Speed reduction clutch device of mechanical fertilizer applicator

A technology of clutch device and fertilizer applicator, which is applied in the direction of fertilization device, mechanical drive clutch, clutch, etc. It can solve the problems of affecting the service life of the mechanism, sticking of crops and weeds, and poor working reliability, so as to save the cost of parts and reduce the weight , the effect of reducing the strength requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

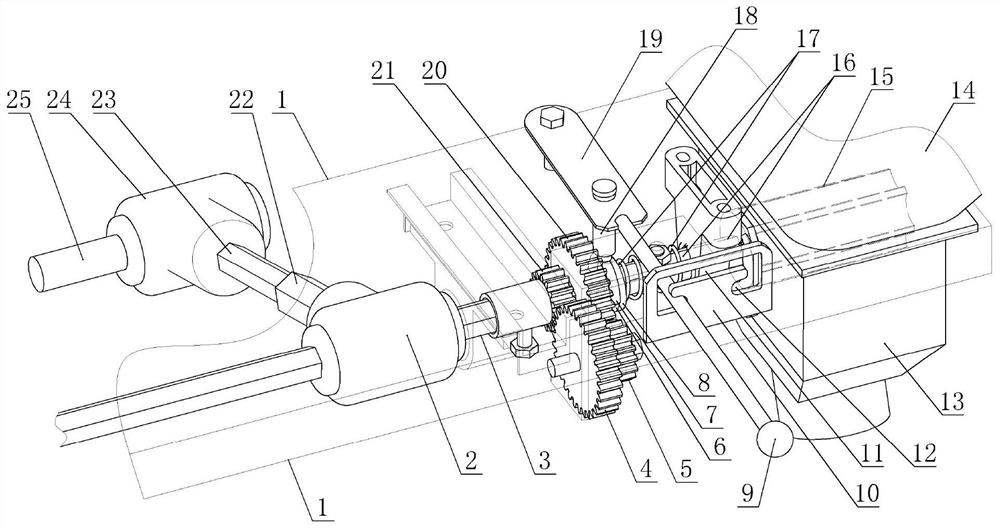

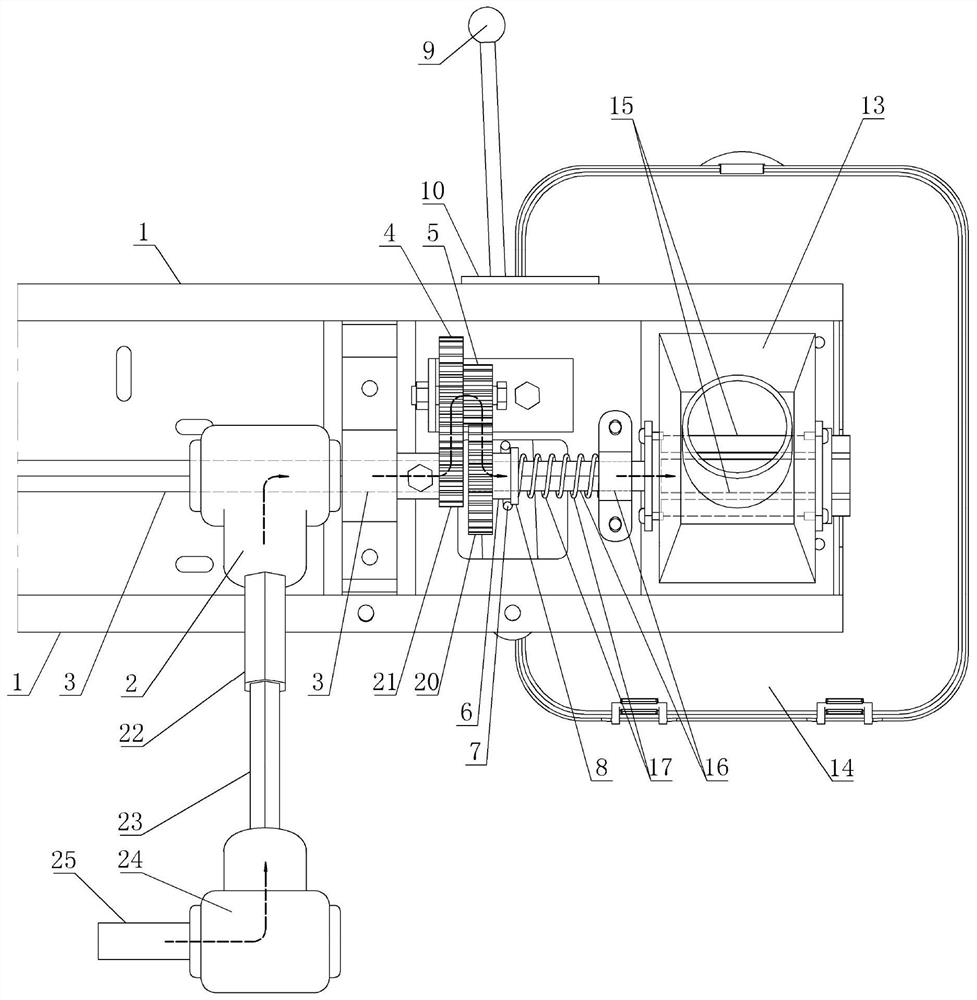

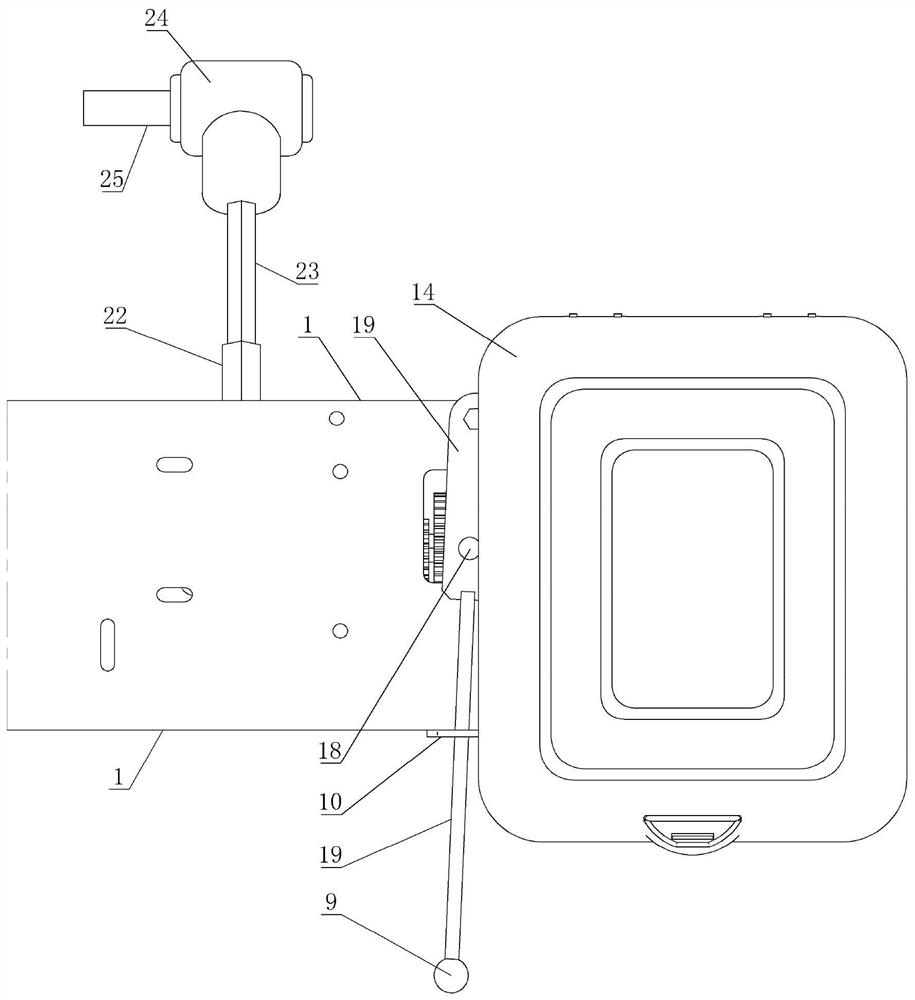

[0030] Mechanical fertilizer applicator deceleration clutch device, such as Figure 1 to Figure 5 As shown, it comprises a support 1 in the fertilizer applicator, a main reversing machine 2 and a fertilizer bucket 14 are housed on the support, and the main reversing machine is provided with a power output shaft 3 of the main reversing machine and a power input shaft 22 of the main reversing machine , the fertilizer outlet of the fertilizer hopper is equipped with a wheeled fertilization mechanism 13, a fertilizer wheel 15 that is connected in rotation is housed in the wheeled fertilizer mechanism, the first reduction gear 21 is fixed on the power output shaft of the main commutator, and the bracket Rotate the connected intermediate gear 4 and the fat wheel shaft 16, the intermediate gear is engaged with the first reduction gear, and the second reduction gear 5 is fixed on the intermediate gear; one end of the fat wheel shaft is fixedly connected with the fat wheel, and the clut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com