Automatic bowl ball production line

An automated production line and bowl ball technology, applied in the field of food processing, can solve the problems of unstable production quality, low production efficiency, and short product shelf life, and achieve the effects of controllable quality, high production efficiency and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

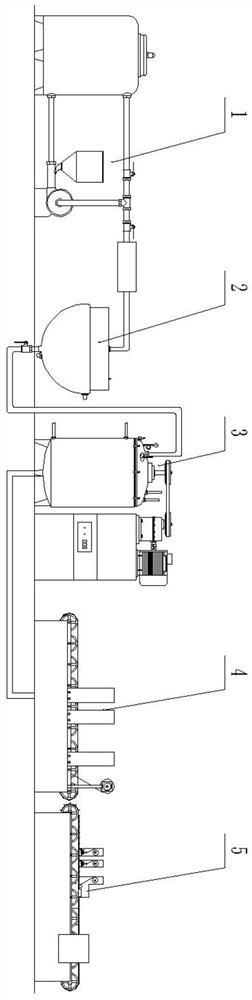

[0070] Such as Figure 1 to Figure 12 Described: the bowl automatic production line of the present invention comprises: noodle paste production device 1, preheating temporary storage device 2, ripening device 3, shaping and sealing device 4 and packaging device 5; The storage device 2, the curing device 3 and the sizing and sealing device 4 are connected by pipelines, and the output of the sizing and sealing device 4 is transferred to the packaging device 5 for packaging production.

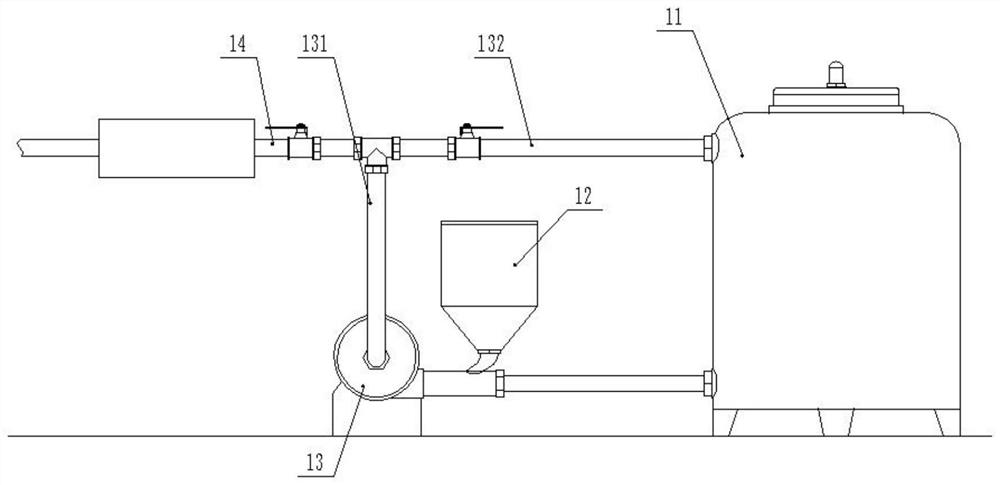

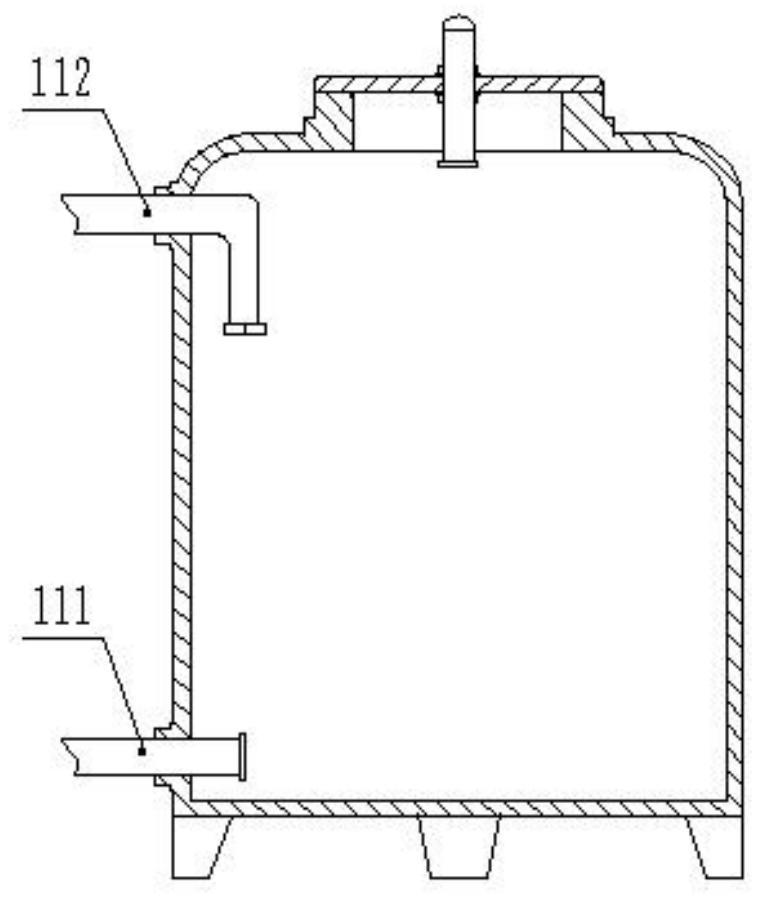

[0071] The noodle production device 1 comprises: a water storage tank 11, a noodle storage tank 12, a homogeneous pump 13 and a noodle slurry discharge pipe 14; the water storage tank 11 is provided with a water outlet 111 and a circulating water inlet 112, so The water outlet 111 is set at the lower end of the water storage tank 11, the circulating water inlet 112 is set at the upper part of the water storage tank 11, the water outlet 111 communicates with the feed port of the homogeneous pump 1...

Embodiment 2

[0083] Such as Figure 1 to Figure 12 Described: the bowl automatic production line of the present invention comprises: noodle paste production device 1, preheating temporary storage device 2, ripening device 3, shaping and sealing device 4 and packaging device 5; The storage device 2, the curing device 3 and the sizing and sealing device 4 are connected by pipelines, and the output of the sizing and sealing device 4 is transferred to the packaging device 5 for packaging production.

[0084] The noodle production device 1 comprises: a water storage tank 11, a noodle storage tank 12, a homogeneous pump 13 and a noodle slurry discharge pipe 14; the water storage tank 11 is provided with a water outlet 111 and a circulating water inlet 112, so The water outlet 111 is set at the lower end of the water storage tank 11, the circulating water inlet 112 is set at the upper part of the water storage tank 11, the water outlet 111 communicates with the feed port of the homogeneous pump 1...

Embodiment 3

[0096] Such as Figure 1 to Figure 12 Described: the bowl automatic production line of the present invention comprises: noodle paste production device 1, preheating temporary storage device 2, ripening device 3, shaping and sealing device 4 and packaging device 5; The storage device 2, the curing device 3 and the sizing and sealing device 4 are connected by pipelines, and the output of the sizing and sealing device 4 is transferred to the packaging device 5 for packaging production.

[0097] The noodle production device 1 comprises: a water storage tank 11, a noodle storage tank 12, a homogeneous pump 13 and a noodle slurry discharge pipe 14; the water storage tank 11 is provided with a water outlet 111 and a circulating water inlet 112, so The water outlet 111 is set at the lower end of the water storage tank 11, the circulating water inlet 112 is set at the upper part of the water storage tank 11, the water outlet 111 communicates with the feed port of the homogeneous pump 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com