Double-cylinder compressor pump body and double-cylinder compressor

A compressor pump and double-cylinder technology, applied in the field of compressors, can solve problems such as cracks in the pump oil cover, large space occupied, difficult production management, etc., and achieve the effects of prolonging service life, avoiding occupying space, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

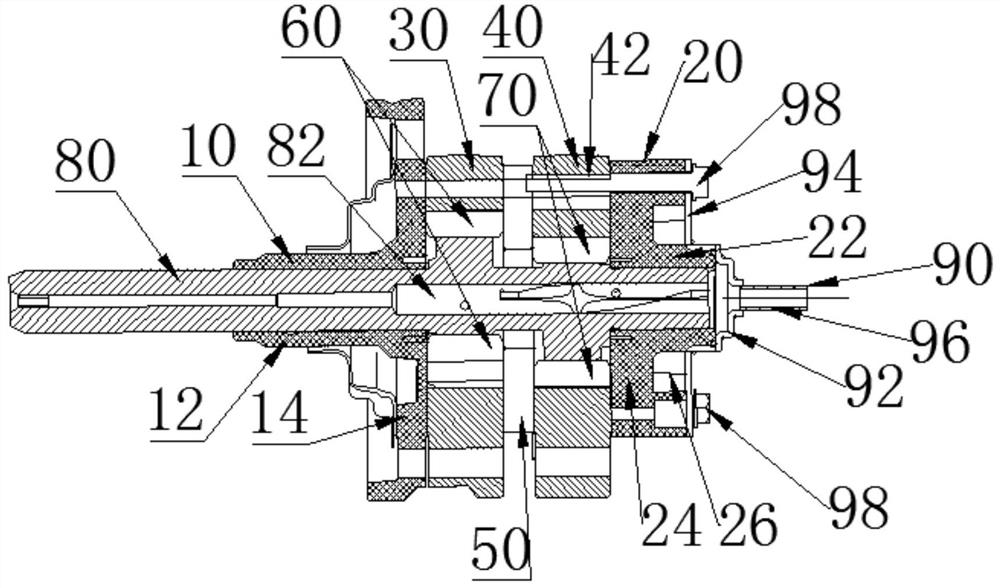

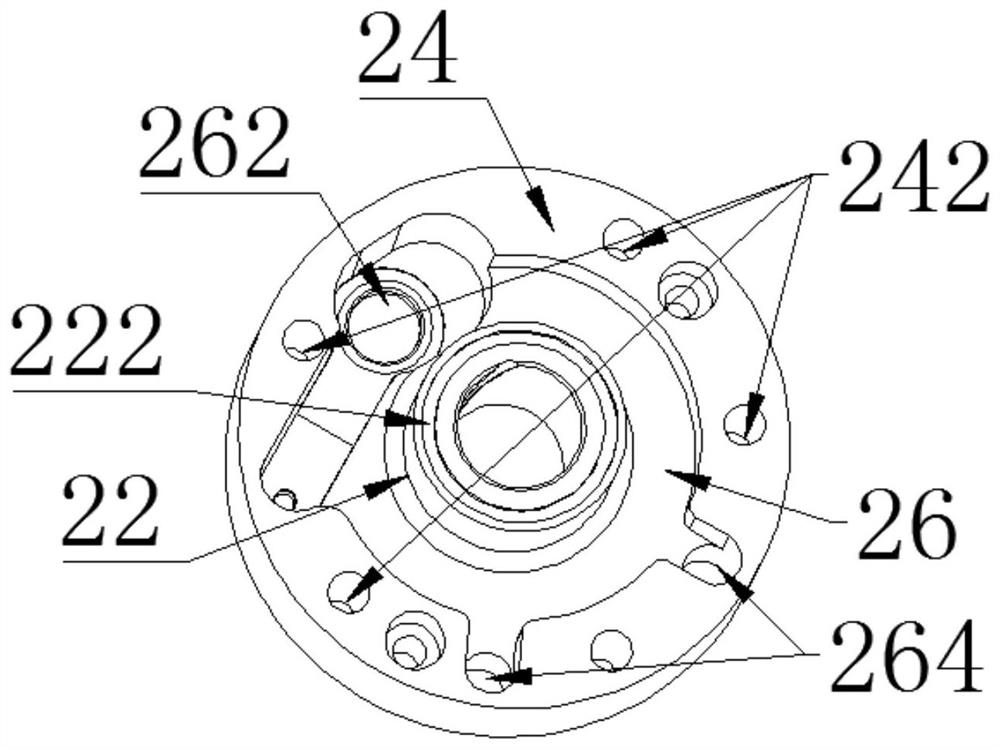

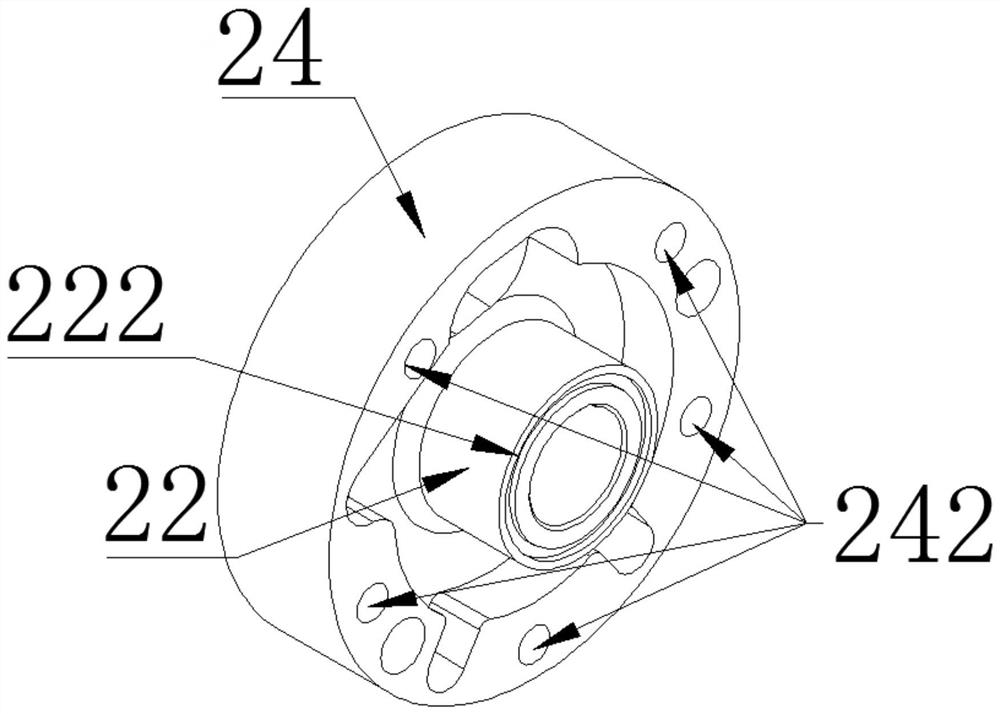

[0032] Please refer to Figure 1-3 , figure 1 It is a schematic cross-sectional view of the double-cylinder compressor pump body described in Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the structure of the second bearing angle described in Embodiment 1 of the present invention, image 3 It is a schematic diagram of the structure of the second bearing angle 2 described in Embodiment 1 of the present invention. As shown in the figure, Embodiment 1 of the present invention provides a double-cylinder compressor pump body, which includes a first bearing 10, a second bearing 20, a first The cylinder 30 , the second cylinder 40 , the middle plate 50 , the first piston 60 , the second piston 70 , the crankshaft 80 and the oil pump cover 90 .

[0033] The first bearing 10, the first cylinder 30, the middle plate 50, the second cylinder 40, and the second bearing 20 are sequentially detachably fixed and enclosed into two independent refrigerant compr...

Embodiment 2

[0043] Please refer to Figure 6-8 , Figure 6 It is a schematic cross-sectional view of the double-cylinder compressor pump body described in Embodiment 2 of the present invention, Figure 7 It is a schematic explosion diagram of the pump oil cover and the second bearing structure in Embodiment 2 of the present invention, Figure 8 It is a schematic side view of the oil pump cover described in Embodiment 2 of the present invention. As shown in the figure, Embodiment 2 of the present invention provides a pump body of a double-cylinder compressor, which is different from Embodiment 1 in that it is applied to a horizontal compressor, and the pump body of the double-cylinder compressor is horizontal. As an optional implementation, in this embodiment, the oil suction pipe 96 has a three-section structure, which includes a first pipe section away from the cover body 92, and the extension direction of the first pipe section is parallel to the axial direction of the crankshaft 80, ...

Embodiment 3

[0048] Embodiment 3 of the present invention provides a double-cylinder compressor, which includes the pump body of the above-mentioned double-cylinder compressor. The double-cylinder compressor described in Embodiment 3 of the present invention has simple structure, high mechanical strength, long service life, high processing and assembly efficiency, good lubrication effect during operation, and is not prone to structural damage due to dry friction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com