Gasoline fraction desulfurization method, method for producing low-sulfur gasoline and reaction system

A gasoline fraction and reaction system technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of small adjustable range of reaction conditions and reduced operation flexibility of the device, so as to save equipment investment and save energy. Energy consumption and equipment investment, the effect of suppressing the generation of regenerated mercaptan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

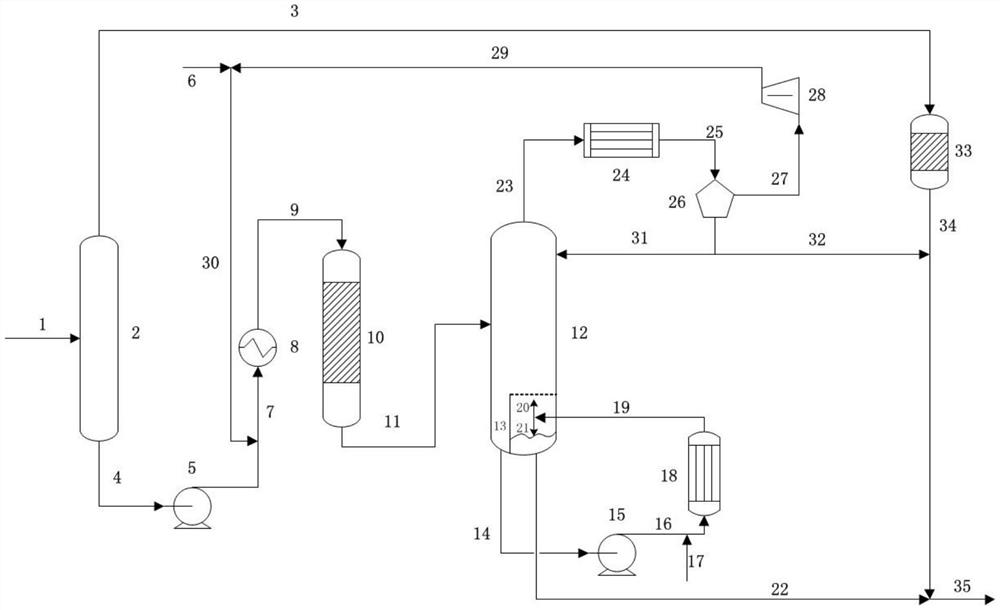

[0075] Embodiment 1 adopts the accessory provided by the present invention figure 1 In the flow chart of the method for producing low-sulfur gasoline shown, the raw materials used are the same as those of the comparative example, and the primary desulfurization reaction conditions of the first reactor and the catalyst used are the same as those of the comparative example 1. The reaction product of the first reactor is heated to 180°C and then enters the stripping tower. The operating pressure of the stripping tower is 1.6MPa, the temperature at the top of the tower is 40°C, and the temperature at the bottom of the tower is 180°C. 8 pieces. The second reactor is a heat exchange reactor with a shell and tube structure. The second hydrodesulfurization catalyst is filled in the tube side of the reactor. The preparation method of the second hydrodesulfurization catalyst refers to the published patent CN104437518A. Into medium pressure steam heating. The operating conditions of th...

Embodiment 2

[0077] Embodiment 2 adopts the method for producing low-sulfur gasoline according to the present invention, the raw materials used are the same as those of the comparative example, the cutting temperature of the whole distillate gasoline is 70° C., and the steps and conditions of the alkali washing desulfurization of the cut light gasoline fraction are the same as those of the comparative example 1. Gasoline fraction and hydrogen by volume ratio 400Nm 3 / m 3 After mixing, it is heated to 280°C by a heat exchanger and a heating furnace and enters the first reactor. The operating conditions are: reaction pressure 1.8MPa, and the volumetric space velocity of the feed liquid is 6h -1 . The reaction product of the first reactor is heated to 180°C and then enters the stripping tower. The operating pressure of the stripping tower is 1.6MPa, the temperature at the top of the tower is 40°C, and the temperature at the bottom of the tower is 185°C. 8 pieces. The secondary desulfurizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com