Double-heating-plates sequential hot printing rotary printing machine and textile printing method

A heating plate and double heating technology, which is applied in the field of textile hot printing, can solve the problems of high printing efficiency, large equipment footprint, and serious labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

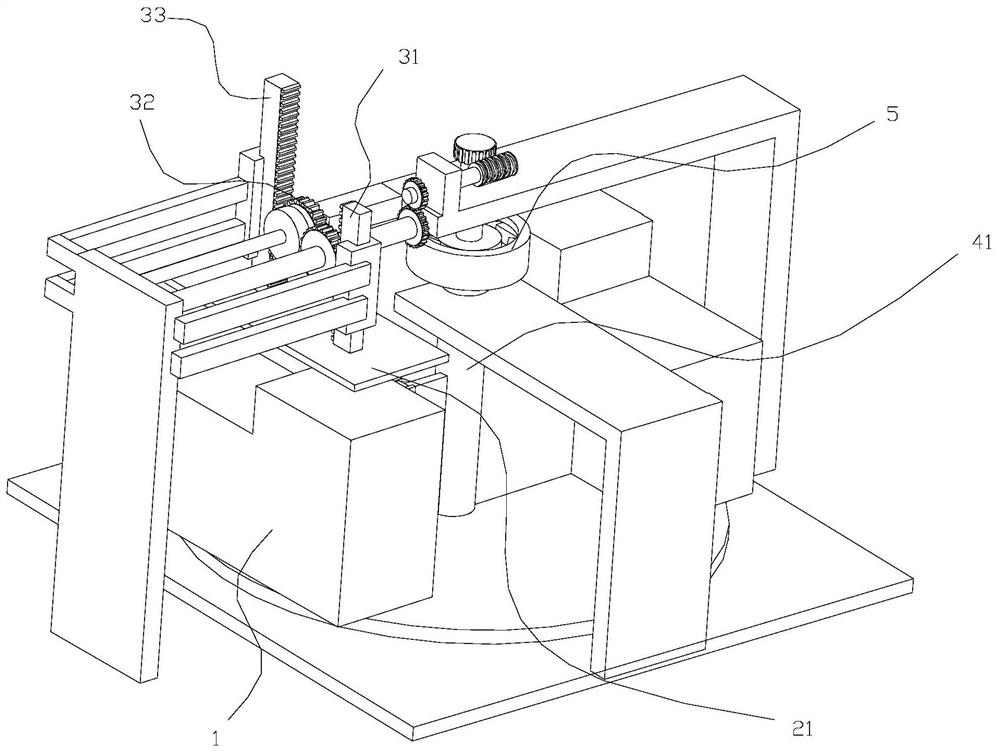

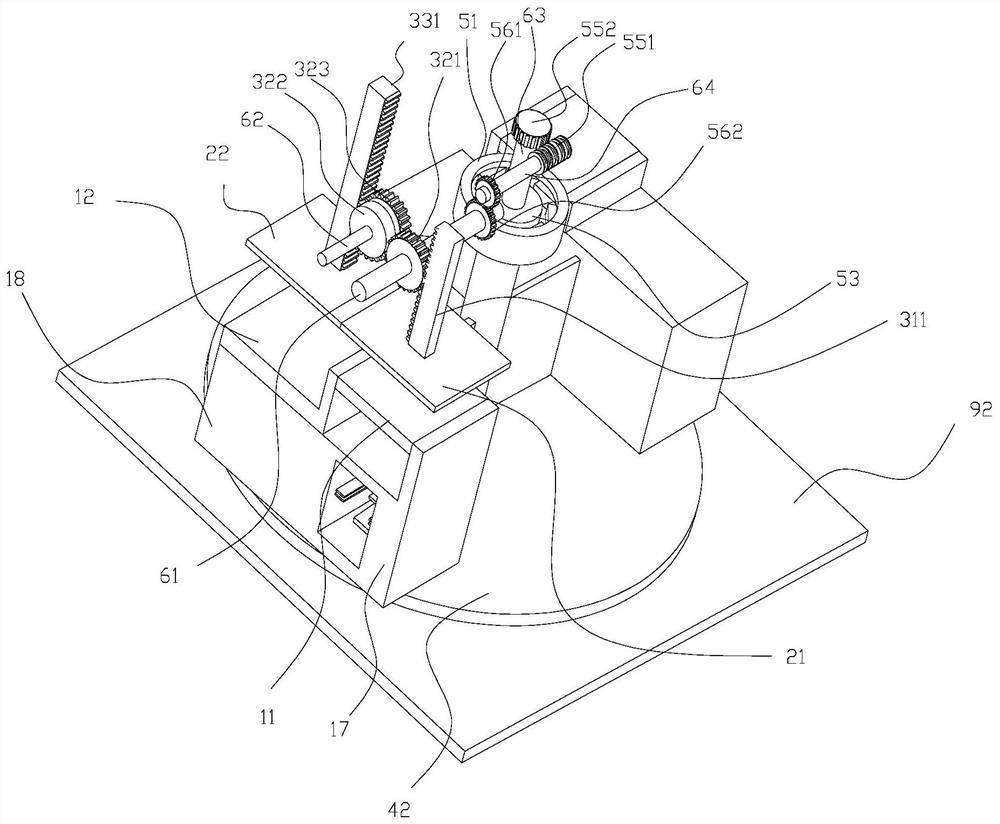

[0057] Such as figure 1 , 2 As shown, this embodiment discloses a rotary printing machine for sequential thermal printing with double heating plates, including a printing plate 1, a heating plate, a first pressing device 31, an intermittent transmission mechanism 32, a second pressing device 33, and a rotating shaft 41 , one-way rotating device 5. The printing plates 1 are connected to the rotating shaft 41, and the rotating shaft 41 can rotate until the two printing plates 1 are opposite to the heating plate alternately.

[0058] The printing plate 1 includes a first printing plate 11 and a second printing plate 12 , the height of the first printing plate 11 is higher than that of the second printing plate 12 . The heating plate includes a first heating plate 21 and a second heating plate 22. When the printing plate 1 is opposite to the heating plate, the first heating plate 21 and the second heating plate 22 are located above the first printing plate 11 and the second prin...

Embodiment 2

[0102] Such as Figure 7-10 As shown, the difference between this embodiment and the above-mentioned embodiments is that the first printing plate 11 and the first printing plate frame 17 are slidably matched in the vertical direction, and the second printing plate 12 can be fixed on the second printing plate frame 18 superior.

