Gallium nitride transistor for AC/DC and manufacturing method thereof

A transistor and gallium nitride technology, applied in the field of AC/DC gallium nitride transistors and their manufacturing, can solve the problems affecting the performance and service life of gallium nitride transistors, the poor heat dissipation performance of gallium nitride transistors, and the increase of gallium nitride transistors. Transistor cost and other issues, to achieve the effect of optimizing performance and service life, strong practicability, and reducing loss and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

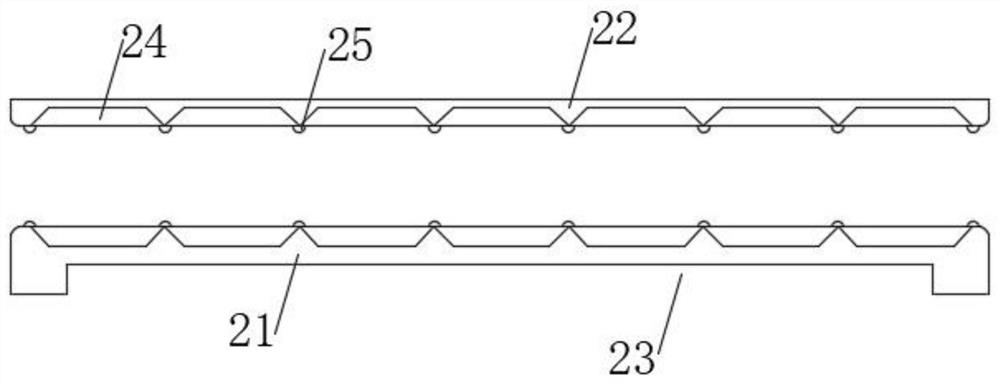

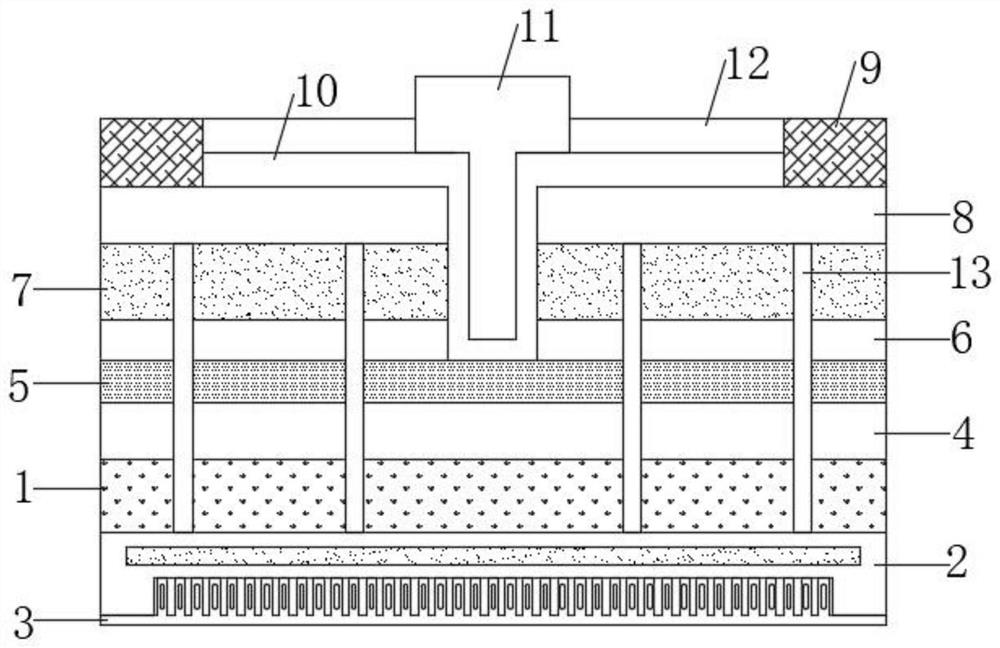

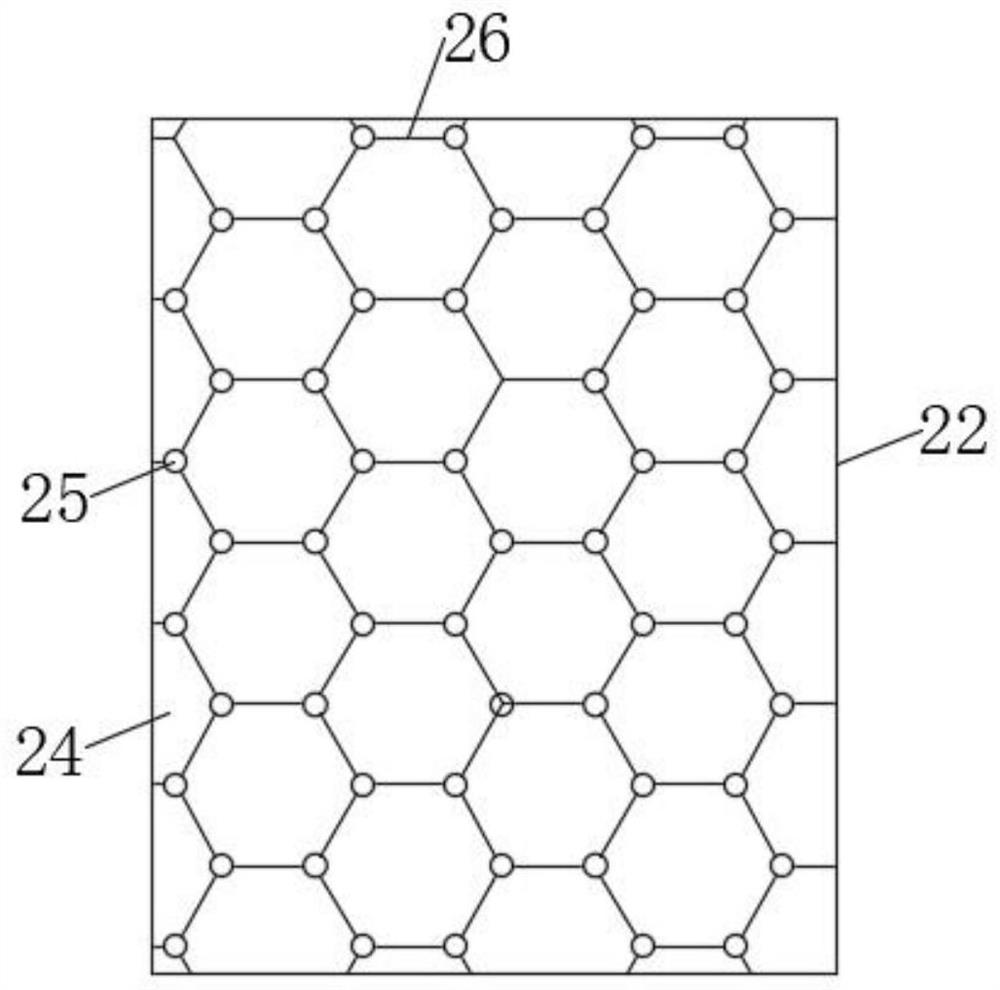

[0026] like Figure 1-4 As shown, this specific embodiment adopts the following technical solution: a gallium nitride transistor for AC / DC, including a nucleation layer 1 and a substrate layer 2, the bottom of the nucleation layer 1 is provided with a substrate layer 2, so The substrate layer 2 is provided with a fluid heat dissipation structure, the bottom of the substrate layer 2 is fixedly installed with a heat sink 3, and the top of the nucleation layer 1 is provided with a conductive buffer layer 4, and the conductive buffer layer 4 is far away from the nucleation layer. One side of 1 is provided with a drift layer 5, and the side of the drift layer 5 away from the conductive buffer layer 4 is provided with an electron blocking layer 6, and the side of the electron blocking layer 6 away from the conductive buffer layer 4 is provided with a channel layer 7 , the side of the channel layer 7 away from the electron blocking layer 6 is provided with a barrier layer 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com