Composite board sawing on-line tracking deburring limiting control device and operation method thereof

A control device and deburring technology, which is applied in the direction of automatic control devices, feeding devices, manufacturing tools, etc., can solve the problems that the finished products cannot be produced fully automatically, there is no better solution, and the surface of the composite board is scratched. It is easy to promote, Compact structure, clean deburring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

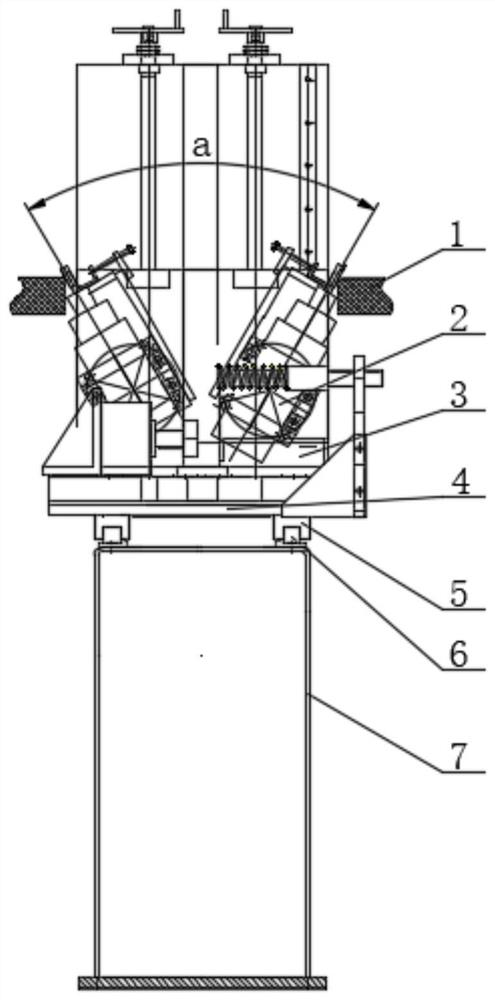

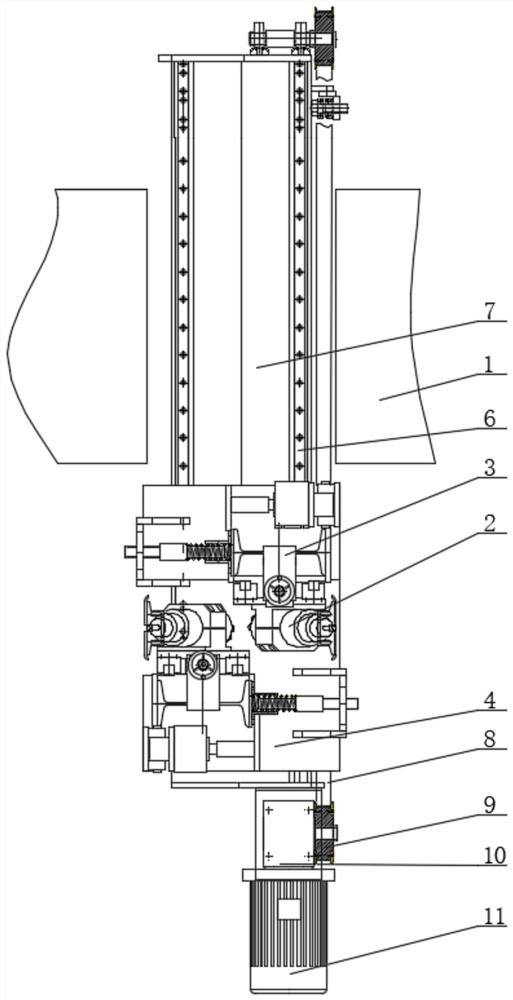

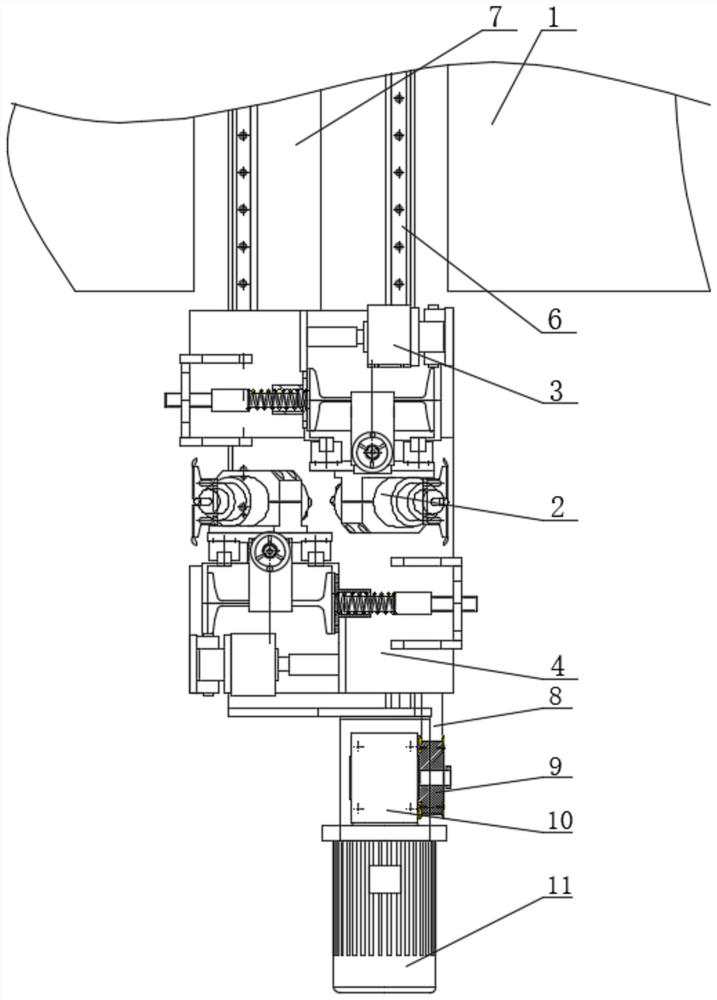

[0062] Such as figure 1 , figure 2 , image 3 As shown, the on-line tracking and deburring limit control device for composite board sawing in this embodiment includes a bracket 7, and first slide rails 6 are installed on the upper surface of the bracket 7 at intervals. The first slider 5 of the first slider 5 is fixedly installed with a carriage 4, and the upper surface of the carriage 4 is oppositely installed with a limit compensation assembly 3 in the longitudinal direction, and each limit compensation assembly 3 is also equipped with a rotary cutting tool Assemblies 2, two rotary cutting tool assemblies 2 are installed back-to-back in the transverse direction of the carriage 4, and a limiting plate 205 is installed at the cutter head 206 at the output end of the rotating cutting tool assembly 2, and the limiting plate 205 and the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com