[0103] It also includes a pedal driving device, which includes a pedal 71 , a connecting rod 72 , a brake lever 73 , a second elastic member 74 , and a third elastic member 75 . A limited opening slot 171 is provided on the first printing plate frame 17 .

[0104] The upper and lower ends of the connecting rod 72 are respectively hinged with the higher end of the first printing plate 11 and the foot pedal 71, the middle section of the foot pedal 71 is rotatably matched with the first printing plate frame 17, and the second elastic member 74 is The assembly is such that the first printing plate 11 is positioned above the second printing plate 12 .

...

Embodiment 3

[0117] The difference between this embodiment and the above-mentioned embodiments is that: there are unloading storage bins connected under the first printing plate 11 and the second printing plate 12 .

[0118] Such as Figure 11-13 As shown, the top of each printing plate is provided with a first blanking hole 111 and a second blanking hole 112 which are connected up and down. In this embodiment, the first printing plate 11 is taken as an introduction, and the second printing plate 12 refers to the first printing plate 11 .

[0119]The blanking storage bin includes a waste storage bin 131 and a finished product storage bin 132 . The first feeding through hole 111 communicates with the finished product storage bin 132 , and the second feeding through hole 112 communicates with the waste storage bin 131 . The first blanking through hole 111 and the second blanking through hole 112 are respectively rotatably fitted with a printing flap 114 and a waste flap 113 .

[0120] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com