Compound enzyme preparation for solid-state enzymolysis and application of compound enzyme preparation in wheat bran modification

A compound enzyme preparation and enzymatic hydrolysis technology, applied in the field of food processing, can solve the problem of less influence of physiologically active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the optimization of compound enzyme preparation formula

[0027] Taking cellulase, xylanase, pectinase and β-glucanase as four factors, three kinds of additions were taken for orthogonal optimization experiments, and the four-factor three-level orthogonality design shown in Table 1 was designed. Test table:

[0028] Table 1 Orthogonal test factor level table

[0029]

[0030] Taking the soluble dietary fiber content in wheat bran as the index, see Table 2 and Table 3 for the orthogonal experiment design and range analysis.

[0031] Table 2 Orthogonal test design table and range analysis results

[0032]

[0033]

[0034] Table 3 Orthogonal test analysis of variance table

[0035]

[0036] f 0.01 (2,9)=8.02,F 0.05 (2,9)=4.26; "**" means extremely significant

[0037] It can be seen from the range analysis that when the addition of cellulase and xylanase is at -1 level, and the addition of pectinase is at +1 level, the effect on increasing ...

Embodiment 2

[0039] Embodiment 2: the application of compound enzyme preparation in modified wheat bran

[0040] A compound enzyme preparation, its composition comprises cellulase, xylanase, β-glucanase and pectinase, wherein said cellulase, xylanase, β-glucanase and pectinase The enzyme activity unit ratio of the added enzyme activity of the glue enzyme is 50-100:1:60-90:400-600.

[0041] The application of the above compound enzyme preparation in the modification of wheat bran comprises the following steps:

[0042] (1) Carry out high temperature treatment to wheat bran, the treatment temperature is 100~150 ℃, treatment time is 10~30min;

[0043] (2) uniformly mix the compound enzyme preparation with wheat bran in an additive amount of 10-35%, and add water with a ratio of 1-3:1 to the wheat bran;

[0044] (3) Treating the wheat bran under the conditions of enzymolysis temperature 50-70° C., enzymolysis pH 5-7, and enzymolysis time 1.5-2.5 hours.

Embodiment 3

[0045] Example 3: Effect of compound enzyme preparation on solid-state enzymatic hydrolysis of wheat bran on its physical and chemical properties

[0046] The physical and chemical properties of the wheat bran modified by solid-state enzymatic hydrolysis of the compound enzyme preparation in Example 2 were measured, including microstructure, soluble dietary fiber structure, water / oil holding capacity and swelling force.

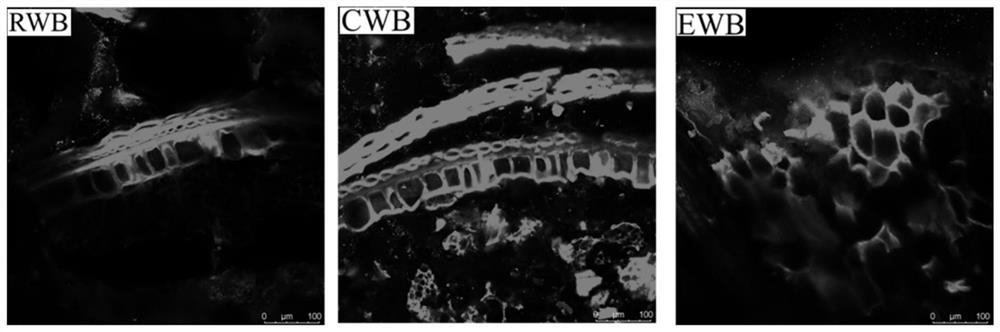

[0047] (1) Effect of compound enzyme preparation on solid-state enzymatic hydrolysis of wheat bran on its microstructure

[0048] The enzymolyzed wheat bran was mixed with 2% agar, and 2.5% glutaraldehyde was fixed in 0.1M phosphate buffer (pH 7.0) for solidification. After tissue dehydration, paraffin embedding, and infiltration, slice with a microtome and transfer to glass slides. The cell wall and protein of wheat bran were stained with Calcofluor White fluorescent whitening agent and Rhodamine B for 1 h, respectively. The changes of wheat bran cell wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com