A stacked three-dimensional package component structure and fabrication method

A component structure and three-dimensional packaging technology, applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., can solve the problems of poor microwave repeatability, not easy to repair, low reliability, etc., to solve the problem of heat dissipation and matching, Good microwave transmission performance and the effect of improving package integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

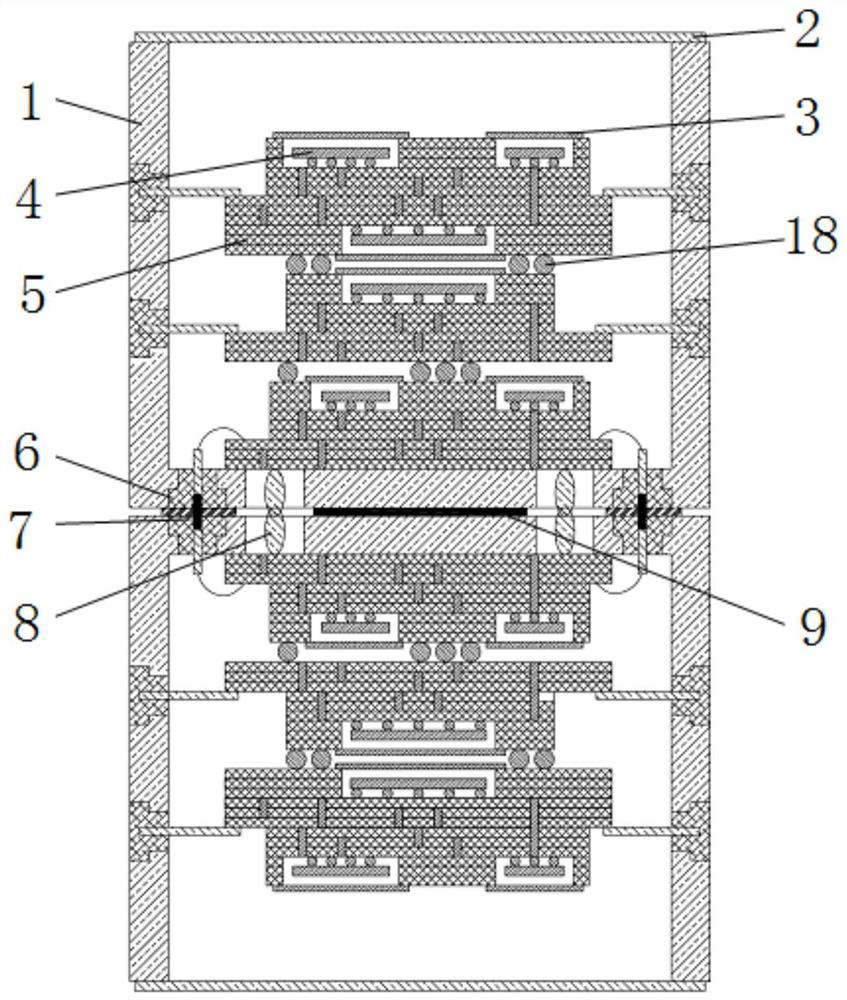

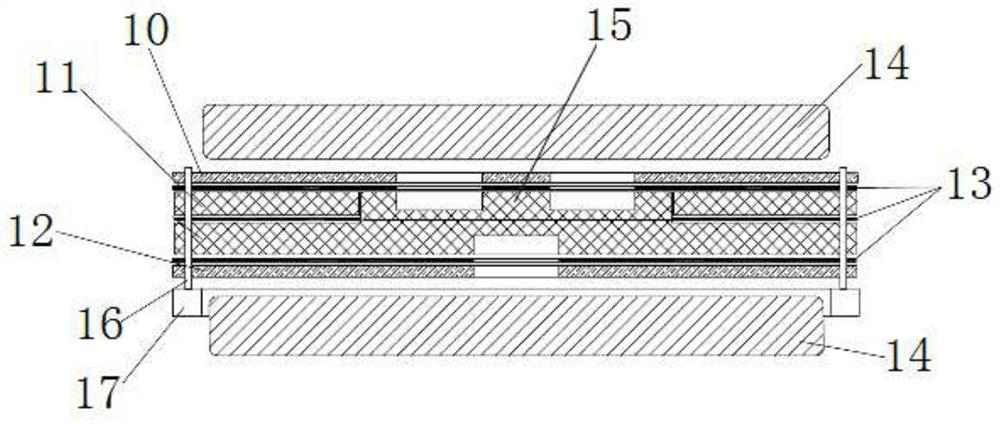

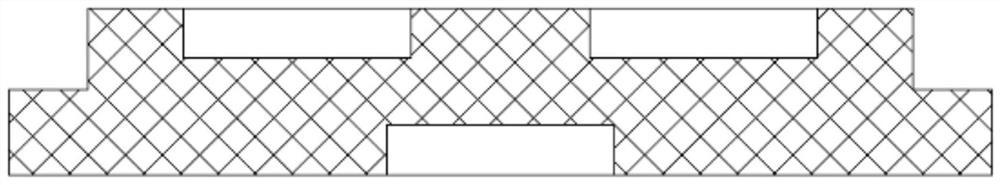

[0062] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0063] In order to overcome the problems in the background technology, the present invention provides a stacked three-dimensional package assembly structure, which is suitable for the preparation of a multilayer ceramic substrate 5 with multiple upper and lower cavities, the vertical interconnection of multiple substrates inside the assembly, and between sub-assemblies. Detachable combination form.

[0064] Generally, it includes several sub-assemblies, each sub-assembly is provided with a transmission port, and adjacent sub-assemblies are interconnected at the transmission port through a consolidation device to realize stacking; The ceramic substrates are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com