Water electrochemical treatment method for phenolic resin biochemical tail water

A phenolic resin and chemical treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low degradation depth, increased residence time, and large energy consumption. Achieve oxidation ability and long life, improve degradation ability, realize the effect of investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

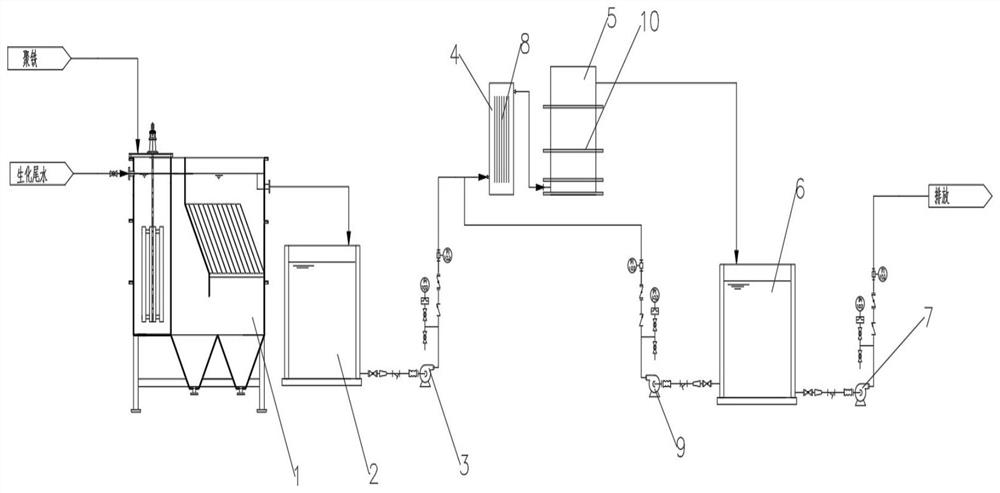

[0038] S1. Obtain the biochemical tail water of phenolic resin, and pretreat the biochemical tail water of phenolic resin. The method of pretreatment is to add alkali to adjust the pH value to 9;

[0039] S2. Inject the biochemical tail water with alkaline adjustment into the inclined tube sedimentation tank 1, then use polyferron with a composition of 10% as a flocculant for flocculation, and stay for 2 hours for precipitation, so as to remove a small amount of oligomers in the biochemical tail water and affect electricity. Substances with oxidation treatment effect can improve subsequent degradation ability and reduce energy consumption;

[0040] S3. Inject the biochemical tail water after the precipitation into the buffer tank 2, and the buffered biochemical tail water enters the BDD-graphene oxidation system through the feed pump 3, and the biochemical tail water enters from the lower part of the BDD oxidation equipment 4, and passes through the first When the middle pole ...

Embodiment 2

[0045] S1. Obtain the biochemical tail water of phenolic resin, and pretreat the biochemical tail water of phenolic resin. The method of pretreatment is to add alkali to adjust the pH value to 9.5;

[0046] S2. Inject the biochemical tail water with alkaline adjustment into the inclined tube sedimentation tank 1, then use 10% polyiron as flocculant for flocculation, and stay for 2 hours for precipitation, so as to remove a small amount of oligomers in the biochemical tail water and affect electricity. Substances with oxidation treatment effect can improve subsequent degradation ability and reduce energy consumption;

[0047] S3. Inject the biochemical tail water after the precipitation into the buffer tank 2, and the buffered biochemical tail water enters the BDD-graphene oxidation system through the feed pump 3, and the biochemical tail water enters from the lower part of the BDD oxidation equipment 4, and passes through the second When the middle pole plate is at 8 positions...

Embodiment 3

[0052] S1. Obtain the biochemical tail water of phenolic resin, and pretreat the biochemical tail water of phenolic resin. The pretreatment method is to add alkali to adjust the pH value to 9;

[0053] S2. Inject the biochemical tail water with alkaline adjustment into the inclined tube sedimentation tank 1, then use 10% polyiron as flocculant for flocculation, and stay for 2 hours for precipitation, so as to remove a small amount of oligomers in the biochemical tail water and affect electricity. Substances with oxidation treatment effect can improve subsequent degradation ability and reduce energy consumption;

[0054] S3. Inject the biochemical tail water after the precipitation into the buffer tank 2, and the buffered biochemical tail water enters the BDD-graphene oxidation system through the feed pump 3, and the biochemical tail water enters from the lower part of the BDD oxidation equipment 4, and passes through the second When the middle pole plate is at 8 positions, adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com