Preparation method of low-rank coal-based superplasticizer

A high-efficiency water-reducing agent and low-rank coal technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of complex synthesis process and high cost, and achieve high yield, low cost, and high technological cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

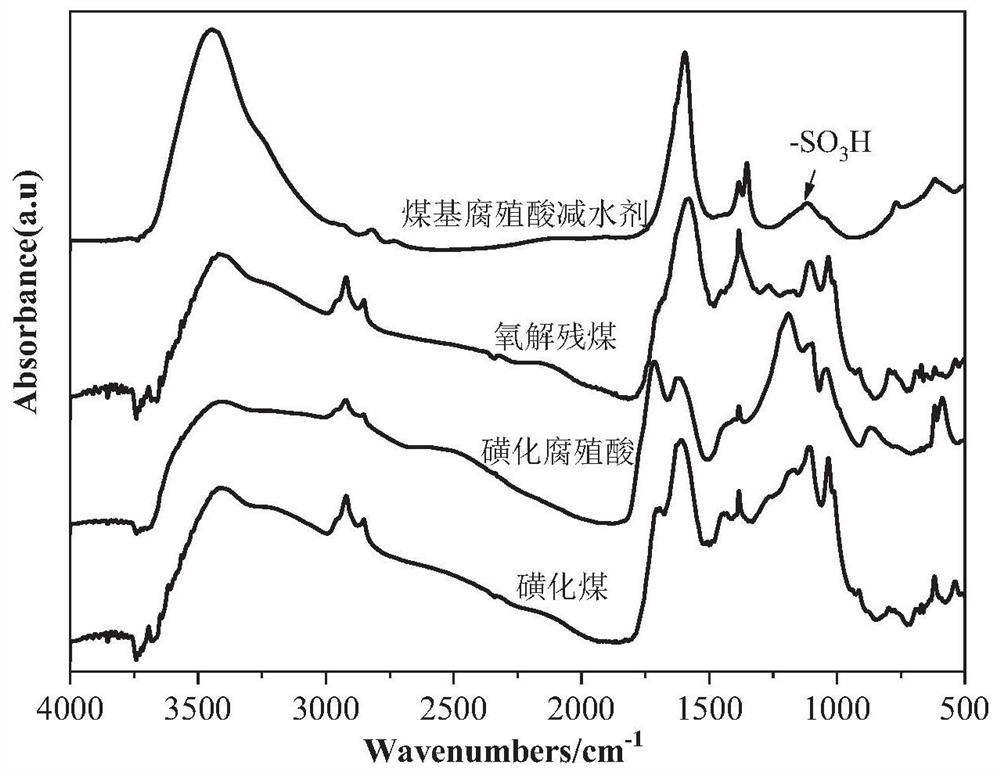

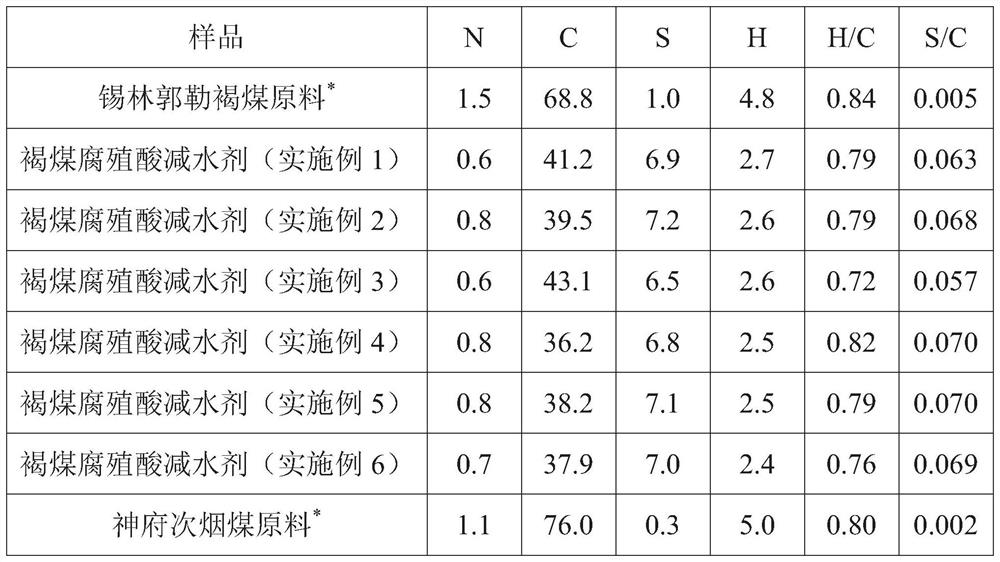

Embodiment 1

[0029] (1) Sulfonation of coal: add 120ml H 2 O. 24g NaHSO 3 , 0.4g FeSO 4, 4ml of 1mol / L dilute sulfuric acid, stir and dissolve, add 20g of 100 mesh dry Xilin Gol lignite, and mix well. Then, add 1.5% H2 dropwise to the reactor at room temperature 2 o 2 Solution 240ml, stirring while adding. After the dropwise addition, the stirring reaction was continued for 1 h. Then the temperature was raised to 60°C, the reaction was kept for 1 hour, and the heating was stopped. After the reaction kettle is lowered to room temperature, the obtained product is centrifuged, washed with water until the pH of the washing solution is greater than 5, and dried to obtain sulfonated coal. The mass yield of sulfonated coal based on raw coal is 110.6%.

[0030] (2) Oxidative cracking of sulfonated coal: In a 250ml autoclave, add H 2 O 100ml, KOH 5g, and 10g of sulfonated coal prepared in (1), after stirring and mixing evenly, pour into O 2 to 5.0MPa. Then, the stirring was started and th...

Embodiment 2

[0033] (1) Sulfonation of coal: add 120ml H 2 O, 40g Na 2 SO 3 , 0.9g FeSO 4 , 8ml of 1mol / L dilute sulfuric acid, stir and dissolve, add 20g of 100 mesh dry Xilin Gol lignite, and mix well. Then, add 1.5% H2 dropwise to the reactor at room temperature 2 o 2 Solution 240ml, stirring while adding. After