Low-temperature dyeing process of environment-friendly regenerated polyester yarns

A recycled polyester, low-temperature dyeing technology, applied in the field of yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

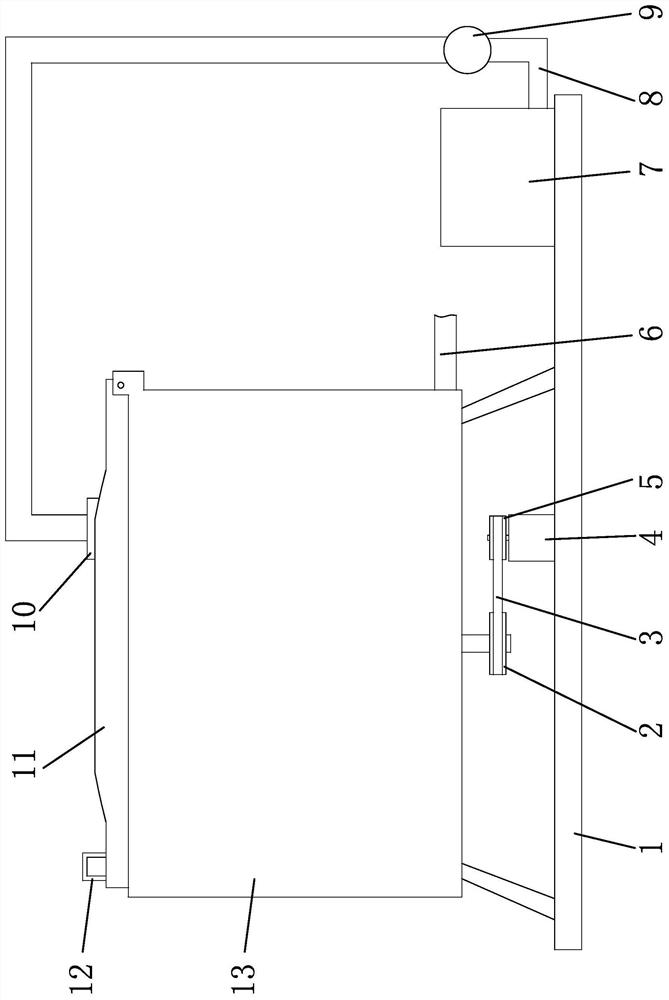

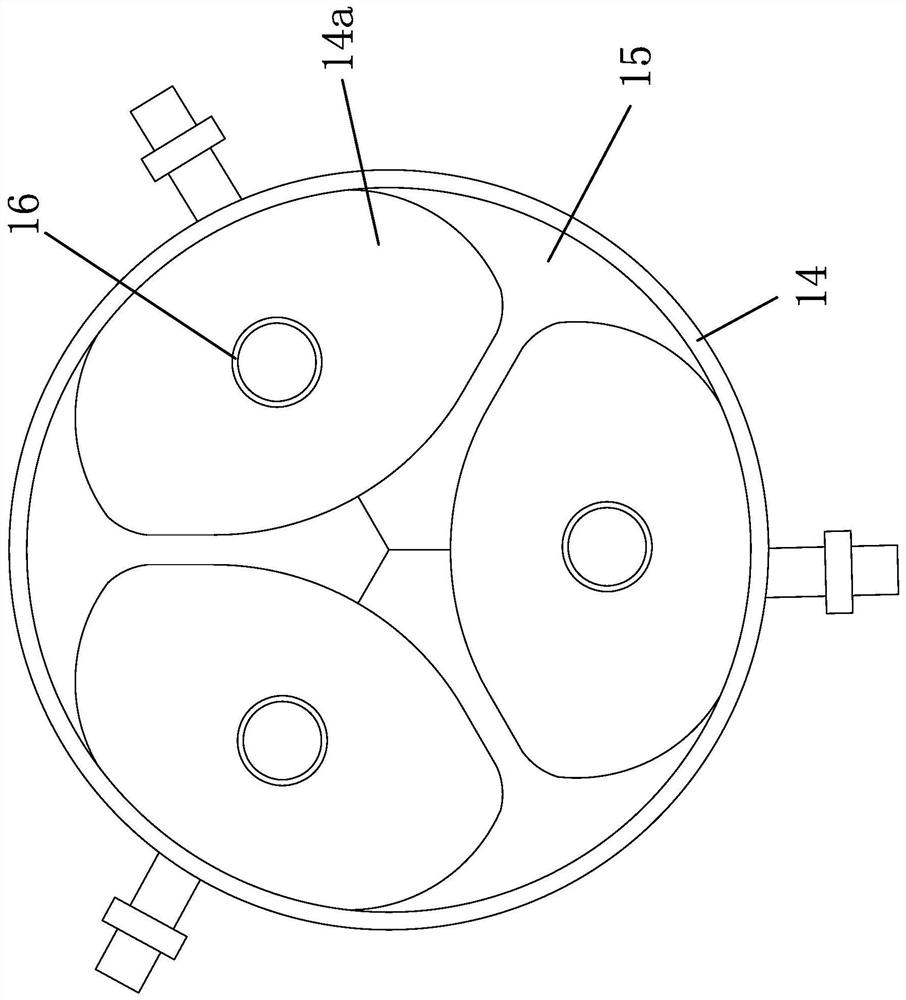

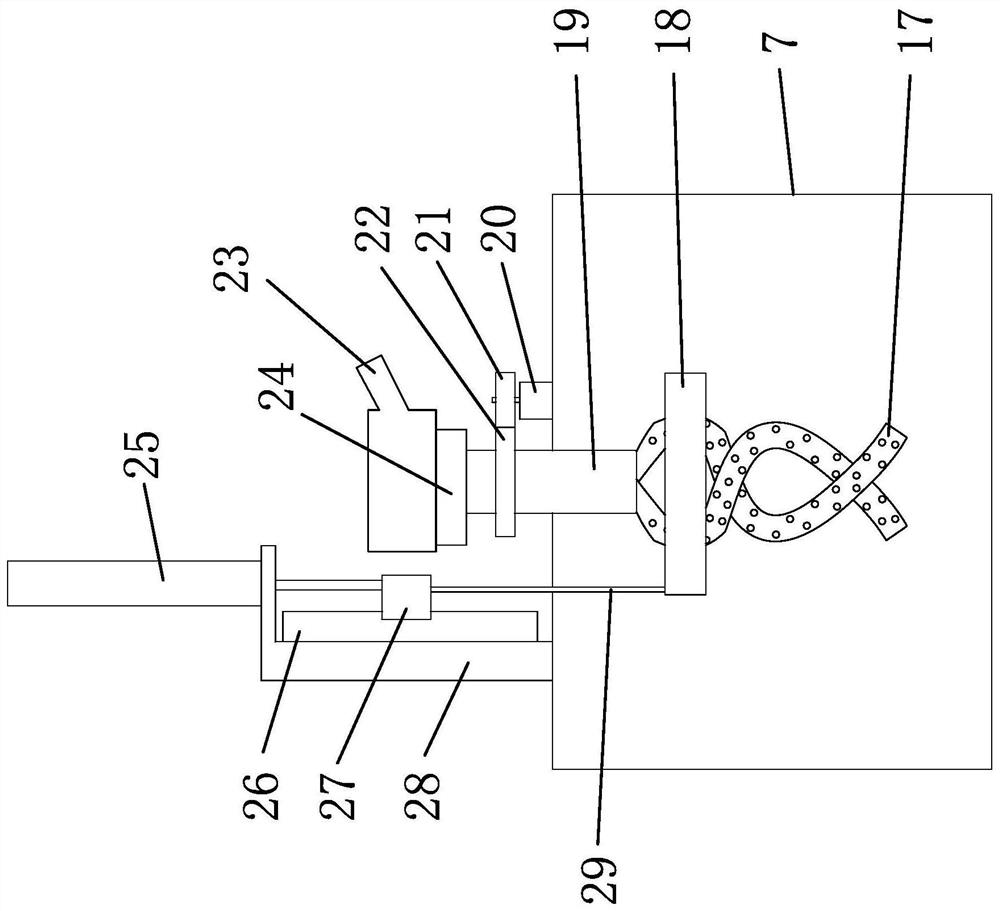

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0032] Such as Figure 1-Figure 7 As shown, the low-temperature dyeing process of environmentally friendly regenerated polyester yarn includes the following steps: put the regenerated polyester yarn into an energy-saving yarn dyeing device, add dye guide agent, glacial acetic acid and dyes and run for 5-15 minutes, press Raise the temperature at a rate of 1°C / min to 90°C and keep it for 10 minutes, then raise the temperature at a rate of 1°C / min to 100°C and keep it for 30 minutes, cool down to 50-60°C, and drain the liquid. In this example, both the dye guide and the dye Existing products available on the market are used.

[0033] The dyeing bath ratio is 1:2.

[0034] The energy-saving yarn dyeing device comprises a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com