Low formaldehyde melamine resin and its application

A melamine resin and low-formaldehyde technology, applied in the field of melamine resin, can solve the problems of polyurethane foam with strong odor, high energy consumption, and long production cycle of melamine resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. low formaldehyde type melamine resin, its preparation method comprises the following steps:

[0030] (1) Add 1 mol of hexamethylol melamine, 7.5 mol of methanol, 1.5 mol of propylene glycol and 0.5 mol of polyether polyol CHE-204 into the reactor to form material I;

[0031] (2) Under stirring conditions, when the temperature reaches 65°C, add a methanol solution of p-toluenesulfonic acid with a mass percentage of 31.5% to the material I, adjust the pH value of the system to 3.5, and obtain the material II;

[0032] (3) Material II is reacted under normal pressure, the reaction temperature is 90° C., and the reaction time is 2 hours, then triethanolamine is added to adjust the pH value of the system to 8 to form material III;

[0033] (4) Add 0.07mol of urea to material III, and mix uniformly to obtain material IV;

[0034] (5) Carrying out vacuum distillation on material IV to separate small molecular substances in the system, the vacuum distillation temperature is...

Embodiment 2~6

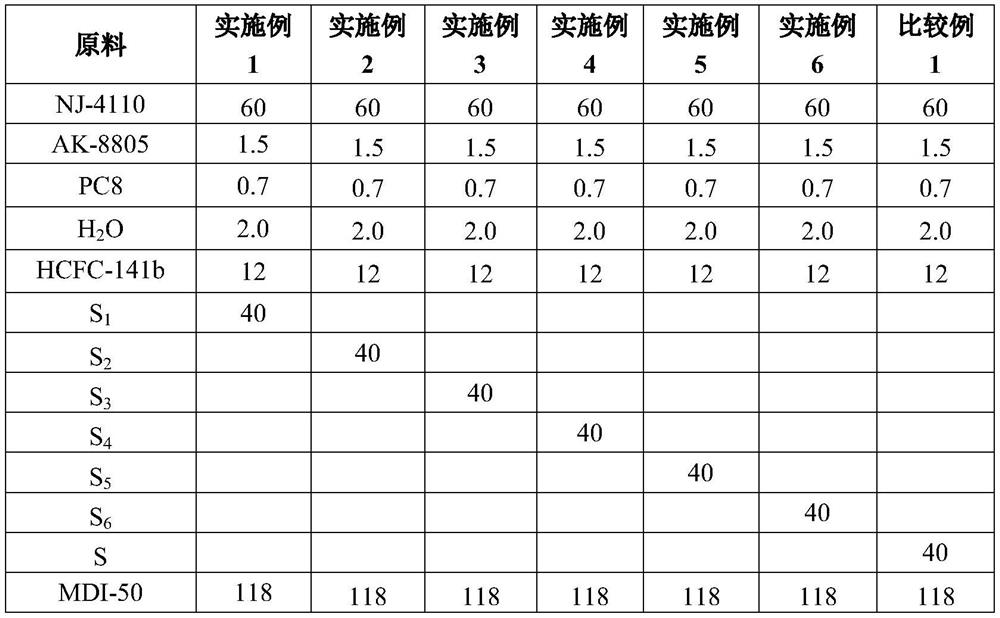

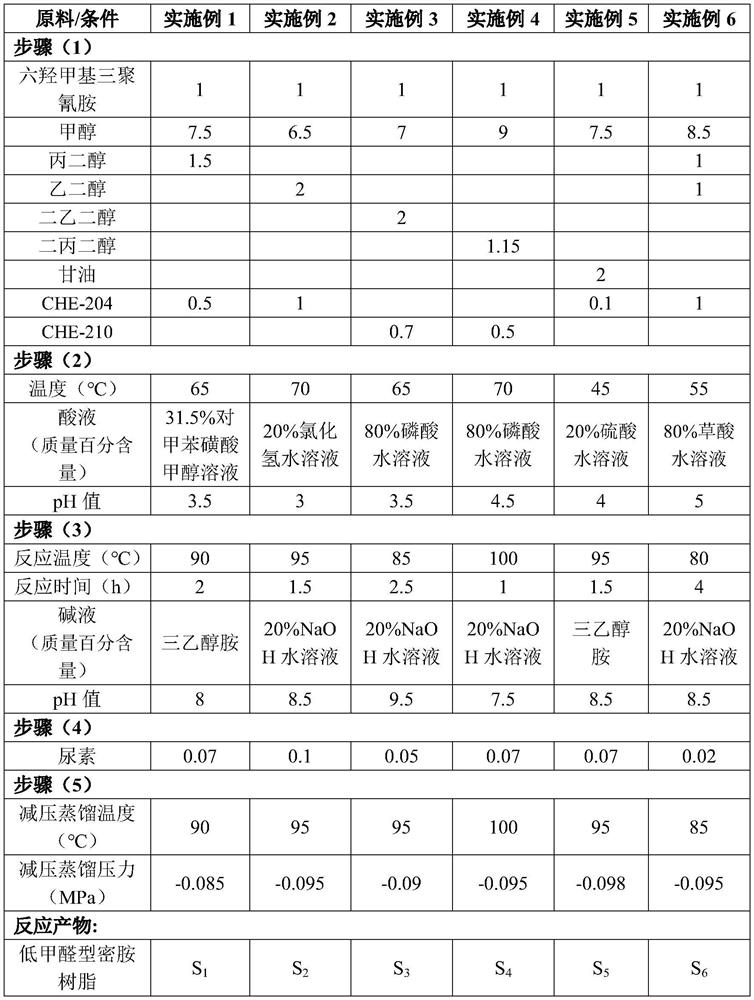

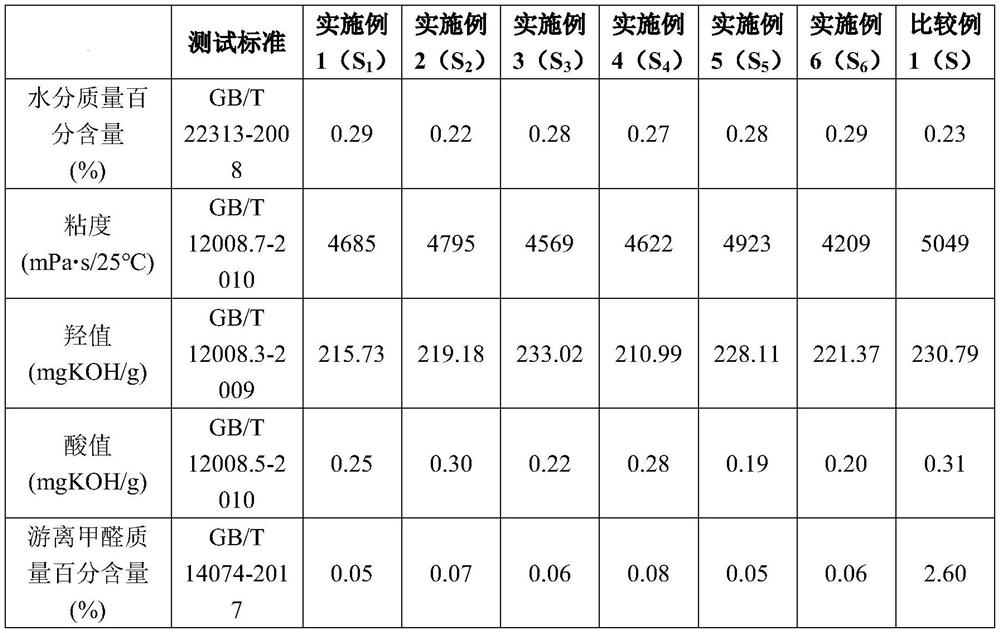

[0046]Embodiment 2~6 is carried out according to each step in embodiment 1, difference is that reaction raw material, raw material ratio, reaction time, reaction temperature, acid solution, lye, and the adjusted pH value are different, see Table 2 specifically; The obtained low-formaldehyde melamine resin was added to the foaming formula of the polyurethane foam according to the mass fraction in Table 1 for foaming, and the performance index data of the prepared polyurethane foam are shown in Table 4.

Embodiment 1~6

[0047] Table 2 The number of moles of raw materials and reaction conditions in the preparation of low-formaldehyde melamine resins in Examples 1 to 6

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com