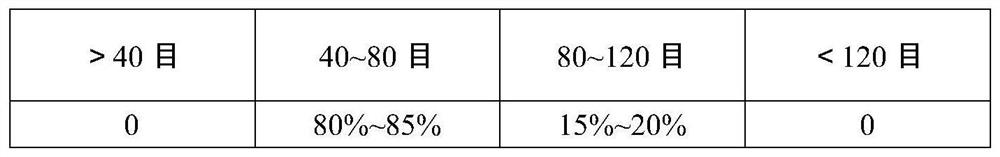

[0049] 1) Weigh 100g of niacinamide, 354g of sorbitol, 24g of anhydrous citric acid, 20g of hypromellose, and 2g of aspartame after passing through an 80-mesh sieve, and place them in a wet mixing granulator with stirring speed Set it to 600rpm, set the chopping speed to 1200rpm, mix for 5 minutes, then add 70% ethanol as a wetting agent, the amount added can completely wet the mixture, set the stirring speed to 600rpm, set the chopping speed to 1200rpm, and granulate Set the time to 100S, then set the drying temperature of the blast drying oven to 40°C,...

example 2

[0061] The content of each component per 1000 tablets is: thiamine hydrochloride 8g, riboflavin 7g, pyridoxine hydrochloride 8g, vitamin B12 (1%) 0.2g, nicotinamide 36g, folic acid 0.4g, biotin (1%) ) 8g, D-calcium pantothenate 14g, sorbitol 883.5g, magnesium stearate 20g, hypromellose 5.4g, aspartame 1.5g, corn essence 8g;

[0062] Step 1: Preparation of Niacinamide Sustained Release Granules

[0063] 1) Dissolve 1g of aspartame in 10g of 70% ethanol solution to prepare aspartame 70% ethanol solution for later use.

[0064] 2) Weigh 72g of niacinamide, 176.2g of sorbitol, and 10.8g of hypromellose after passing through an 80-mesh sieve, and place them in a wet mixing granulator, set the stirring speed to 600rpm, and the chopping speed to 1200rpm, mix The time is 5 minutes, add aspartame 70% ethanol solution, the stirring speed is set to 600rpm, the chopping speed is 1200rpm, the granulation time is 100S, and then dried in a blast drying oven at 40°C until the moisture conten...

example 3

[0076] The content of each component per 1000 tablets is: 7g of thiamine hydrochloride, 7g of riboflavin, 7g of pyridoxine hydrochloride, 0.2g of vitamin B12 (1%), 40g of nicotinamide, 0.4g of folic acid, biotin (1%) ) 4g, D-calcium pantothenate 12g, sorbitol 1086.9g, magnesium stearate 24g, hypromellose 2g, aspartame 1.5g, wheat flavor 8g.

[0077] Step 1: Preparation of Niacinamide Sustained Release Granules

[0078] 1) Dissolve 4g of hypromellose in 40g of 85% ethanol solution to prepare hypromellose 85% ethanol solution for later use;

[0079] 2) Weigh 80g of niacinamide and 316g of sorbitol after passing through an 80-mesh sieve, and place them in the wet mixing granulator in turn, set the stirring speed at 600rpm, the chopping speed at 1200rpm, and the mixing time for 5min, then add hydroxypropyl Methyl cellulose 85% ethanol solution, the stirring speed is set to 600rpm, the chopping speed is 1200rpm, the granulation time is 100S, and then dried in a blast drying oven a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com