Silicon-carbon composite material, and preparation method and application thereof

A technology of silicon-carbon composite materials and mixtures, applied in active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of reduced Coulombic efficiency and difficulty in meeting commercial needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

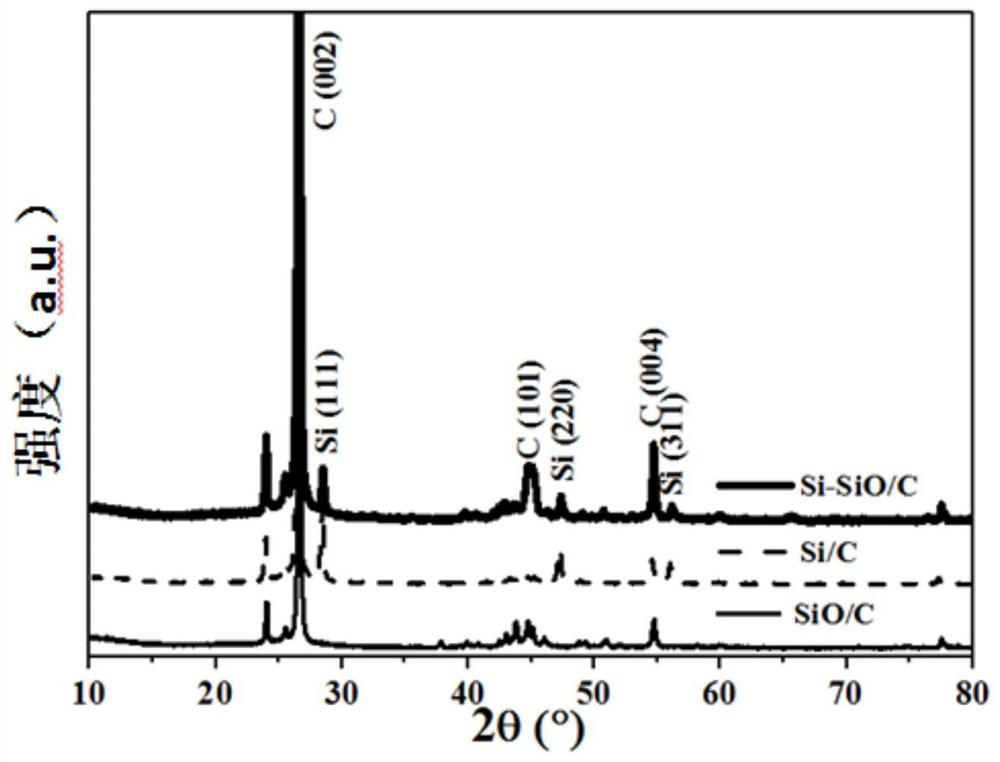

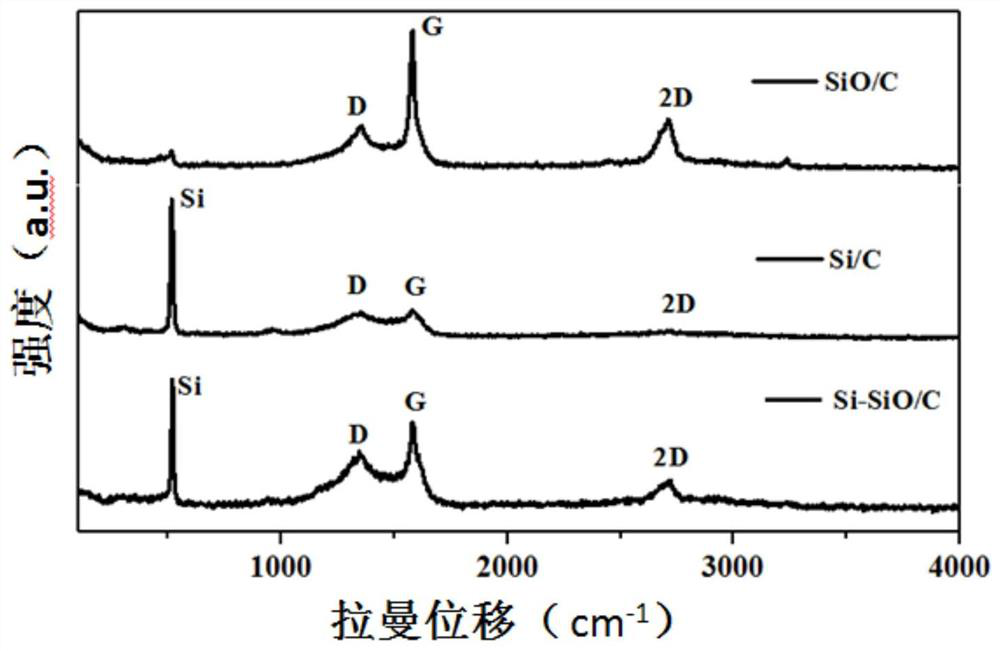

[0036] One aspect of the present invention provides a method for preparing a silicon-carbon composite material, comprising the following steps: uniformly mixing silicon oxide, silicon, an organic carbon source and graphite to obtain a mixture, stirring the mixture in water to obtain a suspension; The precursor is obtained after crushing and drying; the precursor is roasted to obtain a silicon-carbon composite material.