the dropwise addition, the stirring reaction was continued for 2 h. Then the temperature was raised to 100°C, the reaction was refluxed for 1 h, and the heating was stopped. After the reaction kettle is lowered to room temperature, the obtained product is centrifuged, washed with water until the pH of the washing solution is greater than 5, and dried to obtain sulfonated coal. The mass yield of sulfonated coal based on raw coal is 112.5%.

[0034] (2) Oxidative cracking of sulfonated coal: In a 250ml autoclave, add H 2 O 150ml, KOH 8g, and 10g of sulfonated coal prepared in (1), after stirring and mixing evenly, pour into O 2 to 3.0MPa. Then, the stirring was started ...

Embodiment 3

[0037] (1) Sulfonation of coal: add 50ml H in 500ml reactor 2 O. 8g NaHSO 3 , 0.6g Fe(NO 3 ) 2 , 2ml of 1mol / L dilute sulfuric acid, stir to dissolve, add 10g of 100 mesh dry Xilin Gol lignite, and mix well. Then, add 0.5% H2 dropwise to the reactor at room temperature 2 o 2 Solution 200ml, stirring while adding. After the dropwise addition, the stirring reaction was continued for 2 h. Then the temperature was raised to 60°C, the reaction was kept for 2 hours, and the heating was stopped. After the reaction kettle is lowered to room temperature, the obtained product is centrifuged, washed with water until the pH of the washing solution is greater than 5, and dried to obtain sulfonated coal. The mass yield of sulfonated coal based on raw coal is 108.2%.

[0038] (2) Oxidative cracking of sulfonated coal: In a 250ml autoclave, add H 2 O 100ml, KOH 2g, and 10g of sulfonated coal prepared in (1), after stirring and mixing evenly, pour into O 2 to 5.0MPa. Then, the stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com