Wear-resistant high-transmittance super-smooth PU open-type matte varnish and preparation method thereof

An open, clear topcoat technology, applied in the field of coatings, can solve the problems of poor surface effect, paint film not resistant to scratches, no real wood feeling, etc., achieve low VOC content, improve paint film hardness and yellowing resistance , Improve the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with examples, which are only preferred implementations of the present invention, and are not limitations of the present invention.

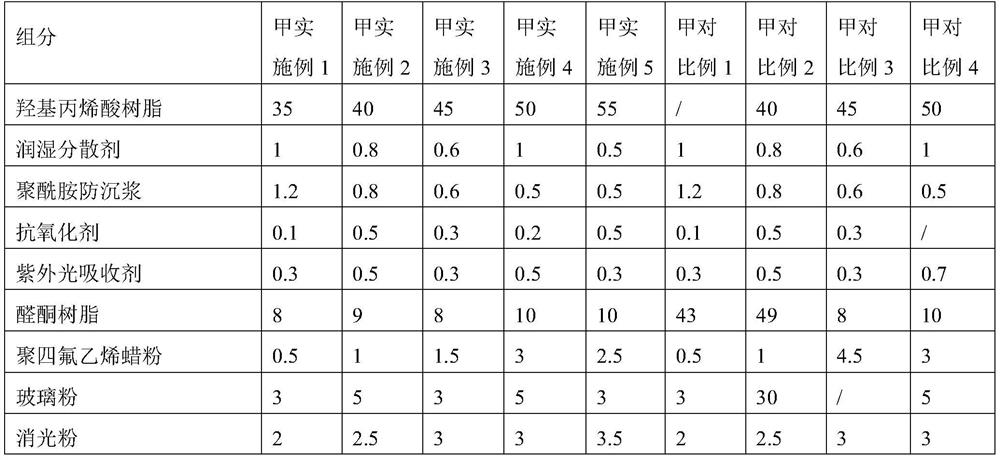

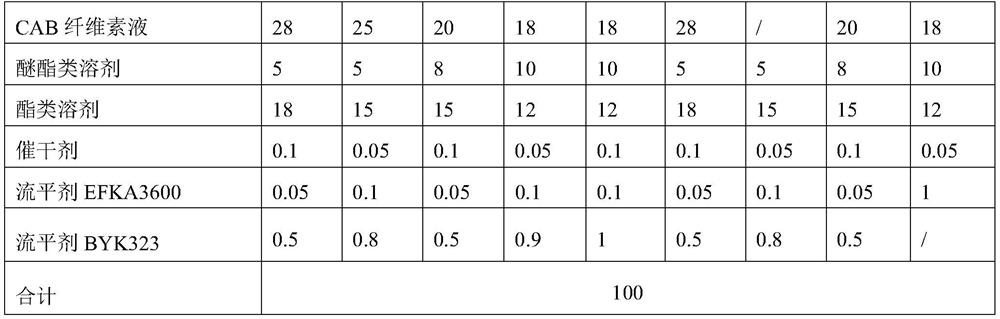

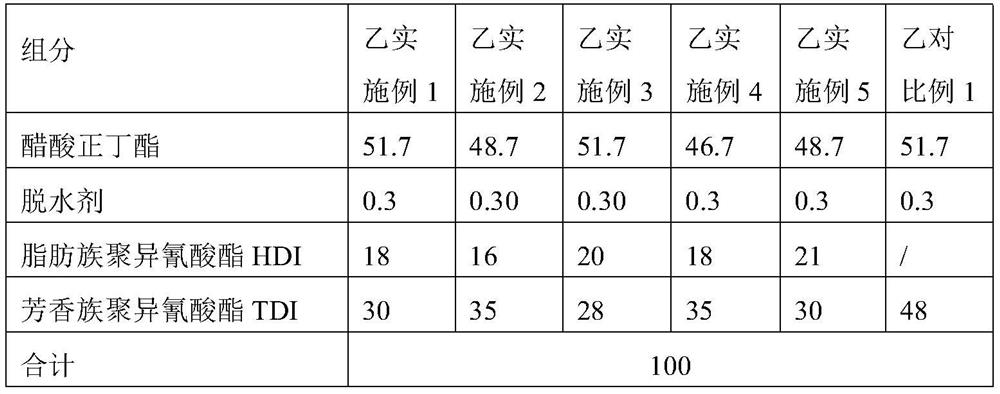

[0032] In the examples and comparative examples of the present invention, the hydroxy acrylic resin used is Deqian FS-4660, the wetting and dispersing agent is EFKA-4010, the polyamide anti-settling paste Deqian 292, the antioxidant is 1010, and the ultraviolet absorber is UV- 531, aldehyde and ketone resin is A81, polytetrafluoroethylene wax powder is Clariant 9615A, glass powder is Japan Changnai VX-SP, matting powder is ED-2, CAB cellulose is CAB-381-0.5, ether ester solvent PMA, ester solvent is BCA, drier is T-12, leveling agent is EFKA3600, BYK323, n-butyl acetate is BAC, dehydrating agent is TI, aliphatic polyisocyanate HDI is N3390, aromatic polyisocyanate TDI For D-262T.

[0033] A component

[0034] The following table is the formula table (unit: %) of 5 em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com