Multi-station polishing machine

A polishing machine and multi-station technology, which is applied in the direction of grinding frame, grinding machine parts, grinding machines, etc., can solve the problems of difficult grinding of multiple curved line products, inability to use universally, and high cost, so as to improve quality , Increase the effect of grinding consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

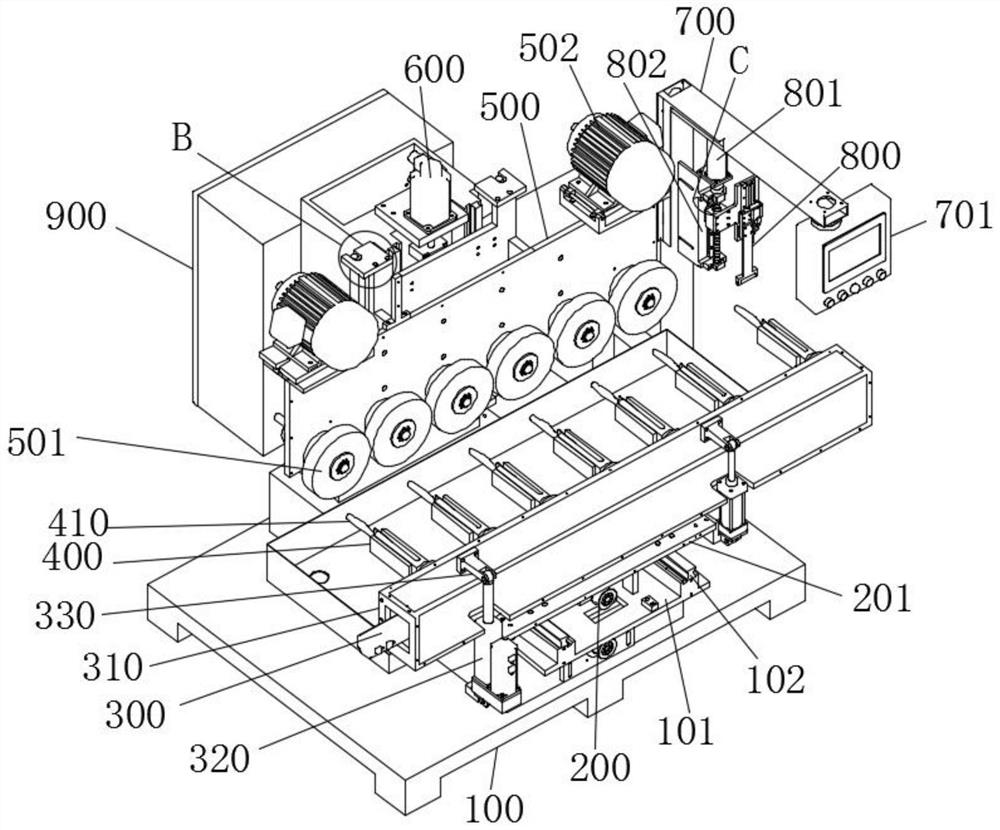

[0055] see Figure 1-Figure 11 , the present invention provides a technical solution:

[0056] A multi-station polishing machine, comprising:

[0057] A base 100, a positioning plate 101 is fixedly installed above the base 100, and a reinforcing rib 110 is welded on the bottom of the base 100;

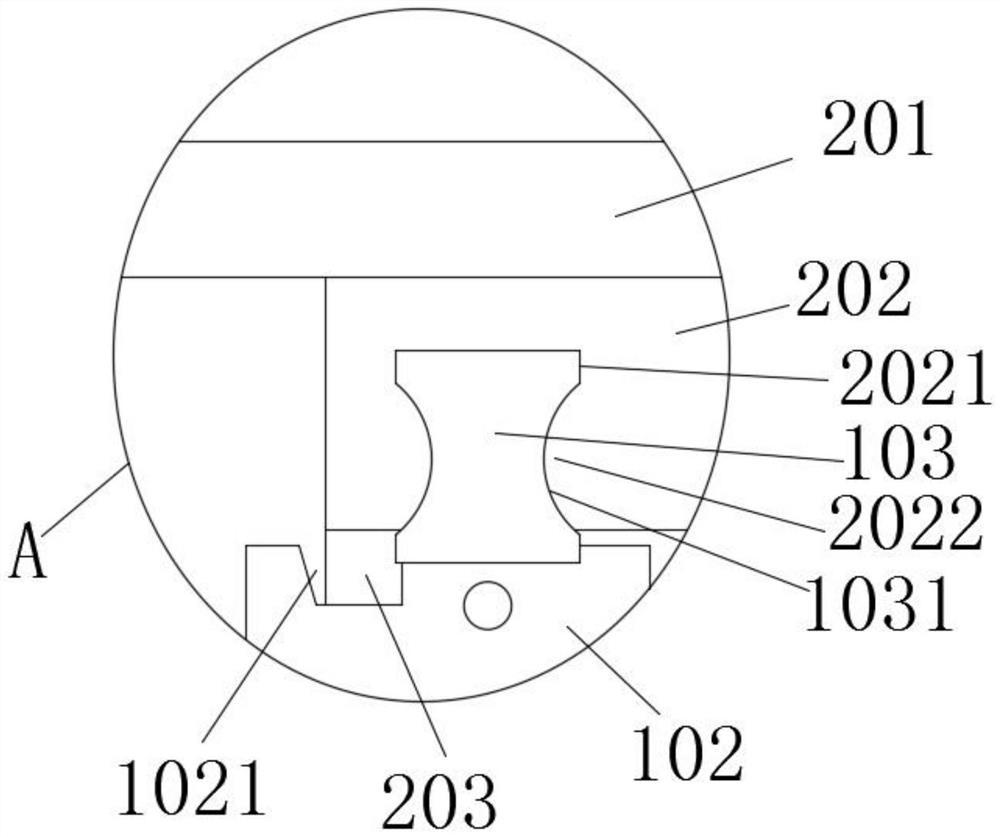

[0058]Front and rear movement mechanism, front and rear movement mechanism comprises front and rear driving cylinder 200 and front and rear moving plate 201, and front and rear driving cylinder 200 drives front and rear moving plate 201 to move back and forth above the top of positioning plate 101; the left and right sides of the top of positioning plate 101 are equipped with longitudinal rail 102, the top of the longitudinal rail 102 is integrally formed with a longitudinal slide rail 103, the left and right sides of the bottom of the front and rear moving plate 201 are welded with sliders 202, and the bottom of the slider 202 is provided with a chute that is engaged with the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com