Double-signal-response residual chlorine sensor and production method thereof, and detection system

A residual chlorine sensor and dual-signal technology, applied in the photoelectric integrated dual-signal response residual chlorine sensor and its preparation, detection system field, can solve the problems of poor accuracy, influence, low sensitivity, etc., and achieve high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

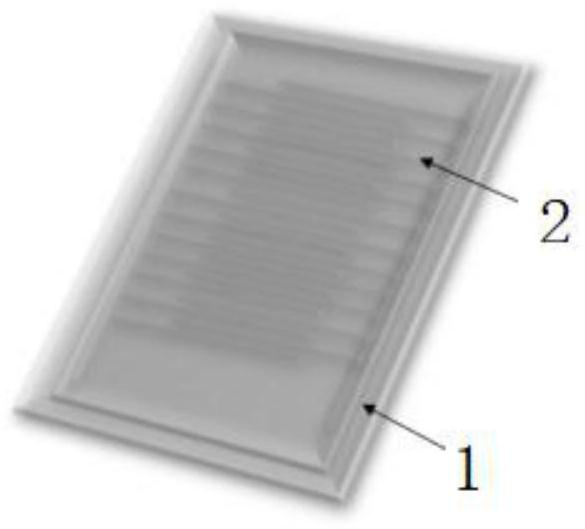

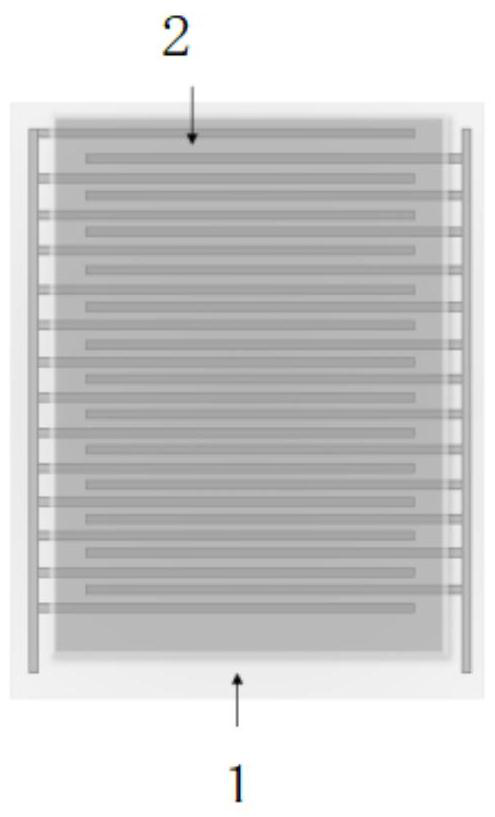

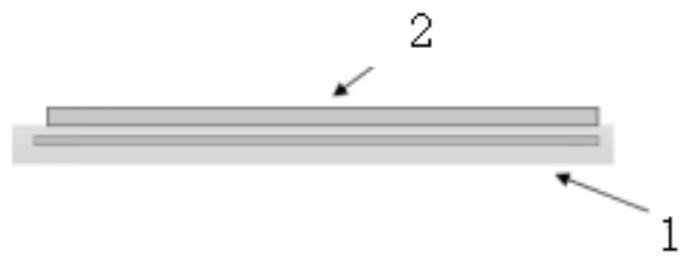

[0031] Refer to 1- image 3 As shown, the residual chlorine sensor 100 with dual signal response includes an interdigital electrode layer 1 located at the bottom as a base, and a sensing layer 2 compounded on the interdigital electrode layer 1 . The sensing layer 2 is a close-packed structure formed by amino-modified MOFs (Metalorganic Framework, metal organic framework compound) three-dimensional photonic crystals. In this embodiment, the residual chlorine sensor can be a rectangular, polygonal, circular hard or flexible sheet integrated sensor.

[0032] The interdigitated electrode layer 1 can be a ceramic-based interdigitated electrode, a PI (Polyimide, polyimide)-based interdigitated electrode, a PET (Polyethylene terephthalate, polyethylene terephthalate)-based interdigitated electrode, a silicon-based interdigitated electrode Electrodes, alumina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com