[0037] According to the present invention, silicon oxide (SiO) has good cycle stability as the lithium ion battery negative electrode material, but its first coulombic efficiency is relatively low; Silicon (Si) has better first coulombic efficiency and higher coulombic efficiency as the negative electrode material. Theoretical specific capacity, but its cycle stability is relatively poor. Although the existing methods have been reported to prepare silicon-carbon composite materials by combining the two with carbon sources, none of them can solve the problem of...

Embodiment 1

[0058] (1) Disperse 2g of glucose and 2g of PVP in 150ml of deionized water, add 2g of nano silicon powder (50-150nm) and 2g of SiO (2-5μm) into the above solution, stir at 500rpm for 3h, then add 0.5 g sodium carboxymethyl cellulose (CMC) and 16g of graphite flakes (3500 mesh, Xianfeng Nano) with a particle size of 5 to 10 μm, then added 1.29g of CNTs (accounting for 5% of the total mass), and continued to stir for 0.5h to obtain suspension;

[0059] (2) Transfer the suspension obtained in step (1) to a 500mL stainless steel ball mill tank, add stainless steel balls at a ratio of 10:1 by the ball-to-material ratio, and feed Ar gas into the ball mill tank. The rotating speed ball mill is 8h. The suspension after ball milling was sand milled at a speed of 2200rpm for 0.5h in a sand mill;

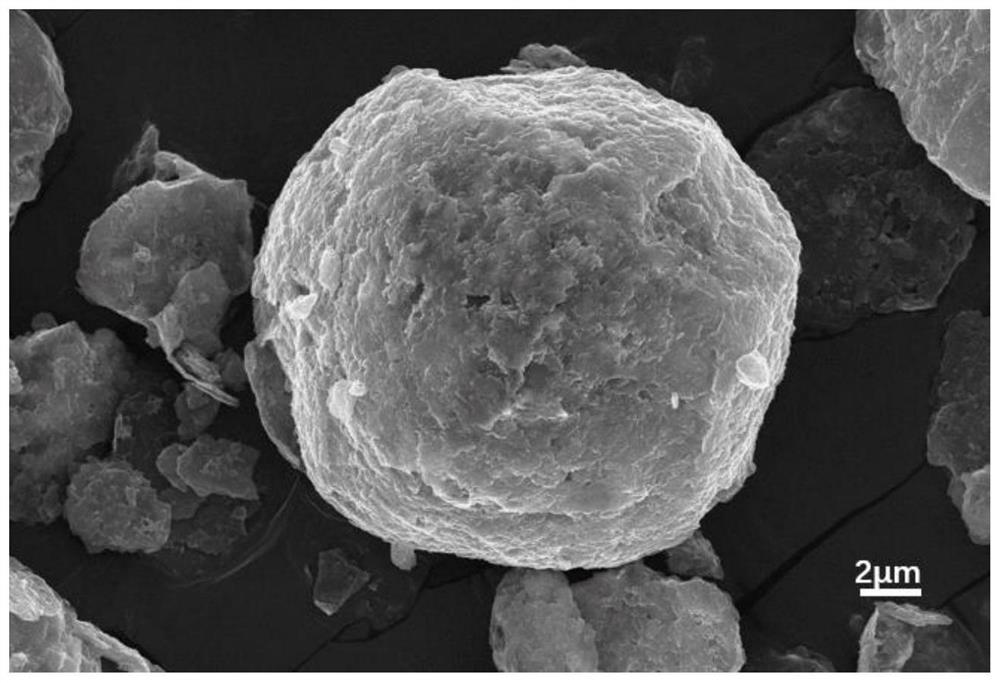

[0060] (3) The slurry after sanding in step (2) was granulated by spray drying, the inlet temperature during spray drying was 180°C, and the outlet temperature was 100°C. Obtain silicon-ca...

Embodiment 2

[0064](1) Disperse 2g of glucose and 2g of PVP in 150ml of deionized water, add 2g of nano silicon powder (50-150nm) and 2g of SiO (2-5μm) into the above solution, stir at 500rpm for 3h, then add 0.5 g sodium carboxymethyl cellulose (CMC) and 16g of graphite flakes (3500 mesh, Xianfeng Nano) with a particle size of 5 to 10 μm, then added 1.29g of CNTs (accounting for 5% of the total mass), and continued to stir for 0.5h to obtain suspension;

[0065] (2) Transfer the suspension obtained in step (1) to a 500mL stainless steel ball mill tank, add stainless steel balls at a ratio of 10:1 by the ball-to-material ratio, and feed Ar gas into the ball mill tank. The rotating speed ball mill is 8h. The suspension after ball milling was sand milled at a speed of 2200rpm for 0.5h in a sand mill;

[0066] (3) The slurry after sanding in step (2) was granulated by spray drying, the inlet temperature during spray drying was 180°C, and the outlet temperature was 100°C. Obtain silicon car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com