Oily sewage treatment method, oily sewage treatment system and construction method of oily sewage treatment system

A treatment method and technology of treatment system, which are applied in the field of oily sewage treatment method, treatment system and construction of treatment system, can solve problems such as oily sewage that has not been seen in chemical flooding, reduce viscosity and emulsified oil content, ensure standard treatment, raw materials A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] The construction method of the oily sewage treatment system of the present embodiment is as follows:

[0107] (1) Take 20L of activated sludge from a sewage treatment plant of a petrochemical company in Dalian, with a sedimentation ratio of 26%. The activated sludge is added to the biochemical tank, fed into the chemical flooding oily sewage, and pre-aerated for 12 days; it will account for 15% of the volume of the biochemical tank The supernatant was discharged, supplemented with chemical flooding oily sewage, and exposed for 48 hours. This process was repeated 8 times. The mass ratio of C, N, and P in the biochemical pool was kept at 100:5:0.8, and the water inflow rate was controlled at 2.5m 3 / h, continuous operation for 25 days to complete the acclimatization of activated sludge.

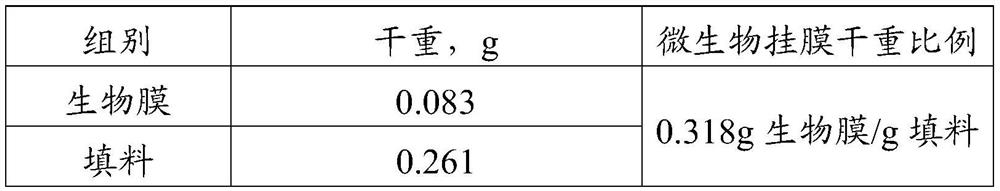

[0108] (2) The domesticated activated sludge is pumped into the upper water distributor and drenched, so that the activated sludge is repeatedly circulated in the simulated container of ...

Embodiment 2

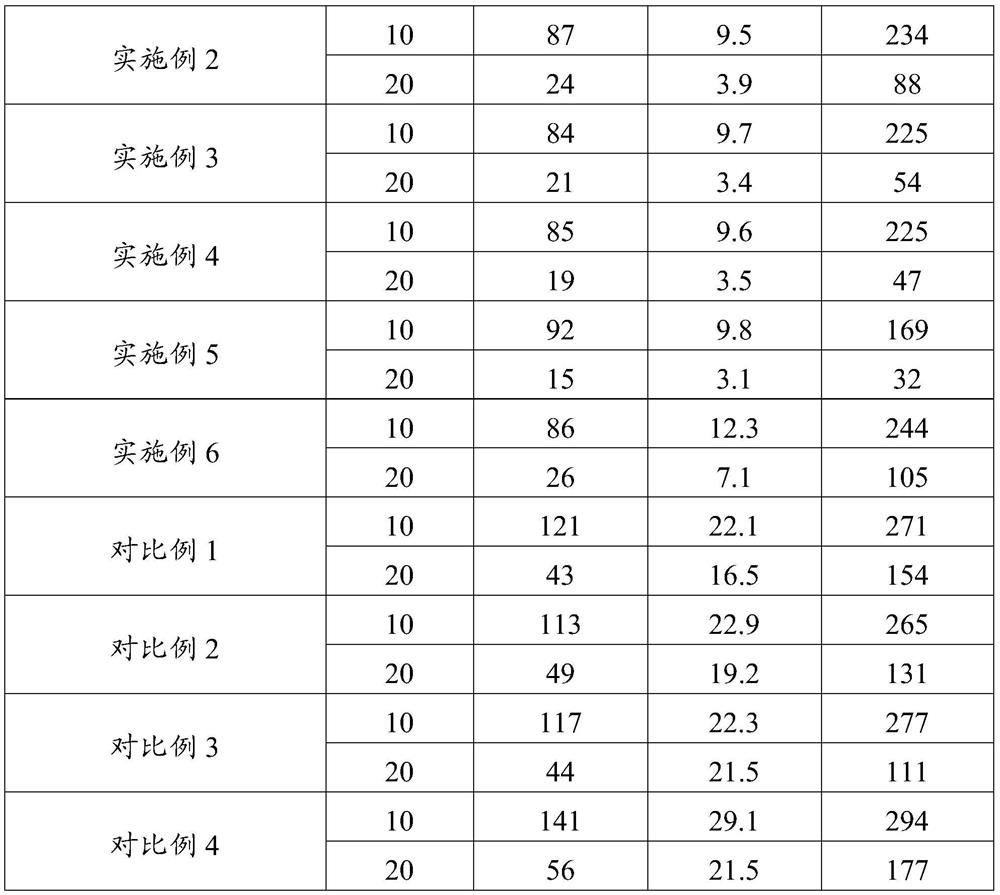

[0114] The difference between the oily sewage treatment system of this embodiment and that of Embodiment 1 is that the inoculum ratio of Bacillus amyloliquefaciens and Bacillus Velesi is 10:1. After the oily sewage treatment system was stabilized, the total number of live bacteria of Bacillus amyloliquefaciens and Bacillus velesi on the biofilm was 1×10 11 piece / m 2 , the ratio of the number of live bacteria of Bacillus amyloliquefaciens and Bacillus Veles is 10:1.

Embodiment 3

[0116] The difference between the oily sewage treatment system of this embodiment and that of Embodiment 1 is that the ratio of the inoculum amounts of Bacillus amyloliquefaciens and Bacillus velesii is 0.5:1. After the oily sewage treatment system was stabilized, the total number of live bacteria of Bacillus amyloliquefaciens and Bacillus velesi on the biofilm was 1×10 12 piece / m 2 , the ratio of the number of live bacteria of Bacillus amyloliquefaciens and Bacillus Veles is 0.6:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

| Oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com